El cinturón del mecanismo de distribución de gas es un atributo indispensable para la mayoría de los vehículos modernos, incluso para el automóvil Chevrolet Lacetti. A pesar de la simplicidad excepcional, este es un detalle bastante importante para el motor de combustión interna. Sustitución de la correa de distribución en Chevrolet Lacetti - el evento es bastante tiempo, pero es totalmente sencilla, si se actúa exactamente debajo de las instrucciones proporcionadas.

Contenido

- La correa de distribución, lo que lo hacen las tareas de la correa de distribución

- La correa de distribución, ya que funciona y de qué material

- ¿Con qué frecuencia cambiar la correa de distribución

- ¿Cuánto hay que cambiar la correa de distribución, lo que los signos a hablar de la necesidad de reemplazar la correa de distribución

- Se rompió la correa de distribución, que conduce un desglose tales

- correa de distribución, por qué el cambio de la correa es mejor que hacer en el kit

- Herramientas, Accesorios, Consumibles

- Técnica de seguridad

- Sustitución de la correa de distribución Chevrolet Lacetti, paso a paso de trabajo

- Consejos Profi, cómo controlar la tensión de la correa de distribución

La correa de distribución, lo que lo hacen las tareas de la correa de distribución

La tarea es que el árbol de levas gira a una velocidad, exactamente la mitad de la facturación idéntica cigüeñal. A la mitad de hace un siglo, la transmisión por cadena GRM se utiliza en la industria del automóvil, y todos los intentos de adaptar el cinturón para esto se malentendido. Pasó mucho tiempo antes de la transmisión por correa comenzó a dominar. Sin embargo, tiene varias ventajas significativas - la simplificación del diseño, bajo nivel de ruido y una disminución en la masa de la unidad de potencia.

Hoy en día, los fabricantes prefieren instalar unidades de cinturón en sus autos. Pero es imposible decir inequívocamente que la cadena es peor que el cinturón. La transmisión de la cadena también tiene su ventaja: durabilidad, correlacionada con la duración del motor en sí. Por lo tanto, incluso en nuestro tiempo, algunas compañías manufactureras detienen su elección en el mecanismo de la cadena. Además, tales motores generalmente están equipados con tensores automáticos. La vida útil del cinturón ordinario rara vez supera los 60 mil kilómetros, y la simplicidad del diseño implica la necesidad de un servicio permanente: pull-up, reemplazo, control sobre el estado de la correa.

La correa de distribución, ya que funciona y de qué material

Para que la correa de distribución funcione de manera confiable, se deben observar las siguientes condiciones: el estado óptimo de las poleas y los rodillos a lo largo de los cuales se mueve la correa, la tensión correcta de la correa, su protección absoluta contra el aceite y la suciedad. El diseño de la correa es bastante simple y algo se asemeja a un neumático de coche.

Por lo tanto, la mayoría de las empresas que se especializan en la producción de neumáticos también producen cinturones. La base de la correa de distribución: cable: el plexo de hilos duraderos de fibra de vidrio. Los cables interior son los dientes de los materiales resistentes al desgaste (como regla, nylon), y fuera, protege la capa de caucho, cuyo espesor es de aproximadamente cinco milímetros. El diseño de los cinturones es bastante diverso. Puede diferir en el ancho de la correa, el número y el paso de los dientes, así como su perfil (hay alrededor de veinte tipos de perfiles de dientes).

¿Con qué frecuencia cambia la correa dentada?

El reemplazo de la correa dentada en Chevrolet Lacetti, de acuerdo con las regulaciones de mantenimiento, es necesario realizar cada 60,000 kilómetros de kilómetros. Sin embargo, la mayoría de los especialistas recomiendan reducir el cambio en el período de reemplazo debido a condiciones de funcionamiento complejas. En cuanto a la verificación del estado del cinturón, entonces, en el automóvil, Chevrolet Lacetta, se debe realizar cada 30 mil kilómetros.

¿Cuánto cambiará la correa dentada, qué señales hablan sobre la necesidad de reemplazar la correa dentada?

- Vistiendo material. La correa dentada es capaz de desgastarse de la misma manera que, por ejemplo, neumático. Si se usa el material de la correa, puede ocurrir para abrirlo o deslizarse. Especialmente a menudo esto sucede en grandes cargas en el motor del motor. Por ejemplo, al rastrear un remolque o remolque, así como en el clima húmedo.

- Cinturón de abrasión. Esto sucede, como regla general, con la desviación de la polea y el rodillo del tensor de la posición trasera, así como cuando el mal funcionamiento del cojinete y la temperatura elevada. En caso de inspección, puede notar el desgaste de los dientes del cinturón, su base de tejido (fibras de tela dilatada y textura desigual).

- Desprendimiento o grietas. Esta característica de la boca es obvia. Es necesario explorar la superficie trasera y delantera del cinturón. La presencia de grietas, especialmente si hay muchos de ellos, indica un fuerte desgastado.

- Endurecimiento La superficie opuesta de la correa dentada es la superficie opuesta de la correa es dura, no es elástica y brillo. En este caso, el cinturón se vuelve insensible, como resultado de lo que ya no proporciona el contacto deseado con la polea.

- Alargamiento. El desgaste del material es capaz de liderar un fuerte alargamiento del cinturón, como resultado de lo cual el rodillo de tensión se mueve más allá de los límites permisibles. Esto reduce la rigidez y la tensión total de la correa, y, en consecuencia, el rendimiento general del mecanismo.

- Desviación de la posición designada. Esta característica indica que los elementos internos del rodillo tensor están bastante cerca de la rotura. Si el rodillo falla, conducirá a un mayor ruido, temperatura y vibraciones.

Rompió el cinturón de tiempo, lo que lleva a tal ruptura

El accidente de la correa dentada puede conllevar una masa de consecuencias desagradables que sean diferentes, que varían de la necesidad de reemplazar la correa dentada y para restaurar el mecanismo de distribución de gas y la revisión del motor.

La situación más difícil es cuando la válvula se dobla como resultado de la interrupción del cinturón. Esto simplemente se explica. La brecha puede ocurrir en el período en el que las válvulas se redujeron a la inyección de combustible o la liberación de gases. Al mismo tiempo, el movimiento de los pistones en los cilindros todavía continúa y pueden golpearlos de toda la fuerza. En este caso, la "reunión" puede terminar bastante mal.

Estimar El grado de daño puede evaluarse solo después de desmantelar la cabeza del motor y estimar el estado del sistema de pistón y las válvulas. Cabe señalar que el defecto de la válvula no se puede ver de inmediato, para que los diagnósticos requieren equipos especiales.

Cinturón de tiempo, por qué la sustitución de la correa es mejor hacer en el kit.

Para evitar problemas en el futuro, la sustitución de la correa dentada es deseable producir junto con bombas y rodillos. Sin embargo, esta no es una acción obligatoria, si hay fondos adicionales, es mejor no ser perezoso porque afectará la eficiencia de la nueva correa dentada.

Además, para cumplir con el reemplazo, tendrá que desmontar completamente todos los componentes de este equipo, incluida la bomba con rodillos. Por lo tanto, la sustitución de los consumibles el costo de este procedimiento no aumentará mucho, y no tomará mucho tiempo, pero aumentará la vida útil del agregado reemplazado.

Herramientas, Accesorios, Consumibles

- Se dirige a "10", "12", "14", "17", "32".

- Énfasis ajustable.

- Hexágono en "5".

- La clave para "41".

- Passatia.

Técnica de seguridad

Es imposible trabajar bajo el vehículo si se publica solo en el conector. Como seguro en Obligatorio, use la estación de condición de fábrica. Está prohibido colgar el auto en dos o más gatos. Para proteger sus manos de moretones y cortes con operaciones de "poder", debe trabajar en guantes.

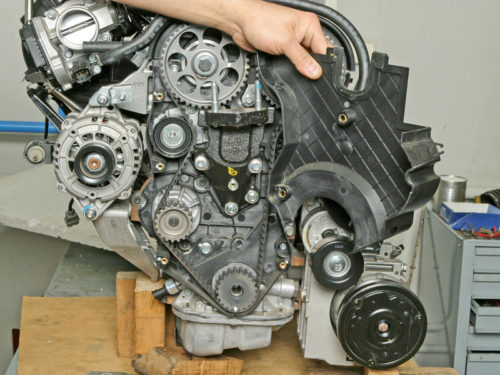

Reemplazo de la correa dentada Chevrolet Lacetti, paso a paso.

- Abra el capó y desmonte un forro decorativo con un motor, para lo que necesita desatornillar cuatro tuercas.

- Para mayor comodidad, desmantele la carcasa del filtro de aire. Para hacer esto, con la cubierta del filtro de aire, desenroscamos los cuatro tornillos, así como la capa de boquilla de aire. Desmontamos la tapa y el filtro de aire. Para eliminar la carcasa del filtro, desenrosque dos pernos más.

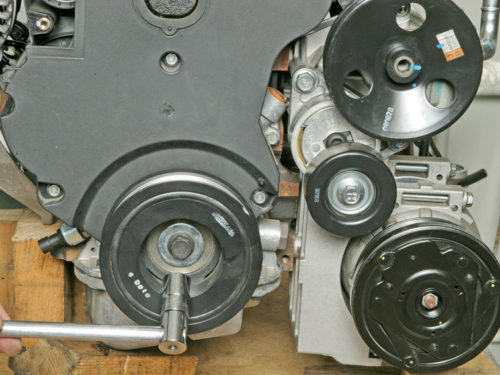

- Ahora retire la correa de transmisión: tire del rodillo de la unidad usando la tecla a "17" y desmonte el cinturón de las poleas. A continuación, debe desatornillar dos pernos y retirar la cubierta superior de la cubierta de tiempo.

- Hacemos la eliminación de la rueda delantera derecha y la antera lateral del motor, que está unida a tres pistones y dos tornillos.

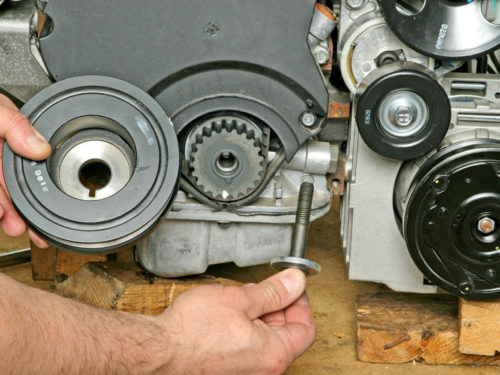

- Destacamos la polea del cigüeñal, para la cual fija el volante con un destornillador ranurado grande a través de la ventana de visualización. Luego, con un soldador y una cabeza en "17", desenroscamos y desmontamos la polea del cigüeñal.

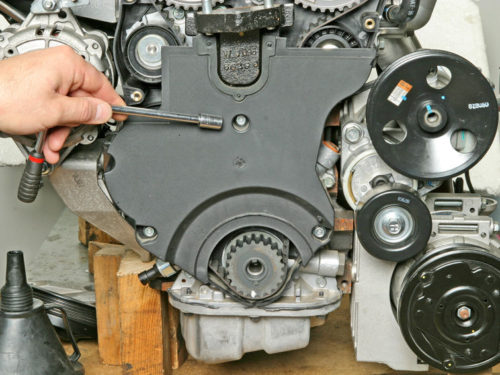

- También debe retirar la cubierta inferior de la correa de distribución, que está unida por tres COGS.

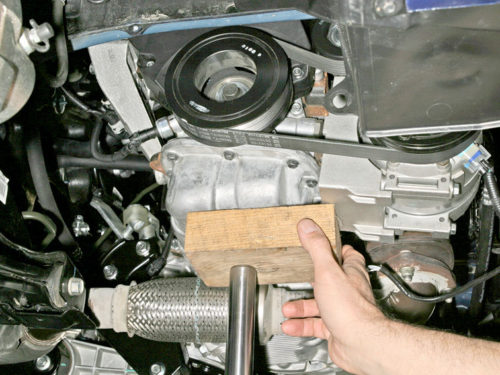

- El siguiente paso es eliminar el soporte del motor, para lo que necesita para instalar un conector adicional para una unidad de potencia debajo del palet. Luego, desenroscamos 3 tuercas y 1 perno usando la tecla a "14" y desmontar el soporte OBS.

- Desenroscimos los cuatro pernos alrededor del perímetro del soporte de soporte y eliminamos el soporte.

- Además, en todas las poleas, establecemos las etiquetas de tiempo. En la polea del cigüeñal, estará abajo.

- Para la conveniencia de la rotación del cigüeñal, apriete el perno de la polea hacia atrás.

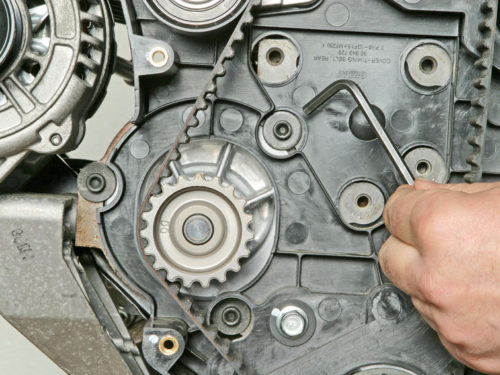

- Ahora proceda a reemplazar la correa dentada. Usando la clave para "14", desatornillamos el rodillo parásito, que se encuentra a la derecha y desmonta el cinturón, después de lo cual nos desatornillamos el tensor de rodillos, que está unido por tres tornillos.

- Antes de montar el cinturón, marque las etiquetas, ya que después de eliminarlos podrían ser eliminados.

- Cuando se mantiene solo para usar un cinturón en la bomba, mueva el tensor de rodillos, después de lo cual está hasta el final de la correa y verifique la instalación de las etiquetas.

- A continuación, desplace el cigüeñal en el sentido de las agujas del reloj en una o dos giras y revise las etiquetas nuevamente.

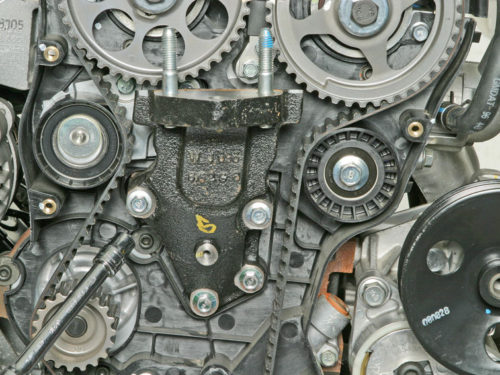

Consejos PROFI, cómo revisar la tensión de la correa de distribución.

Para verificar la tensión de la correa de distribución, gire el cigüeñal dos a tres veces en el sentido de las agujas del reloj y mire los dientes de rodillos del tensor. Es necesario que se encuentren uno frente al otro, además de unos pocos milímetros. Si las lecturas difieren, deberá ajustar la tensión de la correa con las bombas.

Materiales relacionados

- Estufa 2110, mala cálida cálida 2110, sistema de calefacción VAZ 2110, reparando el sistema de calefacción VAZ 2110 con sus propias manos.

- VAZ 2114 estufa sopla con aire frío, estufa 2114, estufa de mala cálida VAZ 2114, dispositivo y reparación de calefacción VAZ 2114 Hágalo usted mismo, eliminando la estufa VAZ 2114

- Cómo subdominizar el coche. Cómo poner un gato. Tipos de tomas para automóviles.

- VAZ 2109 Bloque de fusibles, VAZ 2109 Bloque de fusibles Carburador, VAZ 2109 Inyector de bloques de fusibles, VAZ 2109 Bloque de fusibles, VAZ 2109 Bloque de fusibles, Bloque de fusibles VAZ 2109

- Catalizador de gases de escape del coche, catalizador defectuoso, ventajas y contras del catalizador, cómo cambiar el catalizador en el avión

- Estufa soplando aire frío VAZ 2114, mal soplando la estufa Vaz 2114, ¿por qué soplando mal la estufa VAZ 2114?

- ¿Cómo descubrir al propietario del automóvil por el número de su automóvil, verifique el automóvil por el número de la máquina de policía de tráfico, consulte el automóvil por el número de estado del automóvil gratis

- Cómo elegir neumáticos usados, consejos útiles

- Carretera de invierno, presión en neumáticos de coche de pasajeros en invierno, buena batería para el automóvil en invierno, ya sea para calentar el auto en invierno.

- En invierno, el coche está mal empezado. Cómo hacer un auto en invierno, ¿necesita calentar el auto en invierno, consejos útiles?

- Máquinas de consumo de combustible económico, el consumo más económico del automóvil.

- Neumáticos Marcas para automóviles de pasajeros, etiquetado de etiquetado de neumáticos de automóviles, protector de neumáticos de coche de pasajeros residuales, cómo elegir un neumático en una marca de automóviles, patrón de la banda de rodadura del neumático del coche

- Operación de transmisión de trabajo, trabajo de embrague de caja de cambios mecánica, conducción con caja de cambios manual, consejos útiles

- Peugeot 206 sedán de haz trasero, dispositivo de haz trasero PEUGEOT 206. PEUGEOT TRASERO PEUGEOT 206 Mal funcionamiento, reparación de la viga trasera Peugeot 206

- Combustible diesel en invierno, aditivo para combustible diesel en invierno, cómo elegir el mejor combustible diesel

- El invierno diesel no comienza. Cómo comenzar Diesel en invierno, calefacción diesel en invierno.

- Neumáticos de bridgestone japoneses, neumáticos de bridgestone tachonados de invierno, neumáticos bridgestone de marca

- Decodificación de marcado de neumáticos para automóviles de pasajeros, llantas de etiquetado, cómo elegir los neumáticos adecuados en los discos

- Motor diesel en invierno, lanzamiento del motor diesel en invierno, qué aceite para llenar un motor diesel en invierno, consejos útiles

- Luz de retroiluminación LED del automóvil, la luz de fondo de la parte inferior del automóvil, la luz de fondo de las piernas en el automóvil, la luz de fondo en la puerta del automóvil, la luz de fondo del automóvil está bien.

- Neumáticos recuperados, neumáticos de bus, protector de neumáticos restaurado, ¿puedo usarlos?

- Elija neumáticos de invierno, que es un neumáticos de invierno, que la presión en los neumáticos de invierno debe estar marcada con neumáticos de invierno, cómo elegir los neumáticos de invierno adecuados, los mejores neumáticos de invierno 2019

- Dirección de ferrocarril, golpe de rack de dirección, razones para el golpe y la reparación del bastidor de dirección lo hace usted mismo

- Los neumáticos de automóviles sin intermediarios, un conjunto para la reparación de neumáticos sin cámara, la reparación del neumático sin cañón, hágalo usted mismo.

- Neumáticos rusos, neumáticos rusos, neumáticos rusos, neumáticos de toda la temporada, neumáticos Voronezh AMTEL, Neumáticos "Matador Omsk Tire", KAMA-LIRIONS son autobuses de clase mundial

- Cómo abrir un auto sin clave. Perdí la llave del auto que hacer, la llave del auto dentro del auto.

- Neumáticos silenciosos, neumáticos de invierno tranquilos, autobús con tachuelas tranquilos, que los neumáticos para elegir, los neumáticos de resumen

- Neumáticos y seguridad, seguridad del autobús, por qué es necesario monitorear constantemente los neumáticos de automóviles.

- Reglas de conducción segura del automóvil en la lluvia y aguanieve, conducción segura del automóvil para principiantes.

- Convertidor de óxido que es mejor para los autos, los convertidores de óxido para elegir cómo usar el transductor de óxido, los profesionales

- Pulir el cuerpo del auto hacerlo usted mismo, cómo elegir una pasta de pulido, consejos útiles

- Durabilidad del motor, vida del motor, cómo extender la vida del motor.

- Llamar al coche. Golpear al mover un coche. ¿Qué puede llamar al coche? Cómo determinar la causa del golpe.

- ABS Car, ¿qué es el auto de ABS, el mal funcionamiento del sistema ABS, los diagnósticos de ABS?

- Adelantar un automóvil cuando puede comenzar a adelantar un automóvil, reglas de reglas de tráfico

- Bomba de combustible VAZ 2110, VAZ 2110 Esquema de gasolina, dispositivo de bomba de combustible VAZ 2110, reparación de gasolina VAZ 2110,

- Antenas automotrices para radio, dispositivo de antena automotriz, antena de automóvil.

- Suspensión delantera Kalina, dispositivo de suspensión delantero Kalina, golpe en suspensión delantera Kalina, reparación de suspensión delantera Kalina

- Aceite de amortiguador, los mejores amortiguadores de aceite, bombear los amortiguadores de aceite, cómo bombear correctamente el amortiguador de aceite

- El mal funcionamiento del embrague, toca el embrague, causa un mal funcionamiento del embrague, cómo eliminar

Comentarios