Pás plynárenskej mechanizmu je nepostrádateľným atribútom pre väčšinu moderných vozidiel, vrátane vozidla Chevrolet Lacetti. Cez vynikajúce jednoduchosť, to je pomerne dôležitý údaj pre motor s vnútorným spaľovaním. Výmena rozvodového remeňa na Chevrolet Lacetti - udalosť je pomerne časovo náročné, ale je to úplne jednoduché, keď sa presne jednať pod pokyny.

Obsah

- Rozvodový remeň, aké úlohy robiť rozvodový remeň

- Rozvodový remeň, ako to funguje a z akého materiálu

- Ako často meniť rozvodový remeň

- Koľko meniť rozvodový remeň, čo znamenie hovorí o nutnosti výmeny rozvodového remeňa

- Zlomil rozvodový remeň, ktorý vedie toto členenie

- Rozvodový remeň, prečo nahradenie pásu je lepšie robiť v súprave

- Náradie, príslušenstvo, spotrebný materiál

- bezpečnostná technika

- Výmena rozvodového remeňa Chevrolet Lacetti, krok za krokom práce

- Tipov Profi, ako skontrolovať napnutie rozvodového remeňa

Rozvodový remeň, aké úlohy robiť rozvodový remeň

Úlohou je, že vačkový hriadeľ sa otáča rýchlosťou, presne identické polovicu objemu kľukového hriadeľa. Pol pred sto rokmi, pohon GRM reťaz sa používajú v automobilovom priemysle, a všetky pokusy prispôsobiť pás pre to bolo nedorozumenie. Koľko času uplynulo, než hnací remeň začala dominovať. Ale má niekoľko významných výhod - zjednodušiť dizajn, nízka hlučnosť a zníženie hmotnosti pohonnej jednotky.

Dnes výrobcovia dávajú prednosť inštalácii pásov pásov na ich autách. Je však nemožné jednoznačne povedať, že reťazec je horší ako pás. Reťazová jednotka má tiež svoju výhodu - trvanlivosť, korelovaná s trvaním samotného motora. Aj v našom čase niektoré výrobné spoločnosti zastavia svoj výber na mechanizmus reťazca. Okrem toho sú takéto motory zvyčajne vybavené automatickými napínami. Servisná životnosť bežného pásu veľmi zriedka presahuje 60 tisíc kilometrov a jednoduchosť dizajnu znamená potrebu trvalého servisu - pull-up, výmenu, kontrolu nad stavom pásu.

Rozvodový remeň, ako to funguje a od akého materiálu

Aby sa rozvodový remeň mohol spoľahlivo pracovať, musia byť dodržané nasledujúce podmienky - optimálny stav kladiek a valcov, pozdĺž ktorej sa pás pohybuje, správne napätie pásu, jeho absolútna ochrana proti olejom a nečistote. Konštrukcia pásu je pomerne jednoduchý a niečo podobá pneumatike.

Preto väčšina spoločností, ktoré sa špecializujú na výrobu pneumatík, tiež vyrábajú pásy. Základom rozvodového pásu - kábel - plexus od trvanlivých vlákien z sklolaminátu. Vnútorné šnúry sú zuby z materiálov odolných voči opotrebeniu (spravidla, nylon) a mimo neho chráni vrstvu gumy, ktorej hrúbka je asi päť milimetrov. Dizajn pásov je dosť rôznorodý. Môže sa líšiť v šírke pásu, počet a krok zubov, ako aj ich profilu (existuje približne dvadsať typov profilov zubov).

Ako často menia časový pás

Výmena načasovaného remeňa na Chevrolet Lacetti, podľa predpisov o údržbe, je potrebné vykonávať každých 60 000 kilometrov. Väčšina špecialistov však odporúča znížiť zmenu v období náhrady z dôvodu zložitých prevádzkových podmienok. Pokiaľ ide o overenie stavu pásu, potom na vozidle Chevrolet Lacetta by mala byť vykonaná každých 30 tisíc kilometrov.

Koľko zmeniť časovací remeň, aké značky hovoria o potrebe vymeniť časový pás

- Nosenie materiálu. Rozvodový remeň je schopný nosiť rovnakým spôsobom, ako napríklad pneumatiky. Ak sa nosný materiál opotrebovaný, môže dôjsť k otvoreniu alebo pošmyknutiu. Zvlášť často sa to deje pri veľkých zaťaženiach na motorovom motore. Napríklad pri sledovaní prívesu alebo prívesu, ako aj v mokrom počasí.

- Opýtanie. To sa deje spravidla, s odchýlkou \u200b\u200bkladky a viazača napínača zo zadnej polohy, ako aj pri poruche ložísk a zvýšenej teplote. V prípade kontroly si môžete všimnúť opotrebovanie pásových zubov - jeho tkanivové základne (rozšírené tkaniny a nerovnomerné textúry).

- Alebo trhliny. Táto vlastnosť opornosti je zrejmá. Je potrebné preskúmať zadný a predný povrch pásu. Prítomnosť trhlín, najmä ak existuje mnoho z nich, označuje silnú nosu.

- Tvrdenie opačného povrchu ozubeného remeňa je opačný povrch pásu je tvrdý, nie elastický a trbliet. V tomto prípade sa pás stane nebežným, v dôsledku čoho už neposkytuje požadovaný kontakt s remenicou.

- Predĺženie. Používanie materiálu je schopné viesť silnú predĺženie pásu, v dôsledku čoho napínací valec sa pohybuje mimo prípustných hraníc. Tým sa znižuje tuhosť a celkové napätie opasok a následne celkový výkon mechanizmu.

- Odchýlky od určenej pozície. Táto funkcia označuje, že vnútorné prvky napínacieho valca sú veľmi blízko k zlomu. Ak valček zlyhá, povedie k zvýšeniu hluku, teploty a vibrácií.

Rozbil rozvodový pás, ktorý vedie taký poruchový

Zlyhanie rozvodového pásu môže znamenať hmotnosť nepríjemných následkov, ktoré sú odlišné od nutnosti vymeniť časovacího remeňa a obnoviť mechanizmus distribúcie plynu a revíziu motorov.

Najťažšia situácia je, keď je ventil ohnutý v dôsledku prestávky pásu. Toto je jednoducho vysvetlené. Medzera sa môže stať v období, keď ventily klesli na vstrekovanie paliva alebo uvoľňovanie plynov. V rovnakej dobe, pohyb piestov vo valci stále pokračuje a sú schopní ich zasiahnuť z celej sily. V tomto prípade môže "stretnutie" skončiť dosť zle.

Odstráňte stupeň poškodenia možno vyhodnotiť len po demontáži hlavy motora a odhadnúť stav piestu a ventilov. Treba poznamenať, že vada ventilu nemôže okamžite vidieť - pre diagnostiku vyžaduje špeciálne vybavenie.

Rozvodový remeň, prečo je náhrada pásu lepšia v súprave

Aby sa zabránilo problémom v budúcnosti, nahradenie rozvodového pásu je žiaduce vyrábať spolu s čerpadlami a valcami. Nie je to však povinné opatrenia, ak existujú dodatočné finančné prostriedky, je najlepšie nie je lenivý, pretože to ovplyvní účinnosť nového rozvodového pásu.

Okrem toho, aby ste splnili nahradenie, budete musieť úplne rozobrať všetky komponenty tohto zariadenia, vrátane čerpadla s valcami. Výmena spotrebného materiálu teda sa náklady na tento postup nezvýši, a to nebude trvať veľa času, ale zvýši životnosť nahradeného kameniva.

Nástroje, príslušenstvo, spotrebný materiál

- Hlavy na "10", "12", "14", "17", "32".

- Nastaviteľný dôraz.

- Šesťuholník na "5".

- Kľúč "41".

- Pasatia.

Bezpečnostná technika

Nie je možné pracovať pod vozidlom, ak je odoslaný len na zdviháku. Ako poistenie v povinnom, použite stavovú stanicu. Je zakázané zavesiť auto na dvoch alebo viacerých jadier. Na ochranu vašich rúk pred podliatinami a rezmi s "Power" operácií by ste mali pracovať v rukavíc.

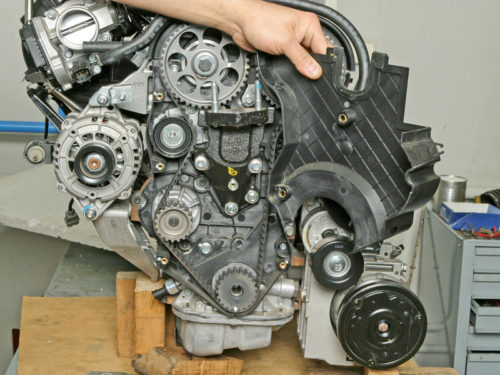

Výmena ozubeného remeňa Chevrolet Lacetti, krok za krokom

- Otvorte kapucňu a demontujte dekoratívne obloženie s motorom, pre ktorý potrebujete odskrutkovať štyri orechy.

- Pre pohodlie demontujte kryt vzduchového filtra. K tomu, s krytom vzduchového filtra, odskrutkujeme štyri skrutky, ako aj srsť vzduchovej trysky. Veko a vzduchový filter demontujeme. Ak chcete odstrániť samotný kryt filtra, odskrutkujte dva viac skrutiek.

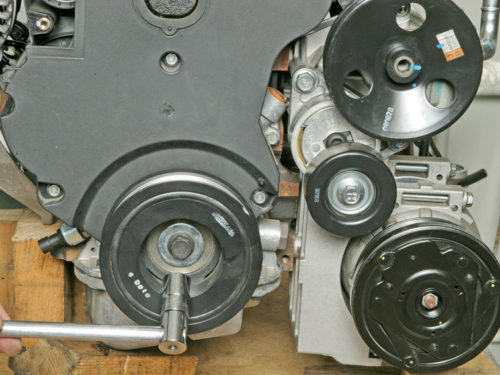

- Teraz odstráňte hnací pás - vytiahnite valček pohonu pomocou tlačidla na "17" a demontujte pás z remeník. Potom by ste mali odskrutkovať dva skrutky a odstrániť horný kryt časového krytu.

- Robíme odstránenie predného pravého kolesa a bočný anthera motora, ktorý je pripevnený na tri piesty a dva skrutky.

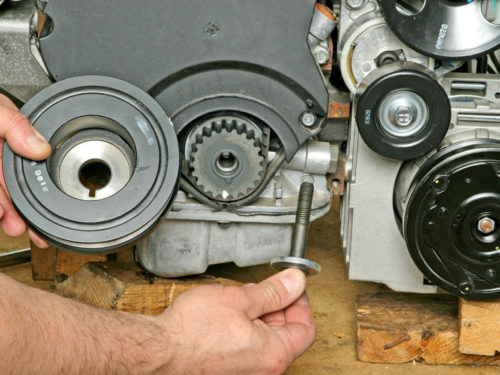

- Odskrutkujeme kľučku kladkovej hmoty, pre ktorú si zotrvačník opravíte pomocou veľkého skrutkovača skrutkovača. Potom, so zváraním a hlave na "17" odskrutkujeme a demontujeme kľučku kľučku.

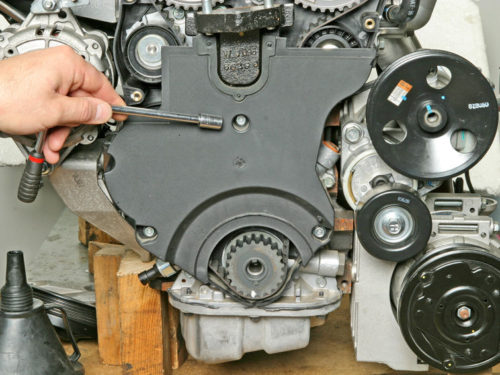

- Tiež by ste mali odstrániť spodný kryt rozvodového pásu, ktorý je pripojený tromi ozubami.

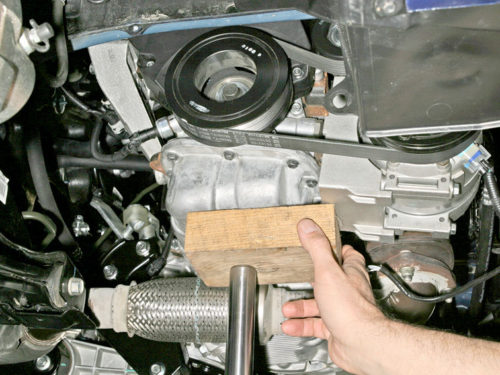

- Ďalším krokom je odstrániť podporu motora, pre to, čo potrebujete na inštaláciu prídavného konektora pre napájaciu jednotku pod paletou. Potom odskrutkujeme 3 orechy a 1 skrutku pomocou klávesu na "14" a demontovať obsovú podporu.

- Odskrutkujte štyri skrutky okolo obvodu nosnej konzoly a vyberieme držiak.

- Ďalej, na všetkých kladkách, nastavujeme časovacie značky. Na kľučkovej kľuke bude nižšie.

- Pre pohodlie otáčania kľukového hriadeľa, utiahnite skrutku kladky.

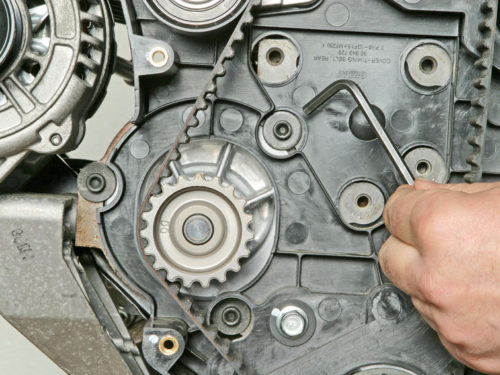

- Teraz postupujte podľa výmeny rozvodového pásu. Pomocou klávesu na "14" odskrutkujeme parazitický valček, ktorý sa nachádza na pravej a demontujeme pás, po ktorom odskrutkujeme valčekový napínač, ktorý je pripojený tromi skrutkami.

- Pred montážou pásu skontrolujte značky, pretože po odstránení by mohli byť vyradené.

- Keď zostane len nosiť opasok na čerpadle, presuňte napínač valčekov, po ktorom je až na koniec pásu a skontrolujte inštaláciu štítkov.

- Ďalej prejdite na kľukový hriadeľ v smere hodinových ručičiek na jednej alebo dvoch otočení a znova skontrolujte štítky.

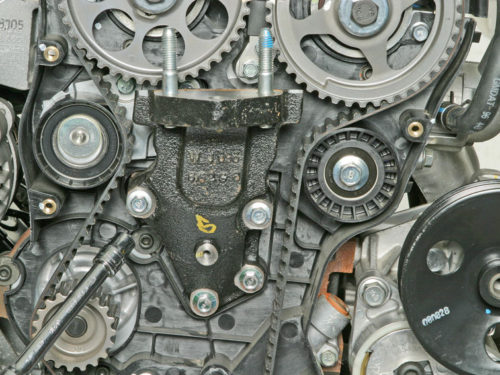

Tipy PROFI, ako skontrolovať napätie načasovania remeňa

Ak chcete skontrolovať napätie načasovaného remeňa, otočte kľukového hriadeľa dvakrát až trikrát v smere hodinových ručičiek a pozrite sa na viazačské valčekové zuby. Je potrebné, aby sme sa dostali oproti sebe - plus-mínus niekoľko milimetrov. Ak sa čítanie líšia, budete musieť nastaviť napätie pásu pomocou čerpadiel.

Súvisiace materiály

- Sporák 2110, Zlé teplé sporák 2110, VZ 2110 Vykurovací systém, Oprava vykurovacieho systému Vaz 2110 s vlastnými rukami

- VAZ 2114 sporák s studeným vzduchom, sporákom 2114, zlé teplé sporák Vaz 2114, Zariadenie a opravy vykurovania VZ 2114 Do-it-yourself, odstránenie sporák VaZ 2114

- Ako subdominizovať auto. Ako dať zdvihák. Typy konektorov pre autá.

- VZ 2109 FUSE BLOK, VAZ 2109 FUSE BLOCK Karburátor, Vaz 2109 Poistkový blok Injektor, Old VAZ 2109 Poistkový blok, Vaz 2109 Poistkový blok, VIS FUSE BLOK 2109

- Katalyzátor výfukových plynov, chybný katalyzátor, plusy a nevýhody katalyzátora, ako zmeniť katalyzátor na rovinenicitel

- Sporák Fúka studený vzduch VZ 2114, zle fúkanie sporák Vaz 2114, prečo zle fúkané sporák 2114

- Ako zistiť majiteľa vozidla podľa počtu svojho auta, vozidlo skontrolovať počtom dopravnej polície stroje a nechali vozidlo skontrolovať štátnej číslom vozidla zadarmo

- Ako si vybrať opotrebovaných pneumatík Užitočné tipy

- Winter road autá, tlak v pneumatikách pre osobný automobil v zime, dobrá batérie pre auto v zime, či už zahriať auto v zime

- V zime, auto je zle začala. Ako vyrobiť auto v zime, sa budete musieť zahriať auto v zime, užitočné tipy

- Spotreba stroje úsporu paliva najúspornejšie spotrebu auta

- Pneumatiky značky pre osobné automobily, značenie značenie auto pneumatík, reziduálne osobné ochranca auto pneumatík, ako vybrať pneumatiky na značku auta, auto pneumatík dezénu

- Práca prenos operácie, mechanické práce prevodovka spojka, jazda s manuálnou prevodovkou, užitočných tipov

- Zadný nosník PEUGEOT 206 Sedan, Zadné svetlo PEUGEOT 206. Zadný lúč PEUGEOT 206 Porucha, Oprava zadného lúča PEUGEOT 206

- Motorová nafta v zimnom období, prísada do motorovej nafty v zime, ako si vybrať najlepší motorovú naftu

- Diesel zimné nespustí. Ako začať naftu v zime vykurovanie naftu v zime.

- Japonské pneumatiky Bridgestone, Winter Studded Bridgestone pneumatiky, Bridgestone pneumatiky značky

- Označenie pneumatiky dekódovanie osobných automobilov, označovacích kolies, ako si vybrať správne pneumatiky na diskoch

- Dieselový motor v zime, spustenie dieselového motora v zime, aký olej vyplňte dieselový motor v zime, užitočné tipy

- LED podsvietenie automobilu, podsvietenie spodnej časti vozidla, podsvietenie nôh v aute, podsvietenie vo dverách vozidla, podsvietenie vozidla je v poriadku

- Obnovené pneumatiky, autobusová pneumatika, obnovená ochranca pneumatík, môžem ich použiť

- Vyberte si zimné pneumatiky, ktoré sú zimnými pneumatikami, ktorým by mal byť tlak v zimných pneumatikách označený zimnými pneumatikami, ako si vybrať správne zimné pneumatiky, najlepšie zimné pneumatiky 2019

- Riadiaca železničná koľajnica, Klopenie riadiaceho stojana, Dôvody na knock a opravy regálu riadenia

- Automatické pneumatiky, súpravu na opravu bezdušových pneumatík, opravu pneumatiky bez dela

- Ruské pneumatiky, ruské pneumatiky zimné, ruské pneumatiky pre všetky sezóny, pneumatiky Voronezh Amtel, pneumatiky "Matador Omsk Tire", KAMA-pneumatiky sú autobusom svetovej triedy

- Ako otvoriť auto bez kľúča. Stratil kľúč z auta, čo robiť, kľúč z auta vnútri auta

- Tiché pneumatiky, tiché zimné pneumatiky, pokojný autobus, ktorý pneumatiky vybrať, prehľad pneumatík

- Pneumatiky a bezpečnosť, bezpečnosť autobusu, prečo je potrebné neustále monitorovať pneumatiky

- Pravidlá bezpečnej jazdy automobilu v daždi a Slush, bezpečné riadenie vozidla pre začiatočníkov

- RUST CONVERTER, ktorý je lepší pre automobily, RUSTOVÉ CONNERTERS, KTORÉ SA ZVÝŠENIE AKO POUŽÍVAŤ RUSTO

- Leštenie tela auta si to urobí sám, ako si vybrať leštiacu pastu, užitočné tipy

- Trvanlivosť motora, životnosť motora, ako rozšíriť životnosť motora

- Zaklopať v aute. Zaklopať pri pohybe auta. Čo môže zaklopať v aute. Ako určiť príčinu klepania.

- ABS CAR, Čo je ABS Car, ABS Systémová porucha, ABS Diagnostics

- Predbiehanie auta, keď môžete začať predbiehať auto, pravidlá dopravných pravidiel

- Palivové čerpadlo VZ 2110, VAZ 2110 Schéma čerpacej stanice, VZ 2110 Palivové čerpadlo, Vaz 2110 Oprava čerpacej stanice,

- Automobilové antény pre rádio, automobilové antény zariadenie, auto anténa

- Predné odpruženie Kalina, Zariadenie predné odpruženie Kalina, zaklopať v prednej záveske Kalina, Oprava predného odpruženia Kalina

- Olej na tlmič, najlepšie tlmiče oleja, čerpacie tlmiče oleja, ako správne čerpať Tlmič pérovania oleja

- Poruchy spojky, dotýka sa spojky, spôsobuje poruchu spojky, ako eliminovať

Pripomienka