Al conducir en un automóvil, a menudo es posible observar la ocurrencia del zumbido característico, que puede verlo con el tiempo. Además, cambia dependiendo del estado de la superficie de la carretera. En un buen camino, el zumbido desaparece o disminuye, por lo que puede parecer que no hay necesidad de reparar, pero tan pronto como las ruedas van a un mal camino, el zum aparece de nuevo. Además, a alta velocidad, puede escuchar un relieve específico. La razón de la aparición de estos síntomas, por regla general, es la culpa del cojinete del cubo. Vale la pena señalar que si no reemplaza un rodamiento de zumbidos de manera oportuna, entonces cuando la conduce puede atascarse, lo que es extremadamente peligroso y representa una amenaza para la vida, por lo tanto, con las más mínimas manifestaciones de los síntomas de mal funcionamiento descritos anteriormente, Debe ser reemplazado por el cojinete del hub lo antes posible. Sobre esto más allá en el artículo.

Contenido

- Hub de rodamiento, qué tareas que realiza.

- Rodamiento de rodillos, dispositivo, ventajas y desventajas.

- Rodamiento diagonal, dispositivo, ventajas y desventajas.

- El momento del encendido, lo que es y, como un torque del rodamiento afecta la duración de la operación.

- El cojinete del cubo es defectuoso, signos de rotura.

- Herramientas y accesorios para reemplazar el cojinete del cubo, la seguridad.

- Reemplazo del cojinete delantero, instrucciones paso a paso

- Reemplazo del cojinete de la rueda trasera, instrucción paso a paso

- Consejos PROFI, cómo hacer un trabajo correctamente, qué lubricante es mejor usar para cojinete

Hub de rodamiento, qué tareas que realiza.

El rodamiento es un mecanismo que soporta parte del soporte. Es capaz de mantener el eje, el eje o cualquier otro elemento, pero en cualquier caso, su propósito principal es la fijación del eje en el espacio, lo que garantiza su distribución o rotación libre. La segunda función del cojinete del cubo es la percepción de la carga mecánica, así como su transferencia a otros elementos.

El cojinete del hub es un mecanismo que es un rodamiento. Proporciona una rotación suave de la rueda alrededor del eje. Estos rodamientos son de una sola fila y doble fila, así como de tipo abierto y cerrado. Se utilizan en pasajeros y camiones. Los cojinetes de las ruedas para las ruedas delanteras y traseras difieren significativamente entre sí.

Los cojinetes del cubo de coches están constantemente sometidos a cargas extremas. Incluye diferencias de alta temperatura, impacto ambiental, la formación de cargas de choque al ingresar a los pozos, la dirección, los frenos, la unidad. Vale la pena señalar que la contrasa no debe evitar la rotación de la rueda, que debe girar con una fricción mínima y un ruido permitido.

Rodamiento de rodillos, dispositivo, ventajas y desventajas.

Los rodamientos de rodillos son muy susceptibles a la instalación, que, si se lleva a cabo incorrectamente, es capaz de eliminar instantáneamente la parte en orden. Los novatos que no conocen esta característica de los rodamientos de rodillos a menudo engañan a los trabajadores sin escrúpulos del STO, que producen el reemplazo de este elemento a la mano de la ambulancia y mal.

Rodamiento diagonal, dispositivo, ventajas y desventajas.

Los rodamientos diagonales son capaces de soportar cargas pesadas y tienen una excelente resistencia al desgaste.

Sin embargo, su trabajo, como los rodamientos de rodillos, depende de la instalación correcta (ajuste fuerte), de lo contrario fallarán.

El momento del encendido, lo que es y, como un torque del rodamiento afecta la duración de la operación.

El momento del apretamiento del rodamiento es un evento que debe hacerse con precisión de acuerdo con las recomendaciones del fabricante del vehículo. Como ya se mencionó, el ajuste incorrecto del rodamiento implica su desglose.

Si antes, para ajustar los rodamientos, se requieren habilidades especiales, así como la presencia de herramientas especiales que fueron difíciles de encontrar en ese momento, hoy en día, hoy no hay problemas en este sentido. Ahora, cada propietario de cada automóvil puede comprar el kit de herramientas necesario y obtener datos que le permitan controlar de forma independiente el estado de los rodamientos y otros elementos del automóvil.

El cojinete del cubo es defectuoso, signos de rotura.

Los principales signos del mal funcionamiento del cojinete del centro de automóviles son:

- Humo fuerte o ruido que se escucha desde detrás del vehículo. Si el cubo de cojinete está defectuoso, el ruido se vuelve más cuando se gira.

- La aparición de la reacción en la rueda trasera, que está acompañada de ruido o toque.

Herramientas y accesorios para reemplazar el cojinete del cubo, la seguridad.

- Extractor especial.

- Martillo.

- Pinzas para desmantelar un parado de anillos.

- Clave a las 17.

- Un hexágono clave en 10.

- Destornillador.

- Cincel.

Antes de la sustitución, no se olvide de colocar las barras anti-tartares debajo de las ruedas traseras, y debajo del cuerpo.

Reemplazo del cojinete delantero, instrucciones paso a paso

- Debilitando los pernos de sujeción de la rueda delantera.

- Rodando la nuez nave.

- A continuación, levante el automóvil hasta el gato y desmonte la rueda delantera.

- Encontramos una tuerca que corrige la punta de la dirección, luego lo desenreda.

- Usando un extractor, se presiona una punta de dirección.

- Toma el último desde la rejilla delantera.

- Encontramos y eliminamos la tapa de dos metales, la fijación de la calibradora.

- Destornille los pernos del calibrador.

- Para que el calibrador no interfiera, quítelo, después de lo cual nos colgamos en el cable.

- Luego desenrosque la bola de la bola de soporte.

- Conozca el soporte de la bola.

- Retire el disco de freno.

- Ahora debes desenroscar la tuerca desde el centro.

- Debajo de la capucha debilita las dos nueces que sostienen un bastidor en una taza.

- Regresamos al auto y retiramos la palanca de la bola de apoyo.

- A continuación, tire del bastidor de la escena, sin embargo, debe usarse aquí para no tirar el eje de transmisión.

- Ahora retire completamente el bastidor.

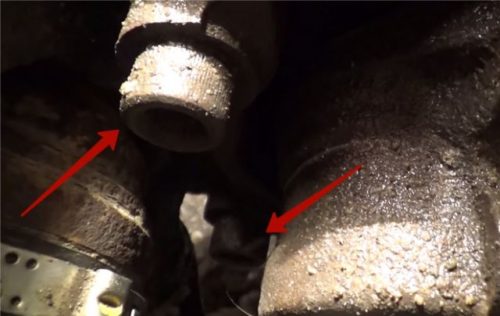

- Cuando se extiende el cubo del rodamiento, en realidad hay un anillo interior.

- El rodamiento está eliminado, y el anillo cortó el molinillo.

- El nuevo elemento es accionado u insertado suavemente en su lugar.

Reemplazo del cojinete de la rueda trasera, instrucción paso a paso

Reemplazo del cojinete del cubo trasero se hace de la misma manera:

- Retire la rueda trasera.

- Yo bajo el soporte del cuerpo.

- Destacamos los tornillos del eje del hub y el tambor. Si es necesario, Splash WD-40.

- Retire el tambor de freno.

- Desmontamos la tapa del cubo.

- Desmontamos la tuerca, a través de la cual el tapón está vestido. Se le debe acceder, después de lo cual se retira las pinzas.

- Retire del eje el anillo interior del cojinete con las removimientos o simplemente retire el eje al desatornillar cuatro tuercas desde el reverso.

- Con un destornillador, eliminamos el clip, y con la ayuda de un cincel, golpee con cuidado el anillo interior del eje.

- Prescribiremos un nuevo rodamiento con la ayuda de un clima antiguo.

- Después del montaje, arrastramos la tuerca, aplicando un cierto esfuerzo.

Después de la operación, debe conducir tres o cuatro días. Luego, de nuevo, debe sacar la tuerca para quitar la contracción.

Consejos PROFI, cómo hacer un trabajo correctamente, qué lubricante es mejor usar para cojinete

- Es deseable reemplazar los rodamientos en las ruedas traseras o delanteras, independientemente de si el valor allí está la parte allí.

- Elija el lubricante correcto debajo de los rodamientos.

- Es imposible batir el martillo justo en el rodamiento, es necesario hacerlo con una tableta de madera.

- En los nodos del cubo, es imposible poner un espacio, porque en la fábrica se recolectaron teniendo en cuenta las brechas.

- Al reemplazar el cojinete, asegúrese de verificar la condición del eje y el caso.

- No puede ajustar o mover el sello en los nodos de las ruedas.

Materiales relacionados

- Estufa 2110, mala cálida cálida 2110, sistema de calefacción VAZ 2110, reparando el sistema de calefacción VAZ 2110 con sus propias manos.

- VAZ 2114 estufa sopla con aire frío, estufa 2114, estufa de mala cálida VAZ 2114, dispositivo y reparación de calefacción VAZ 2114 Hágalo usted mismo, eliminando la estufa VAZ 2114

- Cómo subdominizar el coche. Cómo poner un gato. Tipos de tomas para automóviles.

- VAZ 2109 Bloque de fusibles, VAZ 2109 Bloque de fusibles Carburador, VAZ 2109 Inyector de bloques de fusibles, VAZ 2109 Bloque de fusibles, VAZ 2109 Bloque de fusibles, Bloque de fusibles VAZ 2109

- Catalizador de gases de escape del coche, catalizador defectuoso, ventajas y contras del catalizador, cómo cambiar el catalizador en el avión

- Estufa soplando aire frío VAZ 2114, mal soplando la estufa Vaz 2114, ¿por qué soplando mal la estufa VAZ 2114?

- ¿Cómo descubrir al propietario del automóvil por el número de su automóvil, verifique el automóvil por el número de la máquina de policía de tráfico, consulte el automóvil por el número de estado del automóvil gratis

- Cómo elegir neumáticos usados, consejos útiles

- Carretera de invierno, presión en neumáticos de coche de pasajeros en invierno, buena batería para el automóvil en invierno, ya sea para calentar el auto en invierno.

- En invierno, el coche está mal empezado. Cómo hacer un auto en invierno, ¿necesita calentar el auto en invierno, consejos útiles?

- Máquinas de consumo de combustible económico, el consumo más económico del automóvil.

- Neumáticos Marcas para automóviles de pasajeros, etiquetado de etiquetado de neumáticos de automóviles, protector de neumáticos de coche de pasajeros residuales, cómo elegir un neumático en una marca de automóviles, patrón de la banda de rodadura del neumático del coche

- Operación de transmisión de trabajo, trabajo de embrague de caja de cambios mecánica, conducción con caja de cambios manual, consejos útiles

- Peugeot 206 sedán de haz trasero, dispositivo de haz trasero PEUGEOT 206. PEUGEOT TRASERO PEUGEOT 206 Mal funcionamiento, reparación de la viga trasera Peugeot 206

- Combustible diesel en invierno, aditivo para combustible diesel en invierno, cómo elegir el mejor combustible diesel

- El invierno diesel no comienza. Cómo comenzar Diesel en invierno, calefacción diesel en invierno.

- Neumáticos de bridgestone japoneses, neumáticos de bridgestone tachonados de invierno, neumáticos bridgestone de marca

- Decodificación de marcado de neumáticos para automóviles de pasajeros, llantas de etiquetado, cómo elegir los neumáticos adecuados en los discos

- Motor diesel en invierno, lanzamiento del motor diesel en invierno, qué aceite para llenar un motor diesel en invierno, consejos útiles

- Luz de retroiluminación LED del automóvil, la luz de fondo de la parte inferior del automóvil, la luz de fondo de las piernas en el automóvil, la luz de fondo en la puerta del automóvil, la luz de fondo del automóvil está bien.

- Neumáticos recuperados, neumáticos de bus, protector de neumáticos restaurado, ¿puedo usarlos?

- Elija neumáticos de invierno, que es un neumáticos de invierno, que la presión en los neumáticos de invierno debe estar marcada con neumáticos de invierno, cómo elegir los neumáticos de invierno adecuados, los mejores neumáticos de invierno 2019

- Dirección de ferrocarril, golpe de rack de dirección, razones para el golpe y la reparación del bastidor de dirección lo hace usted mismo

- Los neumáticos de automóviles sin intermediarios, un conjunto para la reparación de neumáticos sin cámara, la reparación del neumático sin cañón, hágalo usted mismo.

- Neumáticos rusos, neumáticos rusos, neumáticos rusos, neumáticos de toda la temporada, neumáticos Voronezh AMTEL, Neumáticos "Matador Omsk Tire", KAMA-LIRIONS son autobuses de clase mundial

- Cómo abrir un auto sin clave. Perdí la llave del auto que hacer, la llave del auto dentro del auto.

- Neumáticos silenciosos, neumáticos de invierno tranquilos, autobús con tachuelas tranquilos, que los neumáticos para elegir, los neumáticos de resumen

- Neumáticos y seguridad, seguridad del autobús, por qué es necesario monitorear constantemente los neumáticos de automóviles.

- Reglas de conducción segura del automóvil en la lluvia y aguanieve, conducción segura del automóvil para principiantes.

- Convertidor de óxido que es mejor para los autos, los convertidores de óxido para elegir cómo usar el transductor de óxido, los profesionales

- Pulir el cuerpo del auto hacerlo usted mismo, cómo elegir una pasta de pulido, consejos útiles

- Durabilidad del motor, vida del motor, cómo extender la vida del motor.

- Llamar al coche. Golpear al mover un coche. ¿Qué puede llamar al coche? Cómo determinar la causa del golpe.

- ABS Car, ¿qué es el auto de ABS, el mal funcionamiento del sistema ABS, los diagnósticos de ABS?

- Adelantar un automóvil cuando puede comenzar a adelantar un automóvil, reglas de reglas de tráfico

- Bomba de combustible VAZ 2110, VAZ 2110 Esquema de gasolina, dispositivo de bomba de combustible VAZ 2110, reparación de gasolina VAZ 2110,

- Antenas automotrices para radio, dispositivo de antena automotriz, antena de automóvil.

- Suspensión delantera Kalina, dispositivo de suspensión delantero Kalina, golpe en suspensión delantera Kalina, reparación de suspensión delantera Kalina

- Aceite de amortiguador, los mejores amortiguadores de aceite, bombear los amortiguadores de aceite, cómo bombear correctamente el amortiguador de aceite

- El mal funcionamiento del embrague, toca el embrague, causa un mal funcionamiento del embrague, cómo eliminar

Comentarios