La boquilla automotriz es un dispositivo que es responsable de la pulverización directa de combustible dentro de la cámara de combustión. Hasta la fecha, hay varias modificaciones de este dispositivo. Sobre esto más allá en el artículo.

Contenido

- Sistema de inyección de combustible, desde donde consiste el sistema de inyección.

- Inyección directa o para lo que necesita boquillas en el motor.

- Tipos de boquillas y su propósito.

- Boquilla electromagnética, dispositivo y principio de trabajo.

- Boquilla de gasolina en el contexto.

- Boquilla Diesel, Boquillas De Motor Diesel, Dispositivo y Principio de Operación

- Piezoforun, dispositivo

- Piezohoroforsunk, principio de trabajo

- Piezohoroforsunk, dignidad

Sistema de inyección de combustible, desde donde consiste el sistema de inyección.

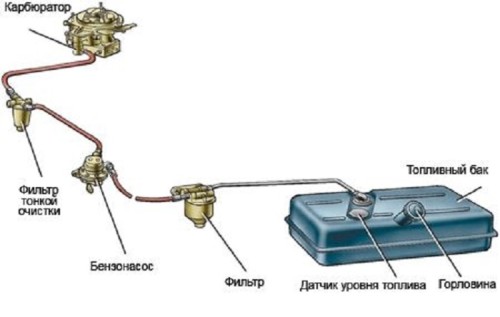

El sistema de combustible consta de tales elementos:

- Bombillas superiores.

- Depósito de combustible.

- Bomba de combustible.

- Filtros de combustible.

- Dispositivo para mezclar aire y combustible.

- Control de presión de combustible.

- Colector de admisión.

- Filtro de aire.

- Sensores.

- El silenciador del ruido de los gases de escape.

Dependiendo del dispositivo utilizado para mezclar aire y combustible, hay tres tipos de sistemas de combustible:

- Sistema de combustible recargable: utilizado en motores diesel.

- Sistema de combustible de carburador: utilizado en motores de carburador.

- Sistema de combustible inyector: utilizado en motores de gasolina. En este caso, para mezclar aire y combustible es responsable de la boquilla.

Inyección directa o para lo que necesita boquillas en el motor.

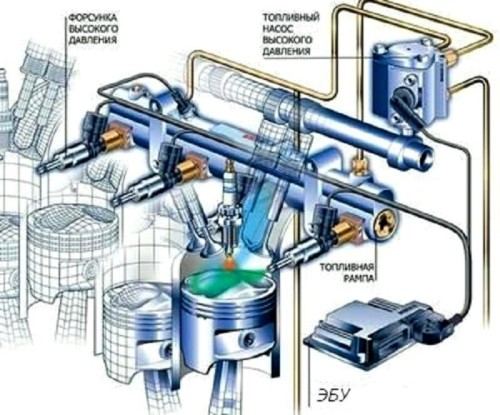

La inyección directa es la mezcla de la inyección de combustible distribuida, donde se inyecta directamente el combustible en los cilindros. La boquilla es el componente de unión principal entre la bomba de combustible y el motor. El propósito principal de las boquillas:

- Asegurar la dosis correcta del combustible suministrado al motor.

- Asegurando el chorro correcto (cantidad, presión, ángulo) de la mezcla.

Tipos de boquillas y su propósito.

Boquilla electromagnética, dispositivo y principio de trabajo.

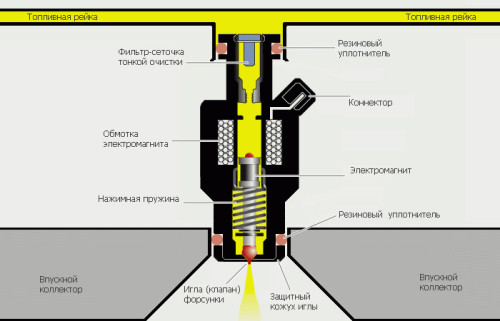

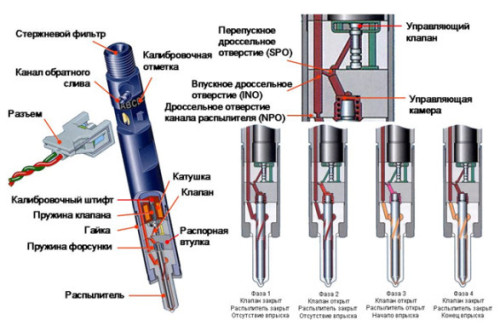

Dichos dispositivos electromagnéticos se utilizan, como regla general, en motores de gasolina, incluso con inyección directa. Este tipo de equipo tiene un diseño bastante simple que consiste en:

- Boquilla de la boquilla.

- Aguja.

- Sellar en el caso.

- La carcasa de la boquilla.

- Ancla de la electromagnet.

- Primavera especial.

- Desinversión electromagnética de excitación.

- Conector eléctrico.

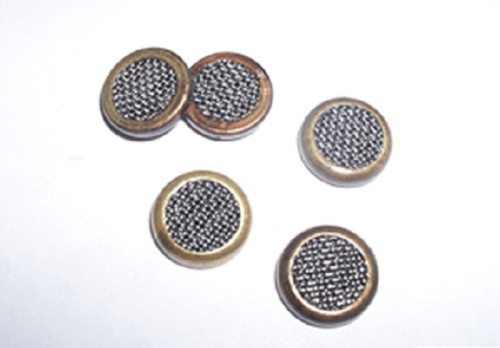

- Filtro de malla.

La boquilla realiza salpicaduras de combustible. Es de la calidad de la operación de este componente depende de la operación de todo el dispositivo. El filtro de malla filtra el combustible que pasa a través de la boquilla.

ECU, correspondiente al algoritmo establecido previamente, en el momento requerido garantiza el suministro de voltaje al devanado de la excitación de la válvula. En el proceso de esto, se produce un campo electromagnético, superando la fuerza de resorte, después de lo cual retrasa un anclaje con una aguja, que libera la boquilla. Después de todo esto es la inyección de combustible. Cuando el voltaje desaparece, la aguja de la boquilla vuelve a la silla usando la primavera.

Boquilla de gasolina en el contexto.

- Filtro de malla.

- Boquilla de la boquilla.

- Sello.

- Boquilla de aguja.

- La carcasa de la boquilla.

- Electromagnet de anclaje.

- Cierre de arnés.

- Primavera.

- Conector eléctrico.

Boquilla Diesel, Boquillas De Motor Diesel, Dispositivo y Principio de Operación

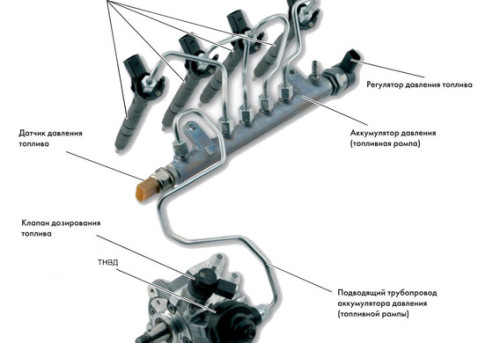

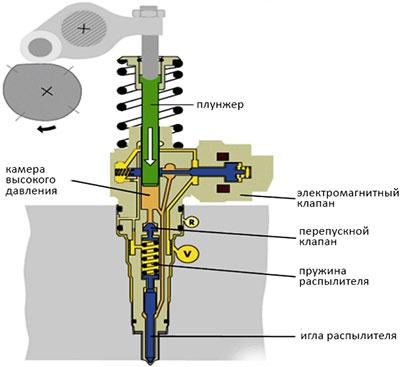

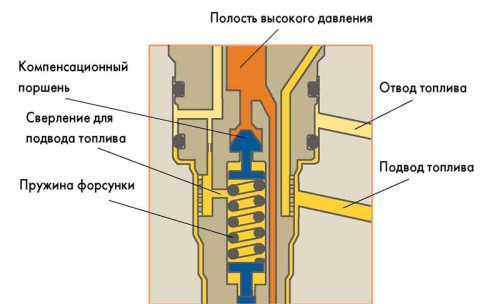

En los motores diesel, incluidos los equipados con el sistema de inyección "Riel común", se utilizan boquillas electrohidráulicas. El diseño de este dispositivo incluye una válvula electromagnética, una cámara de control, así como un estrangulamiento de desagüe y admisión.

El principio de operación de dicho equipo se basa en el uso de la presión del combustible durante la inyección, así como, después de su terminación. En la posición inicial, la válvula solenoide está completamente cerrada y desenergizada, la aguja del dispositivo se presiona en la silla de montar con una presión sobre el pistón de combustible en la cámara de control. La inyección de combustible en esta posición no se realiza. Vale la pena señalar que la presión del combustible en la aguja, en esta situación, menos presión, que se produce en el pistón, como resultado de la diferencia en las áreas de contacto.

Después del comando de la ECU, se activa la válvula solenoide y se abre el acelerador de drenaje. Combustible, que se encuentra en la cámara de control, mientras que fluye a través del acelerador en la carretera de desagüe. El estrangulador de admisión es un obstáculo para la nivelación más rápida de las presiones en la línea de entrada y la cámara de control. Sin embargo, gradualmente existe una disminución de la presión sobre el pistón, la presión del combustible ejercida en la aguja no cambia, lo que resulta en elevar la aguja y la inyección de combustible.

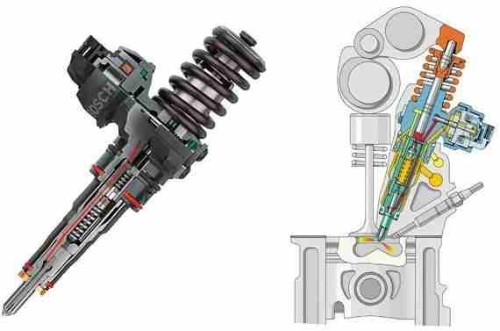

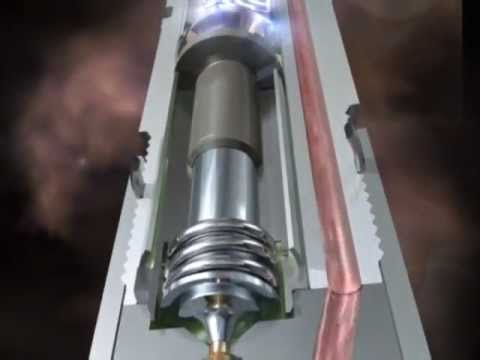

Piezoforun, dispositivo

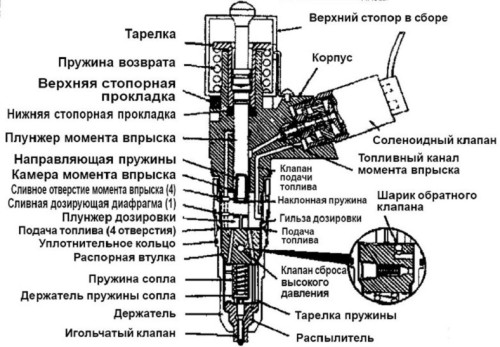

El diseño de la piezoquimificación incluye tales componentes:

- Canal de suministro de combustible.

- Conector de boquilla eléctrica.

- Microfiltro.

- Cría de canales.

- Piezoelemento.

- Empuje de pistón.

- Pistón de la válvula.

- Válvula de primavera.

- Válvula de conmutación.

- Bloque de estrangulamiento.

- Pulverizador de aguja de primavera.

- Lavadora ignífuga.

- La aguja del pulverizador.

Piezohoroforsunk, principio de trabajo

El funcionamiento de la válvula de control de la boquilla se basa en un conocido efecto piezoeléctrico utilizado, por ejemplo, en los encendedores de gas. El dedo del hombre presiona un botón que deforma el componente de trabajo desde el dieléctrico. Como resultado, la carga utilizada para inflamar el gas.

En boquillas piezoeléctricas, t. N. Efecto piezoeléctrico inverso. El voltaje se alimenta a la dieléctrica, que contribuye a la deformación del material. La barra de la válvula está conectada a ella, que es capaz de escalar si la corriente se alimenta a la boquilla.

Piezohoroforsunk, dignidad

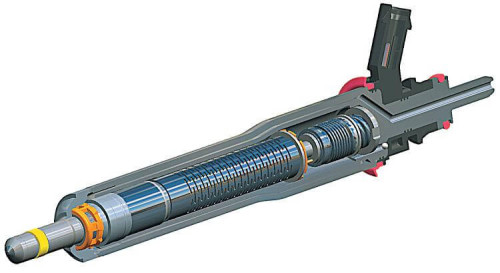

- Boquillas de alta eficiencia.

- Reducción de ruido en el proceso de operación del motor.

- La capacidad de cambiar la presión de inyección.

- Aumenta la velocidad de la boquilla.

Materiales relacionados

- Estufa 2110, mala cálida cálida 2110, sistema de calefacción VAZ 2110, reparando el sistema de calefacción VAZ 2110 con sus propias manos.

- VAZ 2114 estufa sopla con aire frío, estufa 2114, estufa de mala cálida VAZ 2114, dispositivo y reparación de calefacción VAZ 2114 Hágalo usted mismo, eliminando la estufa VAZ 2114

- Cómo subdominizar el coche. Cómo poner un gato. Tipos de tomas para automóviles.

- VAZ 2109 Bloque de fusibles, VAZ 2109 Bloque de fusibles Carburador, VAZ 2109 Inyector de bloques de fusibles, VAZ 2109 Bloque de fusibles, VAZ 2109 Bloque de fusibles, Bloque de fusibles VAZ 2109

- Catalizador de gases de escape del coche, catalizador defectuoso, ventajas y contras del catalizador, cómo cambiar el catalizador en el avión

- Estufa soplando aire frío VAZ 2114, mal soplando la estufa Vaz 2114, ¿por qué soplando mal la estufa VAZ 2114?

- ¿Cómo descubrir al propietario del automóvil por el número de su automóvil, verifique el automóvil por el número de la máquina de policía de tráfico, consulte el automóvil por el número de estado del automóvil gratis

- Cómo elegir neumáticos usados, consejos útiles

- Carretera de invierno, presión en neumáticos de coche de pasajeros en invierno, buena batería para el automóvil en invierno, ya sea para calentar el auto en invierno.

- En invierno, el coche está mal empezado. Cómo hacer un auto en invierno, ¿necesita calentar el auto en invierno, consejos útiles?

- Máquinas de consumo de combustible económico, el consumo más económico del automóvil.

- Neumáticos Marcas para automóviles de pasajeros, etiquetado de etiquetado de neumáticos de automóviles, protector de neumáticos de coche de pasajeros residuales, cómo elegir un neumático en una marca de automóviles, patrón de la banda de rodadura del neumático del coche

- Operación de transmisión de trabajo, trabajo de embrague de caja de cambios mecánica, conducción con caja de cambios manual, consejos útiles

- Peugeot 206 sedán de haz trasero, dispositivo de haz trasero PEUGEOT 206. PEUGEOT TRASERO PEUGEOT 206 Mal funcionamiento, reparación de la viga trasera Peugeot 206

- Combustible diesel en invierno, aditivo para combustible diesel en invierno, cómo elegir el mejor combustible diesel

- El invierno diesel no comienza. Cómo comenzar Diesel en invierno, calefacción diesel en invierno.

- Neumáticos de bridgestone japoneses, neumáticos de bridgestone tachonados de invierno, neumáticos bridgestone de marca

- Decodificación de marcado de neumáticos para automóviles de pasajeros, llantas de etiquetado, cómo elegir los neumáticos adecuados en los discos

- Motor diesel en invierno, lanzamiento del motor diesel en invierno, qué aceite para llenar un motor diesel en invierno, consejos útiles

- Luz de retroiluminación LED del automóvil, la luz de fondo de la parte inferior del automóvil, la luz de fondo de las piernas en el automóvil, la luz de fondo en la puerta del automóvil, la luz de fondo del automóvil está bien.

- Neumáticos recuperados, neumáticos de bus, protector de neumáticos restaurado, ¿puedo usarlos?

- Elija neumáticos de invierno, que es un neumáticos de invierno, que la presión en los neumáticos de invierno debe estar marcada con neumáticos de invierno, cómo elegir los neumáticos de invierno adecuados, los mejores neumáticos de invierno 2019

- Dirección de ferrocarril, golpe de rack de dirección, razones para el golpe y la reparación del bastidor de dirección lo hace usted mismo

- Los neumáticos de automóviles sin intermediarios, un conjunto para la reparación de neumáticos sin cámara, la reparación del neumático sin cañón, hágalo usted mismo.

- Neumáticos rusos, neumáticos rusos, neumáticos rusos, neumáticos de toda la temporada, neumáticos Voronezh AMTEL, Neumáticos "Matador Omsk Tire", KAMA-LIRIONS son autobuses de clase mundial

- Cómo abrir un auto sin clave. Perdí la llave del auto que hacer, la llave del auto dentro del auto.

- Neumáticos silenciosos, neumáticos de invierno tranquilos, autobús con tachuelas tranquilos, que los neumáticos para elegir, los neumáticos de resumen

- Neumáticos y seguridad, seguridad del autobús, por qué es necesario monitorear constantemente los neumáticos de automóviles.

- Reglas de conducción segura del automóvil en la lluvia y aguanieve, conducción segura del automóvil para principiantes.

- Convertidor de óxido que es mejor para los autos, los convertidores de óxido para elegir cómo usar el transductor de óxido, los profesionales

- Pulir el cuerpo del auto hacerlo usted mismo, cómo elegir una pasta de pulido, consejos útiles

- Durabilidad del motor, vida del motor, cómo extender la vida del motor.

- Llamar al coche. Golpear al mover el coche. ¿Qué puede llamar al coche? Cómo determinar la causa del golpe.

- ABS Car, ¿qué es el auto de ABS, el mal funcionamiento del sistema ABS, los diagnósticos de ABS?

- Adelantar un automóvil cuando puede comenzar a adelantar un automóvil, reglas de reglas de tráfico

- Bomba de combustible VAZ 2110, VAZ 2110 Esquema de gasolina, dispositivo de bomba de combustible VAZ 2110, reparación de gasolina VAZ 2110,

- Antenas automotrices para radio, dispositivo de antena automotriz, antena de automóvil.

- Suspensión delantera Kalina, dispositivo de suspensión delantero Kalina, golpe en suspensión delantera Kalina, reparación de suspensión delantera Kalina

- Aceite de amortiguador, los mejores amortiguadores de aceite, bombear los amortiguadores de aceite, cómo bombear correctamente el amortiguador de aceite

- El mal funcionamiento del embrague, toca el embrague, causa un mal funcionamiento del embrague, cómo eliminar

Comentarios