Do sedaj, je sistem vbrizgavanja aktivno uporablja na bencin in dizel motorjem. Treba je omeniti, da je za vsako spremembo motorja, podoben sistem bistveno se bo razlikovala. O tem v članku.

Vsebina

- Injekcijski sistem, namen kot le bencinski vbrizgavanjem sistema razlikuje od sistema za vbrizgavanje dizelskega

- Sistem vbrizgavanja bencina, vbrizg goriva Sistem za bencinske motorje

- Injection sistemi bencinskih motorjev, vrst sistemov za vbrizg goriva, prednosti in slabosti posamezne vrste bencinskih motorjev sistemov za vbrizgavanje

- Dizelski motorji vbrizgavanje sistemi, vrste sistemov, prednosti in slabosti posamezne vrste sistemov za vbrizgavanje dizelskega goriva

- sklepi

Injekcijski sistem, namen kot le bencinski vbrizgavanjem sistema razlikuje od sistema za vbrizgavanje dizelskega

Glavni namen sistema za vbrizgavanje (drugo ime je sistem za vbrizgavanje) - zagotoviti pravočasno dobavo goriva v delovnih valjev motorja.

V bencinske motorje, postopek vbrizgavanja podpira nastanek zmesi zraka in goriva, nakar se njegova kontakta izvedena z iskro. Pri dizelskih motorjih, je dovod goriva izvedemo pod visokim tlakom - en del gorljive mešanice kombiniramo s stisnjenim zrakom in skoraj v trenutku samo-razmnoženi.

Sistem vbrizgavanja bencina, vbrizg goriva Sistem za bencinske motorje

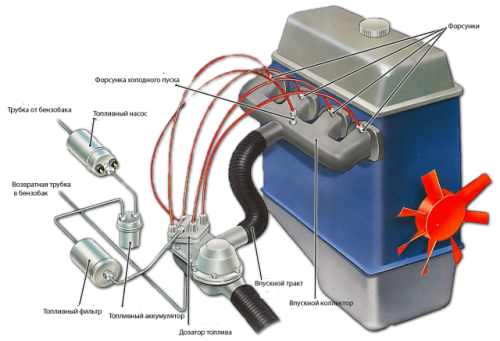

vbrizgavanje goriva sistem je sestavni del sistema TC goriva. Glavno delovno telo po kateremkoli sistema vbrizgavanja je šoba. Odvisno od načina tvorbe zmesi zraka in goriva, kot so sistemi neposrednim vbrizgavanjem, porazdeljenih injiciranje in osrednji injekcijo. Sistemi distribuirane in centralnega injiciranje - vbrizgavanja, ki je injekcija v njih izvaja v sesalni cevi, ne doseže zgorevalno komoro.

Injection sistemi bencinski motorji imajo lahko elektronsko ali mehansko kontrolo. Elektronski nadzor injekcija velja najpopolnejša, ki omogoča bistveno manjšo porabo goriva in zmanjšanje škodljivih emisij v ozračje.

Za vbrizgavanje goriva v sistemu poteka impulz (diskretna) ali kontinuirno. Z vidika varčevanja perspektive, se šteje za vbrizg goriva, ki se z vsemi sodobnimi sistemi uporabljajo.

V motorja, se sistem vbrizgavanja običajno povezan s sistemom za vžig in ustvari kombinirana vžig in sistemom za vbrizgavanje (npr Fenix, Motronic sistem). Sistem za nadzor motorja omogoča usklajeno delovanje sistema.

Injection sistemi bencinskih motorjev, vrst sistemov za vbrizg goriva, prednosti in slabosti posamezne vrste bencinskih motorjev sistemov za vbrizgavanje

V bencinske motorje se uporabljajo sistemi za dovod kot goriva - neposredno vbrizgavanje, kombinirano injekcijo, razdeli injekcija (večtočkovno), centralno injekcija (monovosprysk).

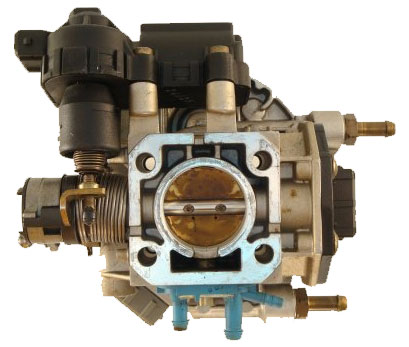

Srednja injekcijo. dovod goriva v tem sistemu je izdelan s pomočjo injektorja goriva, ki se nahaja v sesalnem kolektorju. In ker je šoba je samo eden, se ta sistem imenuje drugega monofry.

Danes je centralni sistem za vbrizgavanje izgubila svoj pomen, tako da niso na voljo v novih modelov avtomobila, vendar je v nekaterih starih vozil, lahko še vedno mogoče najti.

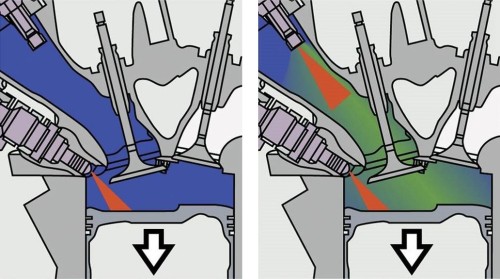

Prednosti monofry so zanesljivi in \u200b\u200bpreprostost. Z slabosti tega sistema, ki vključuje veliko porabo goriva in nizko motorja ekologijo. Distributed injekcijo. V večtočkovni sistem za vbrizgavanje, ki je ločen dovod goriva predvidena vsak valj, ki je opremljen z vstopom posameznega goriva. TV, s tem se pojavlja samo v sesalnem kolektorju.

Do danes je večina bencinski motorji opremljeni s sistemom oskrbe distribuirane goriva. Prednosti takšnega sistema so poraba optimalna goriva, visoka prijaznost do okolja, porabi optimalno potreba po gorivu.

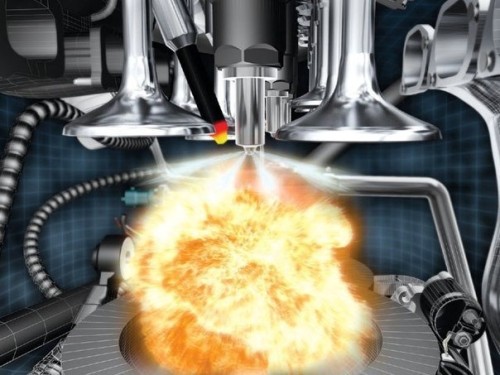

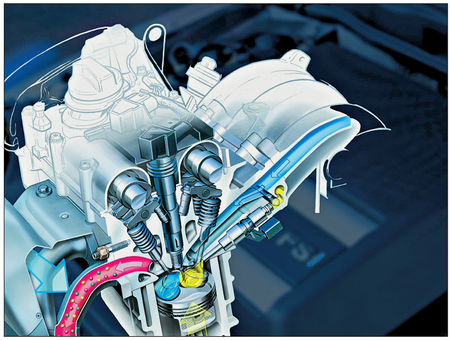

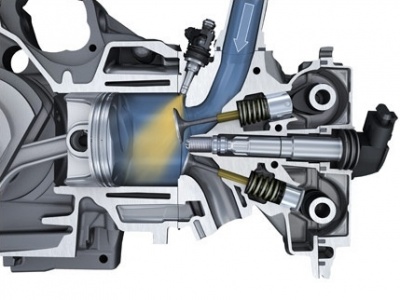

Neposredno vbrizgavanje. Eden od najbolj naprednih in popolnih sistemov za vbrizg. Princip delovanja tega sistema temelji na ravne (direktno) oskrbo z gorivom v zgorevalni komori.

Neposredna sistem za dovajanje goriva omogoča, da dobimo sestavek kakovostno goriva v vseh fazah operacije motorja izboljšati proces zgorevanja goriva sklop, povečati obratovalno moč motorja in zmanjša stopnjo izpušnih plinov.

Slabosti tega sistema vbrizgavanja so precej zapletene konstrukcije in večje zahteve glede kakovosti goriva.

Kombinirano injekcijo. Oba sistema sta združena v sistemu te vrste - porazdeljeno in neposredni vbrizg. Praviloma se uporablja za zmanjšanje emisij strupenih sestavin in izrabljenih plinov, s katerimi je mogoče doseči visoke kazalnike motornih ekologija.

Dizelski motorji vbrizgavanje sistemi, vrste sistemov, prednosti in slabosti posamezne vrste sistemov za vbrizgavanje dizelskega goriva

Naslednji vbrizgalni sistemi se uporabljajo na modernih dizelskih motorjih - sistem Common Rail, sistem črpalka-šoba, sistem s črpalko za gorivo distribucijo ali vrstice z visokim tlakom (TNVD).

Najbolj priljubljena in postopno so črpalke-šobe in Common Rail. TNVD je osrednja sestavina vsakega sistema za gorivo dizelskih motorjev.

Dobava zmesi gorivo v dizelskih motorjih se lahko izvede iz predhodne komore ali neposredno v zgorevalni prostor.

Trenutno je prednost sistema neposrednega vbrizgavanja, ki ima povečano stopnjo hrupa in manj nemoteno delovanje motorja v primerjavi z oskrbo na predhodno komoro, pa je zagotovljena bolj pomemben kazalec - učinkovitost.

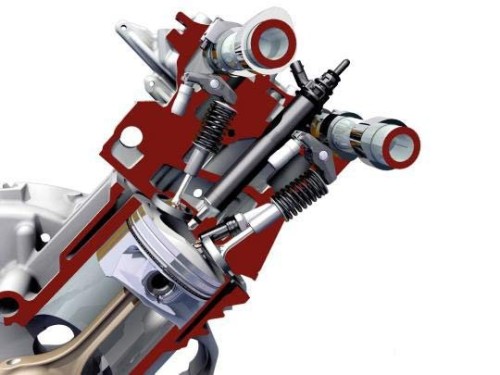

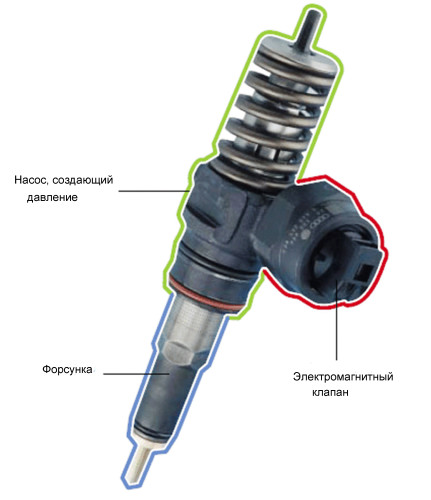

Sistem črpalka-šoba. Ta sistem se uporablja za krmo, kot tudi injiciranju gorljive mešanice pod visokotlačno črpalko šobami. Glavna značilnost tega sistema - v eni napravi, sta dve funkciji kombinirani - injekcijo in ustvarjanje tlaka.

Konstruktivno Pomanjkljivost tega sistema - je črpalka opremljena s konstantno vožnjo z motornim odmične gredi (ne invalide), ki lahko vodi do hitre obrabe sistema. Kot rezultat, proizvajalci vedno raje common rail sisteme.

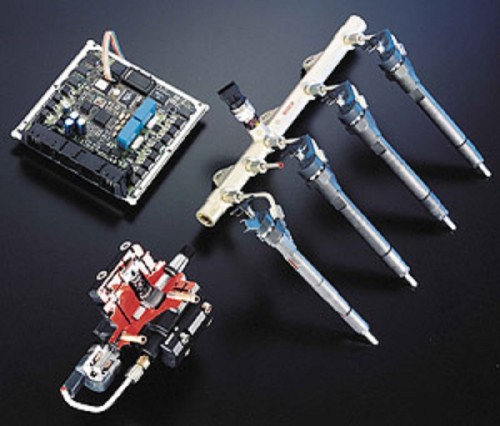

Injiciranje baterije (skupna tirnica). Napredno zasnova gorljivih mešanic za različne dizelske motorje. V takem sistemu se gorivo hrani iz rampe do injektorjev goriva, ki se imenuje tudi visokotlačna baterija, zaradi katere je sistem oblikoval drugo ime - vbrizgavanje baterije.

Sistem Common Rail zagotavlja v naslednjih fazah injiciranje - predhodnih, glavnih in dodatnih. Zaradi tega je mogoče zmanjšati vibracije in hrup motorja, da bi postopek za učinkovitejši postopek samozavestnega vžiga, zmanjšanje škodljivih emisij.

sklepi

Za upravljanje sistemov injiciranja na dizelm je predvidena prisotnost elektronskih in mehanskih naprav. Mehanski sistemi omogočajo nadzor delovnega tlaka, trenutka in prostornine vbrizgavanja goriva. Elektronski sistemi zagotavljajo učinkovitejši nadzor dizelskih motorjev na splošno.

Podobni materiali

- Štedilnik 2110, slab topel štedilnik 2110, VAZ 2110 ogrevalnega sistema, Popravilo ogrevalnega sistema VAZ 2110 s svojimi rokami

- VAZ 2114 Štedilnik s hladnim zrakom, štedilnikom 2114, slabim toplim štedilnikom VAZ 2114, naprava in popravilo ogrevanja VAZ 2114 DO-IT-YOUR-PASS, Odstranjevanje štedilnika VAZ 2114

- Kako poddominizirati avto. Kako postaviti Jacka. Vrste priključkov za avtomobile.

- VAZ 2109 varovalka, VAZ 2109 Vaz Block Block Carbubur, VAZ 2109 varovalka Block, Old VAZ 2109 varovalka, VAZ 2109 varovalka, VAZ 2109

- Katalizator izpušnih plinov avtomobila, napačen katalizator, pluse in slabosti katalizatorja, kako spremeniti katalizator za planeeencitel

- Štedilnik piha hladen zrak VAZ 2114, slabo piha peči VAZ 2114, zakaj slabo piha števec VAZ 2114

- Kako izvedeti lastnika avtomobila s številom njegovega avtomobila, preverite avto s številom prometne policije stroj, preverite avto z državo številko avtomobila brezplačno

- Kako izbrati rabljene pnevmatike, koristni nasveti

- Zimska avtomobilska cesta, pritisk v pnevmatikah osebnih avtomobilov pozimi, dobra baterija za avto pozimi, bodisi tople avto v zimskem času

- V zimskem času se avto slabo začenja. Kako narediti avto pozimi, ali se morate ogrevati avto pozimi, koristne nasvete

- Stroji za porabo porabe goriva, najbolj ekonomična poraba avtomobilov

- Pnevmatike blagovne znamke za osebne avtomobile, označevanje avtomobilske pnevmatike, preostale osebni avtomobilski pnevmatike, kako izbrati pnevmatiko na blagovno znamko avtomobila, avtomobilski pnevmatični vzorec

- Delovanje delovnega prenosa, strojna oprema za mehanski menjalnik, vožnja z ročnim menjalnikom, uporabnimi konicami

- PEUGEOT PEUGEOT 206. Nazadnje žarnica PEUGEOT 206 Okvara, popravilo zadnjega žarka Peugeot 206

- Dizelsko gorivo pozimi, aditiv za dizelsko gorivo pozimi, kako izbrati najboljše dizelsko gorivo

- Zima Diesel se ne zažene. Kako začeti z dizelskim dizelcem pozimi, grelno dizelsko ogrevanje pozimi.

- Japonski Bridgestone Pnevmatike, Zimske žrebete Bridgestone Pnevmatike, Bridgestone Pnevmatike Znamka

- Označevanje pnevmatik za osebna vozila, označevanje koles, kako izbrati prave pnevmatike na diskih

- Diesel motor pozimi, zagon dizelskega motorja pozimi, kakšno olje zapolniti dizelski motor pozimi, koristne nasvete

- LED osvetlitev avtomobila, osvetlitev dna avtomobila, osvetlitev nog v avtu, osvetlitev v vratih avtomobila, osvetlitev avtomobila je v redu

- Obnovljene pnevmatike, avtobusne pnevmatike, obnovite zaščito pnevmatik, jih lahko uporabim

- Izberite zimske pnevmatike, ki so zimske pnevmatike, kateri pritisk v zimskih pnevmatikah je treba označiti z zimskimi pnevmatikami, kako izbrati prave zimske pnevmatike, najboljše zimske pnevmatike 2019

- Krmilna tirnica, potrkanje krmilnega stojala, razlogi za potrkanje in popravilo krmilnega stojala

- Chemeless Car Pnevmatike, Set za popravilo pnevmatik brez efadeless, popravilo topovske pnevmatike, to storite sami

- Ruske pnevmatike, ruske pnevmatike zima, ruske vsesezne pnevmatike, voronezh amtel pnevmatike, pnevmatike "matador omsk pnevmatike", Kama-pnevmatike so svetovni avtobus

- Kako odpreti avto brez ključa. Izgubil ključ od avtomobila, kaj storiti, ključ od avtomobila v avtu

- Tihi pnevmatike, tiho zimske pnevmatike, tiho žrebec avtobus, ki jih izbere, pregleda pnevmatike

- Pnevmatike in varnost, varnost avtobusa, zakaj je treba nenehno spremljati avtomobilske pnevmatike

- Pravila varne vožnje avtomobila v dežju in blatu, varna vožnja avtomobila za začetnike

- Pretvornik rje, ki je boljši za avtomobile, rje pretvorniki, da izberejo, kako uporabljati rje pretvornik, strokovnjaki

- Poliranje telesa avtomobila je sami, kako izbrati poliranje pasto, koristne nasvete

- Trajnost motorja, življenjska doba motorja, kako razširiti življenjsko dobo motorja

- Potrkal v avto. Knock pri premikanju avtomobila. Kaj lahko potrka v avto. Kako ugotoviti vzrok Knock.

- ABS Car, kaj je ABS Car, ABS sistem okvare, Diagnostika ABS

- Prehitevanje avtomobila, ko lahko začnete prehitevati avto, pravila prometnih pravil

- Crpalka za gorivo VAZ 2110, PESPEMA VAZ 2110 Bencinske črpalke, VAZ 2110 Naprava za črpalke za gorivo VAZ 2110 Bencinske črpalke,

- Avtomobilske antene za radio, avtomobilsko anteno napravo, avtomobilska antena to storite sami

- Sprednja vzmetenje Kalina, Naprava Sprednje vzmetenje Kalina, potrkanje v sprednjem vzmetenje Kalina, Popravilo sprednjega vzmetenja Kalina

- Blazilnik Olje, najboljši oljni amortizerji, črpalni olje amortizerji, kako pravilno črpati olje

- Motnje sklopke, se dotakne sklopke, povzroči okvaro sklopke, kako odpraviti

Komentarji