Skúsený motorista sa vždy cíti ako vozidlo, ktoré sa chová na ceste, a na základe jednotlivých vlastností určuje, ktorý systém bude diagnostikovaný. Ak sa nezrovnalosti na ceste čoraz viac prejavujú v kabíne vozidla, potom je najpravdepodobnejší, je čas skontrolovať pozastavenie alebo jeho jednotlivé zložky. O tom ďalej v článku.

Obsah

- Tlmič pérovania, zariadenia a účel

- Kontrola tlmiča nárazov, je možné rozdeliť telo, moderné auto, skontrolovať výkon tlmiča

- Tlmič nárazov nefunguje, ktorý trápne ohrozujú auto a vodič, ak sa tlmič nárazov zlyhal

- Kontrola tlmiča nárazov, ako skontrolovať pomocou tlmiča s vlastnými silami bez demontáže tlmiča nárazov

- Ako skontrolovať Tlmič pérovania pri výkone pomocou zariadenia s pohybom pohybu

- Skúška šoku (šok-test) Diagnostika tlmiča nárazov

- Expresná diagnostika tlmiča nárazov

- Kontrola zaťaženia tlmiča tlmič amplitúdy-rezonancie

- Nové tlmiče tlmiča, ako skontrolovať tlmič nárazov v mieste nákupu od predávajúceho

- Tipy Prof.

Tlmič pérovania, zariadenia a účel

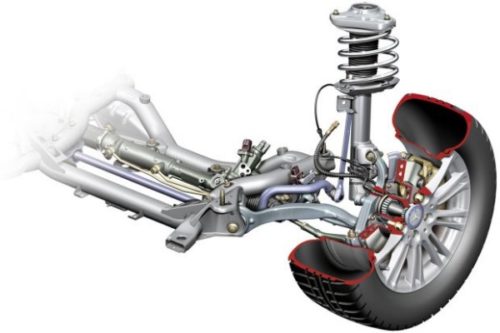

Tlmič nárazov je určený na uhasenie joltov a otrasov, ktoré pri pohybe prijíma telo vozidla pomocou kolies. Okrem toho, tlmiče tlmočníkov poskytujú spoľahlivý kontakt kolesá vozidla s cestmi. Takže ich cieľom je nielen pohodlie, ale bezpečnosť.

Predtým, autá neboli vybavené tlmivými tlmičmi. Ich funkcie boli vykonané pružinami - zhášanie vibrácií sa uskutočnilo v dôsledku trenia listov z nich sa stali navzájom. Rýchlosť, s ktorou by sa autá mohli pohybovať, neustále rastú, v dôsledku toho sa nové systémy museli vyvinúť pre bezpečnosť a pohodlie. Tak, regály existovali vo forme bloku stlačených trecích kotúčov, ktoré fungovali nasledovne: Vibrácie sa rozložili na úkor úsilia, s ktorými boli disky otočené voči sebe navzájom. Po určitom čase bolo potrebné opustiť takýto dizajn, pretože disky boli rýchlo nosené a prehriaty.

V 20. rokoch dvadsiateho storočia sa zistil výstup. Riešením problému bolo použitie kvapaliny, ktorá má vibrácie tela, pohybujúce sa z jednej nádrže do druhého pod tlakom.

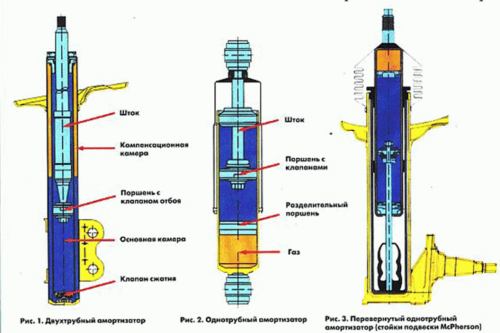

Jeho dizajn môže byť regál rozdelený na množstvo hlavných variácií. V štruktúre sú spravidla jednou trubicou a dvomi potrubím.

Tlmiče nárazov sa vyznačujú typom tekutiny, ktoré sú naplnené - plyn (s plynovou hydraulickou podskou) a hydraulickým. Existujú jednoducho tlmiče plynu, ale používajú sa veľmi zriedka. Plyn v nich je pod vysokým tlakom (asi 60 atm).

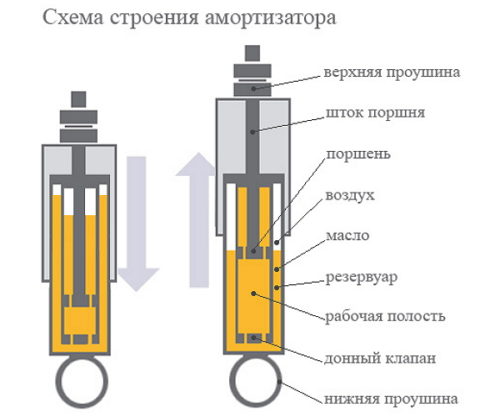

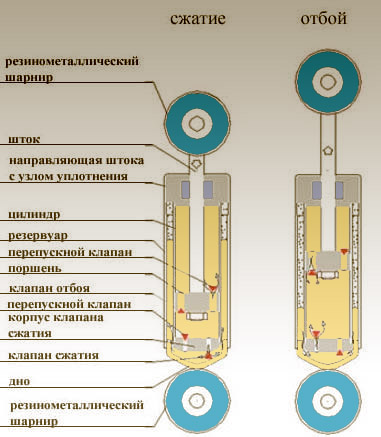

Prevádzka tlmiča nárazov je hydraulická odolnosť alebo odolnosť voči plynu. Olej pôsobí ako kvapalina. Existujú odrody regálov, v ktorých okrem oleja, odpor poskytuje stláčanie a tlakový plyn.

Samotný tlmič je podmienene rozdelený na piest a valca. Vo vnútri valca v závislosti od modifikácie existujú komory - alebo s plynom a maslom, alebo s vzduchom a olejom. V oboch prípadoch piest chodí vo vnútri valca, klesá a stúpa. V druhom prípade piest odoláva tlak vytvorenému tlakovým plynovou komorou. V prvom horizonte sa piest pohybuje odporom, ktorý sa vyskytuje v dôsledku prúdenia oleja pomocou ventilov do inej komory.

Kontrola tlmiča nárazov, je možné rozdeliť telo, moderné auto, skontrolovať výkon tlmiča

Skoršie, na starých modeloch klasických vozidiel s minulými typmi a modelmi tlmiče nárazov, by mohla byť použiteľná funkčnosť regálov veľmi jednoduché - s pomocou banda tela. Komplexná konštrukcia moderného automobilového odpruženia neumožňuje vizuálne urobiť objektívne závery o pomoci tlmiča nárazov. Existuje však množstvo ďalších účinných metód, ktoré budeme zvážiť nižšie.

Tlmič nárazov nefunguje, ktorý trápne ohrozujú auto a vodič, ak sa tlmič nárazov zlyhal

Hlavnou poruchou tlmočníkov je zmena ich prevádzkových parametrov, ku ktorým dochádza v dôsledku narušenia tesnosti, mechanického poškodenia alebo opotrebovania pracovných prvkov (kmeň) tlmiča nárazov.

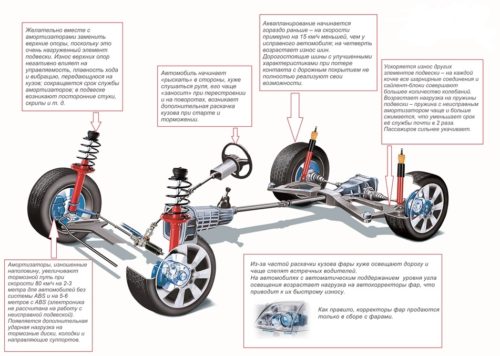

Porucha tlmičov vedie k nasledujúcim dôsledkom:

- Porušenie riadenia automobilov. Pamätajte si, že výraz "Neprišiel som s kontrolou ...". Niektorí vodiči sú niekedy prekvapení - no, ako to môžem zvládnuť s ním? V skutočnosti je všetko jednoduché: pri otáčaní otáčania pri rýchlosti, chybné tlmiče sa spontánne pohybovali metal.

- Znižovanie nosnosti.

- Znížená stabilita vozidla.

- Zvýšenie brzdnej dráhy, riziko "starostlivosti" na stranu s extrémnym alebo stredným brzdením.

- Zrýchlenie opotrebovania takýchto suspenzných komponentov, ako je podprytá regály, pružiny, tiché bloky, nábojové ložiská, scruches, a tak ďalej.

- Zhoršenie pohodlia jazdy.

Kontrola tlmiča nárazov, ako skontrolovať pomocou tlmiča s vlastnými silami bez demontáže tlmiča nárazov

Je veľmi dôležité, aby táto metóda mohla skontrolovať len pomocný tlmič, a nie jeho výkon. Korešpondencia regálov technickými charakteristikami výrobcu je samostatná konverzácia.

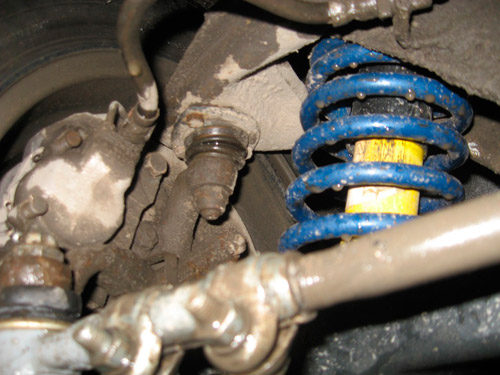

Môžete nezávisle kontrolovať pomocou tlmiča nárazov bez demontáže, môžete sa vizuálne - na diagnostiku, aby sa diagnostikovať prítomnosť mechanického poškodenia (t.j. dents) a dobroty tesnosti.

Ak sa netesnosti oleja a škvrny a škvrny sú pozorované na puzdre tlmiča nárazov, okamžite vytiahnite záver, že tesnenie boli opotrebované, čo indikuje vznik tlmiča nárazov.

Ľudia je názor, že olej "hmla" v prípade je porucha, ale nie. Po spustení tlmiča nárazov sa táto banka považuje za normálny fenomén.

Pri vykonávaní diagnózy tlmiča nárazov po demontáži je potrebné venovať osobitnú pozornosť tyči - nemala by to byť bundy, stopy korózie A, najmä deformácie.

Ako skontrolovať Tlmič pérovania pri výkone pomocou zariadenia s pohybom pohybu

Toto zariadenie je "Manual". Je pripojený k krídlu auta a senzor je umiestnený na zem. Telo vlnilo informácie. Súčasne sa do zariadenia zavádzajú výrobné parametre, ktoré sú rýchlosťou tlmiča nárazov. Výkon stojana je diagnostikovaný v percentuálnom pomere.

Skúška šoku (šok-test) Diagnostika tlmiča nárazov

Šokový test vyrobený na špeciálnom stánku. Kolesá osi by mali byť zdvihnutí a poklesli. Počítač registruje koeficient útlmu rečových oscilácií.

Expresná diagnostika tlmiča nárazov

Expresná diagnostika poskytuje ostré brzdenie. Vykonáva sa na stojane so špeciálnymi platformami. Súčasne sa kontroluje brzdový systém. Auto musí vstúpiť do plošiny a brzdiť ostro. Výkyvy karosérie vozidla sú fixované, ako aj zaťaženie snímačov platformy. Hoci presnosť tejto metódy ponecháva veľa, aby bola žiaduca.

Kontrola zaťaženia tlmiča tlmiča amplitúdy-rezonancie

Kontrola tlmičov amplitúdy rezonančná metóda je založená na analýze amplitúdy (to znamená, že hodnoty pohybu) plošiny s kolesom vozidla namontované. Platforma je hlásená osciláciou, ktorých frekvencia je asi 16 Hz. Keďže údaje sú oslabené, oscilácie sa vyskytujú rezonancia - zvýšenie amplitúdy oscilácií, keď frekvencia kolísania plošiny a vlastnej frekvencie suspenzie vozidla. Väčšie hodnoty amplitúdy dosahuje, tým horšie uhasí oscilácie tlmiča nárazov. Potom stojan porovnáva výsledky merania s referenčnými údajmi, po ktorých vydáva záver o výkone tlmiča nárazov.

Nové tlmiče tlmiča, ako skontrolovať tlmič nárazov v mieste nákupu od predávajúceho

- Vonkajšia, vizuálna kontrola. Skontrolujte označenie. Musí sa zhodovať s katalógom výrobcu. Ďalej musíte skontrolovať tlmič na prítomnosť rôznych mechanických poškodení žľabov, puzdra, tyče a tak ďalej. Skontrolujte závitové pripojenia. Samozrejme, nemali by existovať žiadne inklúzie ropy.

- Kontrola geometrického súladu. Potrebujete strmeň a pravítko. Je potrebné skontrolovať dĺžku v stavovom stave, priemer tyče a pohybovať sa (orientovať alebo na odporúčanie výrobcu, alebo odchýliť sa od menovitej hodnoty - ± 5 mm).

- Kontrola výkonu tlmiča nárazov. Jedna trubica sa kontrolujú bez predchádzajúcej prípravy. Mali by byť stlačené a natiahnuté asi 3-5 krát. Tyč sa musí hladko pohybovať bez ostrých joltov a rušení s rovnakým úsilím. Okrem toho by nemala existovať cudzia creak a hluk, okrem prirodzeného "návrhu", ktorý je výsledkom toku tekutiny vo vnútri stojana. Dual-potrubia musí byť pripravené niekoľkokrát (3-5) čerpať, umiestnené vertikálne, potom, čo neotáča tlmič.

Tipy Prof.

Diagnostikovať problémy, ktoré sú spojené s prácou tlmičov nárazov, je veľmi jednoduché - auto je výrazne pretrepávajúce, keď zasiahne hrbole, je počuť charakteristické poklepanie. Hlavným problémom spojeným s príchodom tohto zariadenia do Disrepair je, že tento proces sa vyskytuje postupne (výnimka je plynové a olejové tlmiče, ktoré sú spôsobené jeho konštrukciou, sú schopné okamžite zlyhať). Motorista sa teda môže prispôsobiť takémuto správaniu stroja a nie ponáhľať na opravu. Medzitým sa však opotrebovanie pneumatík a brzdná dráha zvyšuje, riadenie je horšie. Môže sa vám zdať, že ide o malé veci, ale na druhej strane, v núdzových prípadoch, porucha tlmočník môže významne ovplyvniť ich výsledok.

Stojí za zmienku, že v doprave, ktorý je vybavený elektronickými brzdovými systémami (EBD, ABS, a tak ďalej), chybné tlmiče nebudú zriedkavo viesť k zlyhaniam zlyhania.

Súvisiace materiály

- Sporák 2110, Zlé teplé sporák 2110, VZ 2110 Vykurovací systém, Oprava vykurovacieho systému Vaz 2110 s vlastnými rukami

- VAZ 2114 sporák s studeným vzduchom, sporákom 2114, zlé teplé sporák Vaz 2114, Zariadenie a opravy vykurovania VZ 2114 Do-it-yourself, odstránenie sporák VaZ 2114

- Ako subdominizovať auto. Ako dať zdvihák. Typy konektorov pre autá.

- VZ 2109 FUSE BLOK, VAZ 2109 FUSE BLOCK Karburátor, Vaz 2109 Poistkový blok Injektor, Old VAZ 2109 Poistkový blok, Vaz 2109 Poistkový blok, VIS FUSE BLOK 2109

- Katalyzátor výfukového plynu, chybný katalyzátor, plusy a nevýhody katalyzátora, ako zmeniť katalyzátor pre lietadlo

- Sporák Fúka studený vzduch VZ 2114, zle fúkanie sporák Vaz 2114, prečo zle fúkané sporák 2114

- Ako zistiť majiteľ auta podľa počtu jeho auta, skontrolujte auto podľa počtu dopravných policajných strojov, skontrolujte auto štátom číslo auta zadarmo

- Ako si vybrať použité pneumatiky, Užitočné tipy

- Zimné auto cesty, tlak v pneumatikách osobných automobilov v zime, dobrá batéria pre auto v zime, či sa vozidlo zahreje v zime

- V zime je auto zle spustené. Ako urobiť auto v zime, musíte zahriať auto v zime, užitočné tipy

- Stroje na spotrebu paliva, najhospodárnejšia spotreba automobilov

- Pneumatiky značky pre osobné automobily, označovanie automobilových pneumatík, zvyškový osobné auto pneumatík ochranca, ako si vybrať pneumatiku na značke automobilov, auto pneumatiky

- Pracovná prevodovka, mechanická prevodovka spojka, jazda s manuálnou prevodovkou, užitočné tipy

- Zadný nosník PEUGEOT 206 Sedan, Zadné svetlo PEUGEOT 206. Zadný lúč PEUGEOT 206 Porucha, Oprava zadného lúča PEUGEOT 206

- Dieselové palivo v zime, prísada pre nafty v zime, ako si vybrať najlepšie dieselové palivo

- Diesel Zima sa nespustí. Ako začať diesel v zime, vykurovanie nafty v zime.

- Japonské pneumatiky Bridgestone, Winter Studded Bridgestone pneumatiky, Bridgestone pneumatiky značky

- Označenie pneumatiky dekódovanie osobných automobilov, označovacích kolies, ako si vybrať správne pneumatiky na diskoch

- Dieselový motor v zime, spustenie dieselového motora v zime, aký olej vyplňte dieselový motor v zime, užitočné tipy

- LED podsvietenie automobilu, podsvietenie spodnej časti vozidla, podsvietenie nôh v aute, podsvietenie vo dverách vozidla, podsvietenie vozidla je v poriadku

- Obnovené pneumatiky, autobusová pneumatika, obnovená ochranca pneumatík, môžem ich použiť

- Vyberte si zimné pneumatiky, ktoré sú zimnými pneumatikami, ktorým by mal byť tlak v zimných pneumatikách označený zimnými pneumatikami, ako si vybrať správne zimné pneumatiky, najlepšie zimné pneumatiky 2019

- Riadiaca železničná koľajnica, Klopenie riadiaceho stojana, Dôvody na knock a opravy regálu riadenia

- Automatické pneumatiky, súpravu na opravu bezdušových pneumatík, opravu pneumatiky bez dela

- Ruské pneumatiky, ruské pneumatiky zimné, ruské pneumatiky pre všetky sezóny, pneumatiky Voronezh Amtel, pneumatiky "Matador Omsk Tire", KAMA-pneumatiky sú autobusom svetovej triedy

- Ako otvoriť auto bez kľúča. Stratil kľúč z auta, čo robiť, kľúč z auta vnútri auta

- Tiché pneumatiky, tiché zimné pneumatiky, pokojný autobus, ktorý pneumatiky vybrať, prehľad pneumatík

- Pneumatiky a bezpečnosť, bezpečnosť autobusu, prečo je potrebné neustále monitorovať pneumatiky

- Pravidlá bezpečnej jazdy automobilu v daždi a Slush, bezpečné riadenie vozidla pre začiatočníkov

- RUST CONVERTER, ktorý je lepší pre automobily, RUSTOVÉ CONNERTERS, KTORÉ SA ZVÝŠENIE AKO POUŽÍVAŤ RUSTO

- Leštenie tela auta si to urobí sám, ako si vybrať leštiacu pastu, užitočné tipy

- Trvanlivosť motora, životnosť motora, ako rozšíriť životnosť motora

- Zaklopať v aute. Zaklopať pri pohybe auta. Čo môže zaklopať v aute. Ako určiť príčinu klepania.

- ABS CAR, Čo je ABS Car, ABS Systémová porucha, ABS Diagnostics

- Predbiehanie auta, keď môžete začať predbiehať auto, pravidlá dopravných pravidiel

- Palivové čerpadlo VZ 2110, VAZ 2110 Schéma čerpacej stanice, VZ 2110 Palivové čerpadlo, Vaz 2110 Oprava čerpacej stanice,

- Automobilové antény pre rádio, automobilové antény zariadenie, auto anténa

- Predné odpruženie Kalina, Zariadenie predné odpruženie Kalina, zaklopať v prednej záveske Kalina, Oprava predného odpruženia Kalina

- Olej na tlmič, najlepšie tlmiče oleja, čerpacie tlmiče oleja, ako správne čerpať Tlmič pérovania oleja

- Poruchy spojky, dotýka sa spojky, spôsobuje poruchu spojky, ako eliminovať

Pripomienka