Izkušen voznik vedno se počuti, kot se vozilo obnaša na cesti, in na podlagi posameznih funkcij določa, kateri sistem je treba diagnosticirati. Če se nepravilnosti na cesti bolj čutiti v kabini avtomobila, potem zelo verjetno, da je čas, da preverite prekinitve ali njenih posameznih delov. O tem v članku.

Vsebina

- Blazilnik, naprava in namen

- Preverjanje amortizerja, je mogoče razdeliti telo, sodoben avto, preveriti moč blazilnika

- Amortizer ne dela, ki težave ogrozijo avto in voznika, če je amortizer ni

- Preverjanje amortizerja, kako preveriti pomoč blazilnika s svojimi silami, ne da bi razstavljali blazilnik

- Kako preveriti blazilnik na zmogljivosti z napravo s senzorjem za premik

- Test šoka (šok-test) Diagnostika blažilnika

- Ekspresna diagnostika blažilnika

- Preverjanje obremenitve amortizerja amplitude-resonančne poti

- Novi amortizerji, kako preveriti blazilnik na mestu nakupa od prodajalca

- Nasveti prof.

Blazilnik, naprava in namen

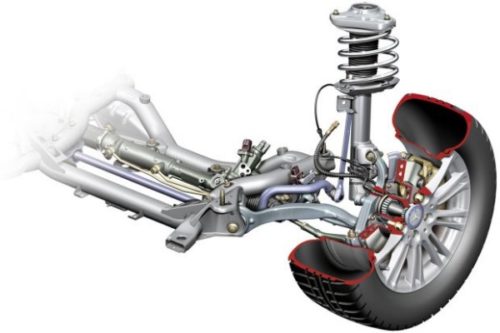

Blazilnik je zasnovan tako, da se ugasne v snosu in šokov, ki pri premikanju prejemajo telo s pomočjo koles. Poleg tega amortizerji omogočajo zanesljiv stik kolesa vozila z nastopom. Torej njihova destinacija ni le udobje, ampak varnost.

Pred tem avtomobili niso bili opremljeni s amortizerji. Njihove funkcije so izvedle vzmeti - je bila izpravljena vibracije zaradi trenja listov, ki so postali drug drugega. Hitrost, s katero se lahko premaknete avtomobile, nenehno rastejo, zaradi katerih so se morajo novi sistemi razvili za varnost in udobje. Tako so regale obstajale v obliki bloka stisnjenih tornih diskov, ki so delali na naslednji način: Vibracije so bile pogašene na račun truda, s katerim so se diski obrnjeni glede na drug drugega. Po določenem času je bilo potrebno opustiti takšen zasnovo, saj so diski hitro nosili in pregreto.

V 20. letih dvajsetega stoletja je bila najdena proizvodnja. Rešitev problema je bila uporaba tekočine, ki ima vibracijo telesa, ki se giblje od enega rezervoarja na drugo pod tlakom.

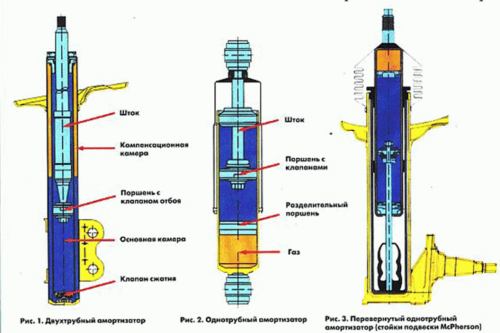

Z njegovo zasnovo lahko stojalo razdelimo na več večjih različic. V strukturi, praviloma, so ene cevi in \u200b\u200bdvo-cevi.

Amortizerji se razlikujejo po vrsti tekočine, ki so napolnjene - plin (z plinsko hidravliko podpod) in hidravlične. Obstajajo preprosto plinski amortizerji, vendar se zelo redko uporabljajo. Plin v njih je pod visokim pritiskom (približno 60 bankomatov).

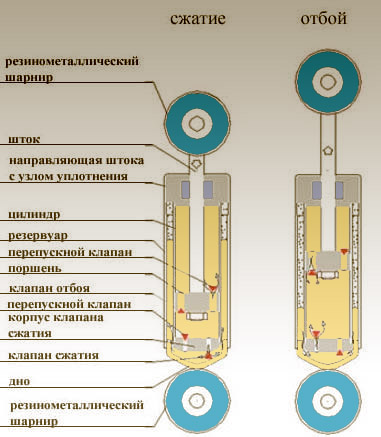

Delovanje blažilnika je hidravlični upor ali odpornost na plin. Olje deluje kot tekočina. Obstajajo sorte stojala, v katerih, poleg olja, odpornost daje stiskanje in tlačno plino.

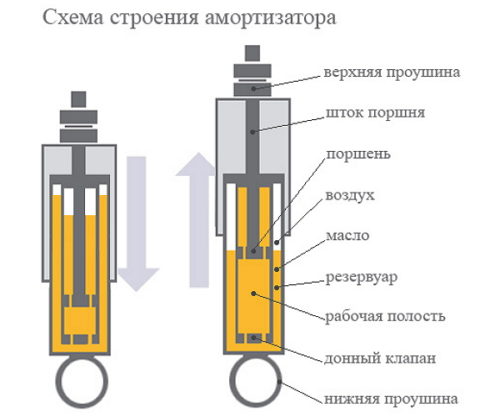

Blazilnik je na voljo na bat in valj. V notranjosti valja, odvisno od modifikacije, so komore - ali s plinom in maslo, ali z zrakom in oljem. V obeh primerih se bat sprehaja znotraj valja, pada in narašča. V drugem primeru se bat upira tlak, ki ga ustvari kompresorna plinska komora. V prvem - bat se premika z odpornostjo, ki se pojavi zaradi pretoka olja s pomočjo ventilov v drugo komoro.

Preverjanje amortizerja, je mogoče razdeliti telo, sodoben avto, preveriti moč blazilnika

Prej, o starih modelih klasičnih avtomobilov s preteklimi vrstami in modeli amortizerjev, se lahko uporabnost stojala zelo preprosto - s pomočjo kup telesa. Kompleksna zasnova sodobne avtomobilske suspenzije ne omogoča vizualno, da bi objektivne ugotovitve o pomoči blazilnika. Vendar pa obstaja veliko drugih učinkovitih metod, ki jih bomo upoštevali spodaj.

Blazilnik ne deluje, kateri težavi ogrožajo avto in voznik, če je blažilnik neuspešen

Glavna okvara amortizerji je sprememba njihovih operativnih parametrov, ki se pojavi zaradi motenj v tesnosti, mehanske poškodbe ali obrabe delovnih elementov (stebla) blazilnika.

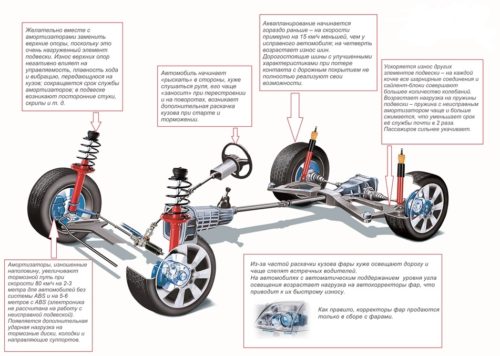

Pomanjkanje amortizerji povzročajo naslednje posledice:

- Kršitev upravljanja avtomobilov. Zapomni si izraz "Nisem se spopadel s kontrolo ...". Nekateri vozniki so včasih presenečeni - no, kako se lahko obvladujem z njim? Pravzaprav je vse preprosto: Ko obrnete vrtenje s hitrostjo, je okvarjeni amortizerji, ki se spontano gibljejo kovinsko kovino.

- Zmanjšanje nosilnosti.

- Zmanjšana stabilnost vozila.

- Povečanje zavorne poti, tveganje "nege" na stran z ekstremnim ali srednjim zaviranjem.

- Pospeševanje obrabe in razčlenitev takih komponent vzmetenja, kot so nosilci regalov, vzmeti, tihih blokov, ležajev s pesti, mazicami, in tako naprej.

- Poslabšanje udobja vožnje.

Preverjanje amortizerja, kako preveriti pomoč blazilnika s svojimi silami, ne da bi razstavljali blazilnik

Zelo pomembno je, da ta metoda lahko preveri samo pomoč amortizerja, namesto njene zmogljivosti. Korespondenca regalov s tehničnimi značilnostmi proizvajalca je ločen pogovor.

Lahko samostojno preverite pomoč amortizerja, ne da bi razstavljali, da lahko le vizualno - diagnosticiranje prisotnosti mehanskih poškodb (t.j.e.e.e.e.e.

Če se uhajanje olja in madeži opazijo na ohišju amortizerja, takoj izrišite zaključek, da so se pečate obrabljene, kar kaže na nastanek blazilnika.

Ljudje je mnenje, da je nafta "megla" v primeru okvare, vendar ni. Ko se držite blazilnik, se ta bučka šteje za običajen pojav.

Pri izvajanju diagnoze blazilnika, po razstavljanju, je treba posebno pozornost nameniti palici - ne bi smela biti jakne, sledi korozije A, zlasti deformacije.

Kako preveriti blazilnik na zmogljivosti z napravo s senzorjem za premik

Ta naprava je "Manual". Pritrjen je na krilu avtomobila, senzor pa je na tleh. Telo je valovilo informacije. Hkrati se v napravo vnesejo tovarniške parametre, ki so hitrost blažilnika. Uspešnost stojala je diagnosticirana v odstotnem razmerju.

Test šoka (šok-test) Diagnostika blažilnika

Test šoka, proizveden na posebnem stojalu. Kolesa osi je treba dvigniti in strmo spustiti. Računalnik registrira koeficient dušenja rack nihanja.

Ekspresna diagnostika blažilnika

Express Diagnostics zagotavlja ostro zaviranje. Izvaja se na stojalu s posebnimi platformami. Hkrati se preveri zavorni sistem. Avto mora ostro vstopiti na ploščad in zavoro. Nihanja telesa avtomobila so fiksne, pa tudi obremenitev senzorjev ploščadi. Čeprav natančnost te metode zapusti veliko želenega.

Preverjanje obremenitve amortizerja amplitude-resonančne poti

Preverjanje amortizerjev AMPLITY-resonant metoda temelji na analizi amplitude (to je vrednosti gibanja) platforme z vozilom, ki je nameščena na njej. Platforma poročajo z nihanji, katerih frekvenca je približno 16 Hz. Ker so podatki oslabljeni, se nihanja pojavi resonanca - povečanje amplitude nihanja, ko je pogostost nihanja platforme in lastne frekvence vzmetenja vozila. Večje vrednosti amplitude dosežejo, slabše ugasne nihanje amortizerja. Nato stojalo primerja rezultate meritev z referenčnimi podatki, po katerih izda zaključek o uspešnosti blazilnika.

Novi amortizerji, kako preveriti blazilnik na mestu nakupa od prodajalca

- Na prostem, vizualni pregled. Preverite označevanje. Ujeti moralo se mora proizvajalčev katalog. Nato morate preveriti blazilnik za prisotnost različnih mehanskih poškodb žlez, ohišja, palice in tako naprej. Preverite navojene povezave. Seveda ne bi smelo biti vključenosti nafte.

- Preverjanje geometrijske skladnosti. Potrebujete čeljust in vladar. Potrebno je preveriti dolžino v stanju Shift, premera palic in premik palice (Orient ali na priporočilo proizvajalca, ali odstopiti od nazivne vrednosti - ± 5 mm).

- Preverjanje zmogljivosti blažilnika. Eno cev se preveri brez predhodne priprave. Morali bi biti stisnjeni in raztegnjeni približno 3-5 krat. Rod se mora nemoteno premikati, brez ostrih kosov in zagozdenja, z enakim napora. Poleg naravnega "predloga", ki je posledica pretoka tekočine v stojalu, ne bi smelo biti tujega škroba in hrupa. Dvojna cev mora biti pripravljena za pred-pripravo - črpalko večkrat (3-5), postavite navpično, po tem, ko ne obrne blazine.

Nasveti prof.

Diagnosticiranje težav, ki so povezane z delom amortizerji, je zelo preprosto - avto se opazno stresa, ko zadene izbokline, sliši se značilno tapkanje. Glavni problem, povezan s prihodom te naprave v slabem, je, da se ta proces pojavi postopoma (izjema je plin in oljni amortizerji, ki so posledica njegove zasnove, lahko takoj ne uspejo). Torej se lahko motorist prilagodi takšnemu vedenju stroja in ne hitite po popravilu. Vendar pa je v tem času obraba pnevmatik in zaviralna pot povečuje, je krmiljenje slabše. Morda vam zdi, da so to majhne stvari, na drugi strani pa lahko v nujnih primerih nepravilno delovanje amortizerji znatno vplivajo na njihov rezultat.

Opozoriti je treba, da je v prometu, ki je opremljen z elektronskimi zavornimi sistemi (EBD, ABS, in tako naprej), okvarjeni amortizerji ne bodo redko privedli do napak navajanja.

Podobni materiali

- Štedilnik 2110, slab topel štedilnik 2110, VAZ 2110 ogrevalnega sistema, Popravilo ogrevalnega sistema VAZ 2110 s svojimi rokami

- VAZ 2114 Štedilnik s hladnim zrakom, štedilnikom 2114, slabim toplim štedilnikom VAZ 2114, naprava in popravilo ogrevanja VAZ 2114 DO-IT-YOUR-PASS, Odstranjevanje štedilnika VAZ 2114

- Kako poddominizirati avto. Kako postaviti Jacka. Vrste priključkov za avtomobile.

- VAZ 2109 varovalka, VAZ 2109 Vaz Block Block Carbubur, VAZ 2109 varovalka Block, Old VAZ 2109 varovalka, VAZ 2109 varovalka, VAZ 2109

- Katalizator izpušnih plinov avtomobila, napačen katalizator, pluse in slabosti katalizatorja, kako spremeniti katalizator za planeeencitel

- Štedilnik piha hladen zrak VAZ 2114, slabo piha peči VAZ 2114, zakaj slabo piha števec VAZ 2114

- Kako izvedeti lastnika avtomobila s številom njegovega avtomobila, preverite avto s številom prometne policije stroj, preverite avto z državo številko avtomobila brezplačno

- Kako izbrati rabljene pnevmatike, koristni nasveti

- Zimska avtomobilska cesta, pritisk v pnevmatikah osebnih avtomobilov pozimi, dobra baterija za avto pozimi, bodisi tople avto v zimskem času

- V zimskem času se avto slabo začenja. Kako narediti avto pozimi, ali se morate ogrevati avto pozimi, koristne nasvete

- Stroji za porabo porabe goriva, najbolj ekonomična poraba avtomobilov

- Pnevmatike blagovne znamke za osebne avtomobile, označevanje avtomobilske pnevmatike, preostale osebni avtomobilski pnevmatike, kako izbrati pnevmatiko na blagovno znamko avtomobila, avtomobilski pnevmatični vzorec

- Delovanje delovnega prenosa, strojna oprema za mehanski menjalnik, vožnja z ročnim menjalnikom, uporabnimi konicami

- PEUGEOT PEUGEOT 206. Nazadnje žarnica PEUGEOT 206 Okvara, popravilo zadnjega žarka Peugeot 206

- Dizelsko gorivo pozimi, aditiv za dizelsko gorivo pozimi, kako izbrati najboljše dizelsko gorivo

- Zima Diesel se ne zažene. Kako začeti z dizelskim dizelcem pozimi, grelno dizelsko ogrevanje pozimi.

- Japonski Bridgestone Pnevmatike, Zimske žrebete Bridgestone Pnevmatike, Bridgestone Pnevmatike Znamka

- Označevanje pnevmatik za osebna vozila, označevanje koles, kako izbrati prave pnevmatike na diskih

- Diesel motor pozimi, zagon dizelskega motorja pozimi, kakšno olje zapolniti dizelski motor pozimi, koristne nasvete

- LED osvetlitev avtomobila, osvetlitev dna avtomobila, osvetlitev nog v avtu, osvetlitev v vratih avtomobila, osvetlitev avtomobila je v redu

- Obnovljene pnevmatike, avtobusne pnevmatike, obnovite zaščito pnevmatik, jih lahko uporabim

- Izberite zimske pnevmatike, ki so zimske pnevmatike, kateri pritisk v zimskih pnevmatikah je treba označiti z zimskimi pnevmatikami, kako izbrati prave zimske pnevmatike, najboljše zimske pnevmatike 2019

- Krmilna tirnica, potrkanje krmilnega stojala, razlogi za potrkanje in popravilo krmilnega stojala

- Chemeless Car Pnevmatike, Set za popravilo pnevmatik brez efadeless, popravilo topovske pnevmatike, to storite sami

- Ruske pnevmatike, ruske pnevmatike zima, ruske vsesezne pnevmatike, voronezh amtel pnevmatike, pnevmatike "matador omsk pnevmatike", Kama-pnevmatike so svetovni avtobus

- Kako odpreti avto brez ključa. Izgubil ključ od avtomobila, kaj storiti, ključ od avtomobila v avtu

- Tihi pnevmatike, tiho zimske pnevmatike, tiho žrebec avtobus, ki jih izbere, pregleda pnevmatike

- Pnevmatike in varnost, varnost avtobusa, zakaj je treba nenehno spremljati avtomobilske pnevmatike

- Pravila varne vožnje avtomobila v dežju in blatu, varna vožnja avtomobila za začetnike

- Pretvornik rje, ki je boljši za avtomobile, rje pretvorniki, da izberejo, kako uporabljati rje pretvornik, strokovnjaki

- Poliranje telesa avtomobila je sami, kako izbrati poliranje pasto, koristne nasvete

- Trajnost motorja, življenjska doba motorja, kako razširiti življenjsko dobo motorja

- Potrkal v avto. Trck pri premikanju avtomobila. Kaj lahko potrka v avto. Kako ugotoviti vzrok Knock.

- ABS Car, kaj je ABS Car, ABS sistem okvare, Diagnostika ABS

- Prehitevanje avtomobila, ko lahko začnete prehitevati avto, pravila prometnih pravil

- Crpalka za gorivo VAZ 2110, PESPEMA VAZ 2110 Bencinske črpalke, VAZ 2110 Naprava za črpalke za gorivo VAZ 2110 Bencinske črpalke,

- Avtomobilske antene za radio, avtomobilsko anteno napravo, avtomobilska antena to storite sami

- Sprednja vzmetenje Kalina, Naprava Sprednje vzmetenje Kalina, potrkanje v sprednjem vzmetenje Kalina, Popravilo sprednjega vzmetenja Kalina

- Blazilnik Olje, najboljši oljni amortizerji, črpalni olje amortizerji, kako pravilno črpati olje

- Motnje sklopke, se dotakne sklopke, povzroči okvaro sklopke, kako odpraviti

Komentarji