Pas mehanizma distribucijskega omrežja zemeljskega plina je nepogrešljiv atribut za večino sodobnih vozil, vključno s tistimi za Chevrolet Lacetti avto. Kljub izjemno preprostost, to je precej pomembna podrobnost pri motorju z notranjim zgorevanjem. Zamenjava jermena na Chevrolet Lacetti - dogodek je precej zamudno, vendar je povsem preprost, če ravno deluje pod navodili.

Vsebina

- Časovni pas, katere naloge storiti jermen

- Časovni pas, ki deluje, in od česa materiala

- Kako pogosto spreminjajo jermen

- Koliko spremeniti časovni pas, kaj znaki govorijo o potrebi za zamenjavo jermen

- Zlomil jermen, ki vodi takšno razčlenitev

- Jermen, zakaj je zamenjava pasu bolje narediti v kompletu

- Orodja, napeljave, potrošni material

- Varnostna tehnika

- Zamenjava jermena Chevrolet Lacetti, korak za korakom delo

- Nasveti Profi, kako preveriti napetosti jermena

Časovni pas, katere naloge storiti jermen

Naloga je, da odmično gred vrti s hitrostjo, povsem enako polovico prometa ročične gredi. Pol stoletja, je bil pogon GRM verige se uporabljajo v avtomobilski industriji, in vsi poskusi, da se prilagodi pas za to so nesporazum. Veliko časa je preteklo, preden je pogonski jermen začel prevladovati. Ampak on ima več pomembnih prednosti - poenostavitev dizajn, nizka raven hrupa in zmanjšanje mase agregata.

Danes, proizvajalci raje namestiti pogone pas na svoje avtomobile. Ampak to je nemogoče nedvoumno povedati, da je veriga slabše od pasu. Pogonska veriga ima tudi svoje prednosti - vzdržljivost, v korelaciji s trajanjem samega motorja. Zato je tudi v našem času, nekatera proizvodna podjetja končati svojo odločitev o mehanizmu verige. Poleg tega so taki motorji običajno opremljeni z avtomatskimi napenjalci. Življenjska doba običajnem pasu zelo redko preseže 60 tisoč kilometrov, in preprostost modela pomeni, da je treba za stalno službo - pull-up, zamenjavo, nadzor nad stanjem pasu.

Časovni pas, ki deluje, in od česa materiala

Da bi jermena zanesljivo deluje, je treba upoštevati naslednje pogoje - optimalno stanje jermenice in valji, po kateri je pas odselili, pravilno napetost jermena, njegovo absolutno zaščito pred oljem in umazanijo. Zasnova pasu je zelo preprosta in kar spominja pnevmatiko avtomobila.

Zato je večina podjetij, ki so specializirani za proizvodnjo pnevmatik proizvajajo tudi pasove. Osnova za časovni pas - kabel - za pleksus trajnih niti iz steklenih vlaken. Notranji kabli oglas zobje iz obrabno odpornih materialov (praviloma, najlona), in zunaj ščiti plast gume, katerih debelina je približno pet milimetrov. Zasnova pasov je zelo raznolika. To se lahko razlikujejo v širini pasu, število in korak zob, kot tudi njihov profil (obstaja približno dvajset vrst profilov zob).

Kako pogosto spreminjajo jermen

Zamenjava jermena na Chevrolet Lacetti, v skladu s predpisi za vzdrževanje, je treba opraviti na vsakih 60.000 prevoženih kilometrov kilometrov. Vendar pa je večina strokovnjaki priporočajo, da se zmanjša spremembo nadomestni obdobju zaradi zapletenih pogojev poslovanja. Kot je za preverjanje stanja na pasu, nato pa na avto Chevrolet lacetta treba opraviti na vsakih 30 tisoč kilometrov.

Koliko spremeniti časovni pas, kaj znaki govorijo o potrebi za zamenjavo jermen

- Nošenje materiala. Jermen lahko obrabijo na enak način kot, na primer, pnevmatiko. Če se material pas obrabljena, se lahko zgodi, da jo odprete ali zdrsa. Še posebej pogosto se to zgodi pri velikih obremenitvah na motorju motorja. Na primer, ko sledenje priklopnika ali priklopnik, kot tudi v mokrem vremenu.

- Pas abrazijo. To se zgodi, praviloma z odklonom škripca in natezalno kolesce iz zadnjega položaja, pa tudi, ko okvari ležajnega in povišani temperaturi. V primeru inšpekcijskega pregleda, ki jih lahko opazimo na obrabo zob pas - svojo bazo tkiva (razširjene tkanine vlakna in neenakomerno teksturo).

- Nenavezanost ali razpoke. Ta značilnost delovanja je očitna. Treba je raziskati zadnjo in sprednjo površino pasu. Prisotnost razpok, še posebej, če jih je veliko, kaže na močno obrabljeno.

- Kaljenje nasprotno površino zobatega jermena je nasprotna površina traku je težko, ni elastičen in bleščice. V tem primeru postane pas nenatanljiv, saj rezultat tega ne zagotavlja več želenega stika z jermenico.

- Raztezek. Materialna obraba je sposobna voditi močan razteznost pasu, zaradi česar se napetostni valj presega dopustne meje. To zmanjšuje togost in skupno napetost pasu in posledično splošne zmogljivosti mehanizma.

- Odstopanje od določenega položaja. Ta funkcija označuje, da so notranji elementi napenjalnega valja precej blizu lomu. Če valj ne uspe, bo vodilo k povečanju hrupa, temperature in vibracij.

Zlomil je pas, ki vodi takšno okvaro

Zruček krmilnega pasu lahko vključuje maso neprijetnih posledic, ki se razlikujejo, od potrebe po zamenjavi krmilnega jermena in obnovitev distribucijskega mehanizma za plin in remont motorja.

Najtežja situacija je, ko je ventil upognjen kot rezultat pasu. To je preprosto razloženo. Vrzel lahko zgodi v obdobju, ko se ventili padla za vbrizgavanje goriva ali sproščanje plinov. Ob istem času, gibanje batov v valjih se še vedno nadaljuje in da so mogli zadeti iz vseh nad silo. V tem primeru se lahko "srečanje" konča precej slabo.

Ocenite stopnjo škode lahko oceniti šele potem, ko razstavljamo glavo motorja in ocenite stanje batnega sistema in ventilov. Opozoriti je treba, da napajanja ventila ne more takoj videti - za diagnostiko zahteva posebno opremo.

Jermen, zakaj je zamenjava pasu bolje narediti v kompletu

Da bi se izognili težavam v prihodnosti, zamenjava jermena, je zaželeno, da se pripravi skupaj z črpalke in valji. To ni obvezno ukrepanje, če pa so dodatna sredstva, je najbolje, da ne bodi len, ker bo to vplivalo na učinkovitost novega jermena.

Poleg tega, da izpolni zamenjavo, boste morali v celoti razstaviti vseh sestavnih delov te opreme, vključno s črpalko z valji. Tako je zamenjava potrošnega stroški tega postopka ne bo povečala toliko, in da ne bo trajalo veliko časa, vendar pa se bo povečala življenjsko dobo nadomesti agregata.

Orodja, napeljave, potrošni material

- Voditelji na "10", "12", "14", "17", "32".

- Nastavljiv poudarek.

- Šesterokotnik na "5".

- Ključ do "41".

- Passatia.

Varnostna tehnika

Nemogoče je, da delo pod vozilom, če je objavljen le na vtičnico. Kot zavarovanja v obvezno uporabite Pogoj postajo Factory. Prepovedano je, da visi avto na dva ali več priključkov. Da bi zaščitili svoje roke od odrgnine in kosi z operacijami "moč", bi morali delati v rokavice.

Zamenjava jermena Chevrolet Lacetti, korak za korakom delo

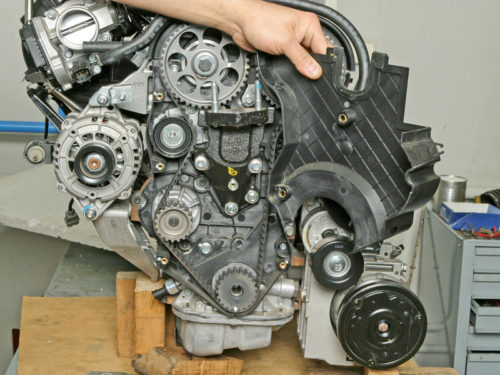

- Odprite pokrov in razstaviti dekorativno oblogo z motorjem, za katerega boste morali odvijte štiri matice.

- Za udobje, razstaviti ohišje zračnega filtra. Če želite to narediti, s pokrovom zračnega filtra, smo odvijte štiri vijake, kot tudi plast zraka šobe. Mi razstaviti pokrov in zračni filter. Za odstranitev ohišje filtra sam odviti dva vijaka.

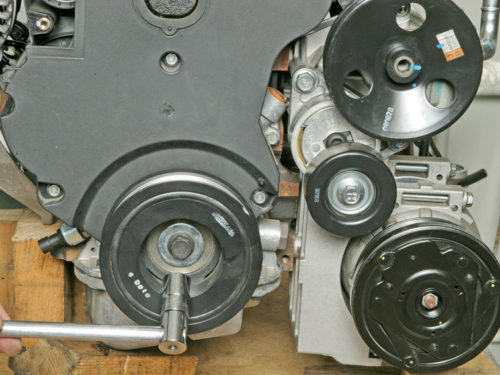

- Sedaj odstranite jermen - potegnite valja pogona s tipko za "17" in razstaviti pas iz škripcev. Nato morate odviti dva vijaka in odstranite zgornji pokrov pokrova krmiljenja.

- Izdelujemo odstranitev prednjega desnega kolesa in bočne Anther motorja, ki je pritrjen na tri bati in dvema vijakoma.

- Mi odvijte Jermenice motorne gredi, za katerega se določi vztrajnik z uporabo velike podolgovata izvijač skozi okno gledanja. Nato je z nacistično in glavo na "17" smo odvijte in razstaviti Jermenice motorne gredi.

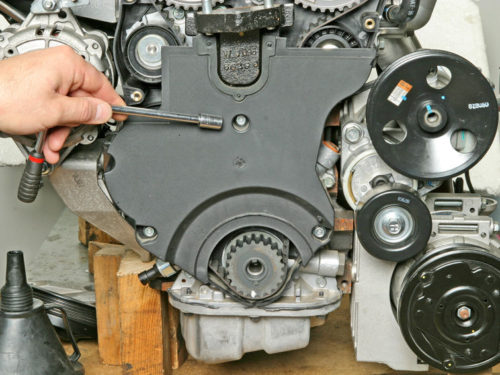

- Prav tako odstranite spodnji pokrov jermena, ki je pritrjena s tremi zob.

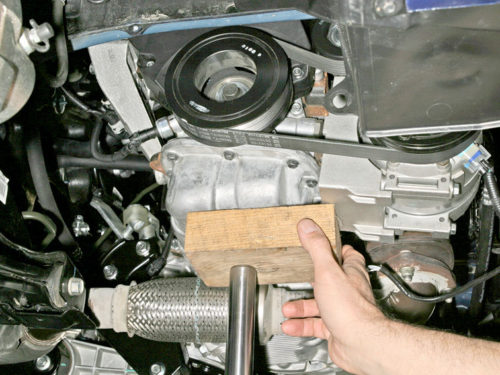

- Naslednji korak je, da se odstranijo podporo motorja, za kaj morate namestiti dodaten priključek za napajanje enote pod palete. Potem smo odviti 3 oreške in 1 vijak s tipko za "14" in razstaviti podporo OBS.

- Mi odvijte štiri vijake po obodu nosilne sponke in odstranite nosilec.

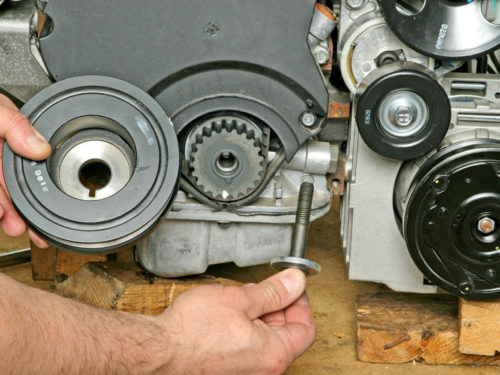

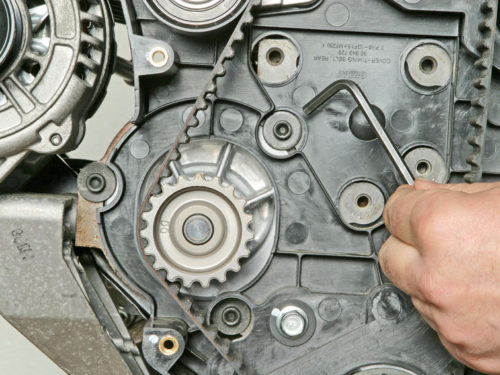

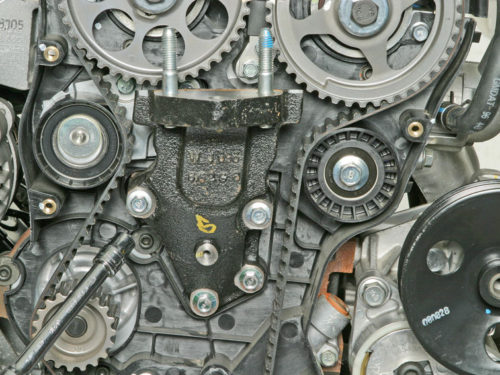

- Poleg tega je na vse jermenice, smo postavili oznake časovne. Na jermenice motorne gredi bo v nadaljevanju.

- Za udobje vrtenja ročične gredi, zategnite jermenico vijak nazaj.

- Sedaj nadaljuje z zamenjavo jermen. S tipko za "14", smo odvijte parazitski valj, ki se nahaja na desni strani in razstaviti pas, po katerem smo odvijanje valja napenjalec, ki je pritrjen s tremi vijaki.

- Pred namestitvijo jermena preverite oznake, ker se po odstranitvi lahko ugasnejo.

- Ko je še vedno samo nositi pas na črpalki, premikanje valja napenjalo, potem pa se je do konca traku in preverite namestitev oznak.

- Nato se pomaknite motorne gredi v smeri urinega kazalca na enem ali dveh zavojih in še enkrat preverite oznake.

Nasveti Profi, Kako preveriti napetost zobatega jermena

Za preverjanje napetosti jermena zavrtite motorno gred dva do trikrat desno in pogled na kolesce zob. Potrebno je, da so stali nasproti drug drugemu - plus-minus nekaj milimetrov. Če odčitki razlikujejo, boste morali prilagoditi napetost jermena s pomočjo črpalke.

Podobni materiali

- Štedilnik 2110, slab topel štedilnik 2110, VAZ 2110 ogrevalnega sistema, Popravilo ogrevalnega sistema VAZ 2110 s svojimi rokami

- VAZ 2114 Štedilnik s hladnim zrakom, štedilnikom 2114, slabim toplim štedilnikom VAZ 2114, naprava in popravilo ogrevanja VAZ 2114 DO-IT-YOUR-PASS, Odstranjevanje štedilnika VAZ 2114

- Kako poddominizirati avto. Kako postaviti Jacka. Vrste priključkov za avtomobile.

- VAZ 2109 varovalka, VAZ 2109 Vaz Block Block Carbubur, VAZ 2109 varovalka Block, Old VAZ 2109 varovalka, VAZ 2109 varovalka, VAZ 2109

- Car izpušni plinski katalizator, napačen katalizator, pluse in slabosti katalizatorja, kako spremeniti katalizator na planeeencitel

- Štedilnik piha hladen zrak VAZ 2114, slabo piha peči VAZ 2114, zakaj slabo piha števec VAZ 2114

- Kako izvedeti lastnika avtomobila s številom njegovega avtomobila, preverite avto s številom prometne policije stroj, preverite avto z državo številko avtomobila brezplačno

- Kako izbrati rabljene pnevmatike, koristni nasveti

- Zimska avtomobilska cesta, pritisk v pnevmatikah osebnih avtomobilov pozimi, dobra baterija za avto pozimi, bodisi tople avto v zimskem času

- V zimskem času se avto slabo začenja. Kako narediti avto pozimi, ali se morate ogrevati avto pozimi, koristne nasvete

- Stroji za porabo porabe goriva, najbolj ekonomična poraba avtomobilov

- Pnevmatike blagovne znamke za osebne avtomobile, označevanje avtomobilske pnevmatike, preostale osebni avtomobilski pnevmatike, kako izbrati pnevmatiko na blagovno znamko avtomobila, avtomobilski pnevmatični vzorec

- Delovanje delovnega prenosa, strojna oprema za mehanski menjalnik, vožnja z ročnim menjalnikom, uporabnimi konicami

- PEUGEOT PEUGEOT 206. Nazadnje žarnica PEUGEOT 206 Okvara, popravilo zadnjega žarka Peugeot 206

- Dizelsko gorivo pozimi, aditiv za dizelsko gorivo pozimi, kako izbrati najboljše dizelsko gorivo

- Zima Diesel se ne zažene. Kako začeti z dizelskim dizelcem pozimi, grelno dizelsko ogrevanje pozimi.

- Japonski Bridgestone Pnevmatike, Zimske žrebete Bridgestone Pnevmatike, Bridgestone Pnevmatike Znamka

- Označevanje pnevmatik za osebna vozila, označevanje koles, kako izbrati prave pnevmatike na diskih

- Diesel motor pozimi, zagon dizelskega motorja pozimi, kakšno olje zapolniti dizelski motor pozimi, koristne nasvete

- LED osvetlitev avtomobila, osvetlitev dna avtomobila, osvetlitev nog v avtu, osvetlitev v vratih avtomobila, osvetlitev avtomobila je v redu

- Obnovljene pnevmatike, avtobusne pnevmatike, obnovite zaščito pnevmatik, jih lahko uporabim

- Izberite zimske pnevmatike, ki so zimske pnevmatike, kateri pritisk v zimskih pnevmatikah je treba označiti z zimskimi pnevmatikami, kako izbrati prave zimske pnevmatike, najboljše zimske pnevmatike 2019

- Krmilna tirnica, potrkanje krmilnega stojala, razlogi za potrkanje in popravilo krmilnega stojala

- Chemeless Car Pnevmatike, Set za popravilo pnevmatik brez efadeless, popravilo topovske pnevmatike, to storite sami

- Ruske pnevmatike, ruske pnevmatike zima, ruske vsesezne pnevmatike, voronezh amtel pnevmatike, pnevmatike "matador omsk pnevmatike", Kama-pnevmatike so svetovni avtobus

- Kako odpreti avto brez ključa. Izgubil ključ od avtomobila, kaj storiti, ključ od avtomobila v avtu

- Tihi pnevmatike, tiho zimske pnevmatike, tiho žrebec avtobus, ki jih izbere, pregleda pnevmatike

- Pnevmatike in varnost, varnost avtobusa, zakaj je treba nenehno spremljati avtomobilske pnevmatike

- Pravila varne vožnje avtomobila v dežju in blatu, varna vožnja avtomobila za začetnike

- Pretvornik rje, ki je boljši za avtomobile, rje pretvorniki, da izberejo, kako uporabljati rje pretvornik, strokovnjaki

- Poliranje telesa avtomobila je sami, kako izbrati poliranje pasto, koristne nasvete

- Trajnost motorja, življenjska doba motorja, kako razširiti življenjsko dobo motorja

- Potrkal v avto. Trck pri premikanju avtomobila. Kaj lahko potrka v avto. Kako ugotoviti vzrok Knock.

- ABS Car, kaj je ABS Car, ABS sistem okvare, Diagnostika ABS

- Prehitevanje avtomobila, ko lahko začnete prehitevati avto, pravila prometnih pravil

- Crpalka za gorivo VAZ 2110, PESPEMA VAZ 2110 Bencinske črpalke, VAZ 2110 Naprava za črpalke za gorivo VAZ 2110 Bencinske črpalke,

- Avtomobilske antene za radio, avtomobilsko anteno napravo, avtomobilska antena to storite sami

- Sprednja vzmetenje Kalina, Naprava Sprednje vzmetenje Kalina, potrkanje v sprednjem vzmetenje Kalina, Popravilo sprednjega vzmetenja Kalina

- Blazilnik Olje, najboljši oljni amortizerji, črpalni olje amortizerji, kako pravilno črpati olje

- Motnje sklopke, se dotakne sklopke, povzroči okvaro sklopke, kako odpraviti

Komentarji