O cinto do mecanismo de distribuição de gás é um atributo indispensável para a maioria dos veículos modernos, incluindo o carro Chevrolet Lacetti. Apesar da excelente simplicidade, este é um detalhe bastante importante para o motor de combustão interna. Substituindo o cinto de tempo no Chevrolet Lacetti - O evento é bastante demorado, mas é completamente simples, se você agir exatamente abaixo das instruções fornecidas.

Contente

- Cinto de tempo, quais tarefas fazem o cinto de tempo

- Cinto de tempo, como funciona e de que material

- Quantas vezes altera o cinto de tempo

- Quanto trocar o cinto de tempo, que sinais falam sobre a necessidade de substituir o cinto de tempo

- Quebrou o cinto de tempo, que lidera um desses

- Cinto de tempo, por que a substituição do cinto é melhor fazer no conjunto

- Ferramentas, luminárias, consumíveis

- Técnica de segurança

- Substituindo o cinto de tempo Chevrolet Lacetti, passo a passo

- Dicas Profi, como verificar a tensão do cinto de tempo

Cinto de tempo, quais tarefas fazem o cinto de tempo

A tarefa é que o eixo de cames girou a uma velocidade, exatamente a metade idêntica do volume de negócios do virabrequim. Meio século atrás, a unidade de cadeia do GRM foi usada na indústria automotiva, e todas as tentativas de adaptar o cinto para isso foram mal-entendidos. Muito tempo passou antes da unidade de correia começar a dominar. Mas ele tem várias vantagens significativas - simplificando o design, baixo ruído e uma diminuição na massa da unidade de energia.

Hoje, os fabricantes preferem instalar drives de correia em seus carros. Mas é impossível dizer inequivocamente que a corrente é pior que o cinto. A unidade de corrente também tem sua vantagem - durabilidade, correlacionada com a duração do próprio motor. Portanto, mesmo em nosso tempo, algumas empresas de fabricação impedem sua escolha no mecanismo de cadeia. Além disso, esses motores são geralmente equipados com tensores automáticos. A vida útil do cinturão ordinário é muito raramente excede 60 mil quilômetros, e a simplicidade do design implica a necessidade de serviço permanente - pull-up, substituição, controle sobre o status do cinto.

Cinto de tempo, como funciona e de que material

Para que a correia de tempo funcione de forma confiável, as seguintes condições devem ser observadas - o estado ideal das polias e rolos ao longo do qual a correia é movida, a tensão correta da correia, sua proteção absoluta contra o óleo e a sujeira. O design do cinto é bastante simples e algo se assemelha a um pneu de carro.

Portanto, a maioria das empresas que se especializam na produção de pneus também produzem cintos. A base da correia de tempo - cordão - o plexo de fios duráveis \u200b\u200bda fibra de vidro. Os cordões internos são dentes de materiais resistentes ao desgaste (como regra, nylon), e fora dele protege a camada de borracha, a espessura dos quais é cerca de cinco milímetros. O design dos cintos é bastante diversificado. Pode diferir na largura do cinto, número e passo dos dentes, bem como seu perfil (há cerca de vinte tipos de perfis de dentes).

Quantas vezes altera o cinto de tempo

A substituição da correia de tempo no Chevrolet Lacetti, de acordo com os regulamentos de manutenção, é necessário conduzir a cada 60.000 quilômetros de milhagem. No entanto, a maioria dos especialistas recomenda reduzir a mudança no período de substituição devido a condições de operação complexas. Quanto à verificação do estado do cinto, então no carro Chevrolet Lacetta deve ser realizado a cada 30 mil quilômetros.

Quanto trocar o cinto de tempo, que sinais falam sobre a necessidade de substituir o cinto de tempo

- Vestindo material. O cinto de tempo é capaz de se desgastar da mesma maneira que, por exemplo, pneu. Se o material da correia estiver desgastado, ele pode ocorrer para abri-lo ou escorregar. Especialmente muitas vezes isso acontece em grandes cargas no motor do motor. Por exemplo, ao traçar um reboque ou reboque, bem como no clima úmido.

- Abrasão de cinto. Isso acontece, por via de regra, com o desvio da polia e o rolo de tensor da posição traseira, bem como quando o mau funcionamento do rolamento e a temperatura elevada. Em caso de inspeção, você pode notar o desgaste dos dentes da correia - sua base tecidual (fibras de tecido dilatadas e textura desigual).

- Desapego ou rachaduras. Esse recurso de desernidade é óbvio. É necessário explorar a superfície traseira e frontal da correia. A presença de rachaduras, especialmente se houver muitos deles, indica um forte desgastado.

- O endurecimento da superfície oposta da correia dentada é a superfície oposta da correia é dura, não elástica e glitter. Neste caso, o cinto torna-se provocável, como resultado do qual não fornece mais o contato desejado com a polia.

- Alongamento. O desgaste material é capaz de liderar um forte alongamento de correia, como resultado do qual o rolo de tensão se move além dos limites permissíveis. Isso reduz a rigidez e a tensão total da correia e, consequentemente, o desempenho geral do mecanismo.

- Desvio da posição designada. Esse recurso indica que os elementos internos do rolo de tensionamento estão bastante próximos da quebra. Se o rolo falhar, ele levará ao aumento do ruído, temperatura e vibrações.

Quebrou o cinto de tempo, que lidera um desses

O acidente do cinto de tempo pode implicar uma massa de consequências desagradáveis \u200b\u200bque são diferentes, variando da necessidade de substituir a correia de tempo e restaurar o mecanismo de distribuição de gás e a revisão do motor.

A situação mais difícil é quando a válvula é curvada como resultado da pausa da correia. Isso é explicado simplesmente. A lacuna pode acontecer no período em que as válvulas caíram para a injeção de combustível ou a liberação de gases. Ao mesmo tempo, o movimento de pistões nos cilindros ainda continua e eles são capazes de atingi-los de toda a força. Neste caso, a "reunião" pode acabar muito mal.

Estimar o grau de dano só pode ser avaliado após desmantelar a cabeça do motor e estimar o estado do sistema e válvulas do pistão. Deve-se notar que o defeito da válvula não pode ver imediatamente - para diagnóstico requer equipamento especial.

Cinto de tempo, por que a substituição do cinto é melhor fazer no conjunto

Para evitar problemas no futuro, a substituição do cinto de tempo é desejável para produzir junto com bombas e rolos. Esta não é uma ação obrigatória, no entanto, se houver fundos adicionais, é melhor não ser preguiçoso porque afetará a eficiência do novo cinto de tempo.

Além disso, para cumprir a substituição, você terá que desmontar totalmente todos os componentes deste equipamento, incluindo a bomba com rolos. Assim, a substituição de consumíveis O custo deste procedimento não aumentará muito, e não levará muito tempo, mas aumentará a vida útil do agregado substituído.

Ferramentas, luminárias, consumíveis

- Cabeça em "10", "12", "14", "17", "32".

- Ênfase ajustável.

- Hexágono em "5".

- A chave para "41".

- PASSATIA.

Técnica de segurança

É impossível trabalhar sob o veículo se ele estiver postado apenas no jack. Como seguro em obrigatório, use a estação de condição de fábrica. É proibido pendurar o carro em dois ou mais tomadas. Para proteger suas mãos de contusões e cortes com operações "poder", você deve trabalhar em luvas.

Substituindo o cinto de tempo Chevrolet Lacetti, passo a passo

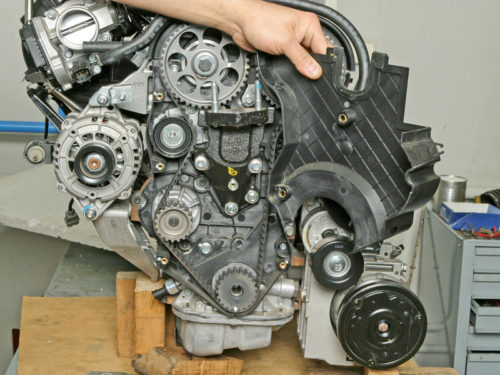

- Abra o capô e desmonte um revestimento decorativo com um motor, para o qual você precisa desparafusar quatro porcas.

- Por conveniência, desmonte a caixa do filtro de ar. Para fazer isso, com a cobertura do filtro de ar, nós desaparafusamos os quatro parafusos, bem como a camada de bocal de ar. Nós desmantelamos a tampa e o filtro de ar. Para remover o próprio filtro, desaparafuse mais dois parafusos.

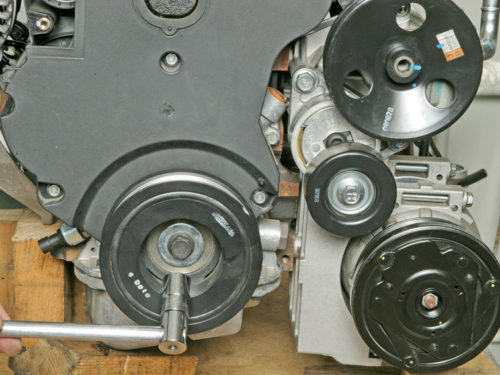

- Agora remova a correia de acionamento - Puxe o rolo da unidade usando a chave para "17" e desmonte o cinto das polias. Em seguida, você deve desparafusar dois parafusos e remover a tampa superior da tampa de tempo.

- Fazemos a remoção da roda dianteira direita e a antera lateral do motor, que é anexada a três pistões e dois parafusos.

- Nós desaparafusamos a polia do virabrequim, para a qual você corrige o volante usando uma chave de fenda enorme através da janela de visualização. Então, com um soldador e cabeça em "17" nós desaparafuse e desmantelamos a polia do virabrequim.

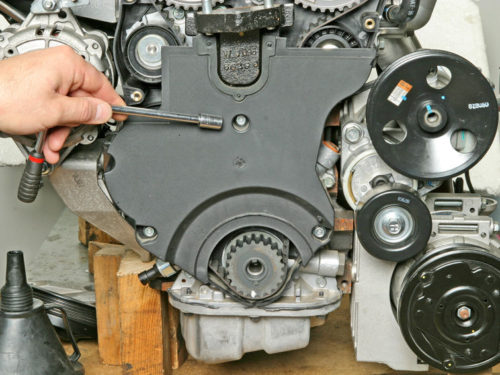

- Você também deve remover a tampa inferior da correia de temporização, que é anexada por três engrenagens.

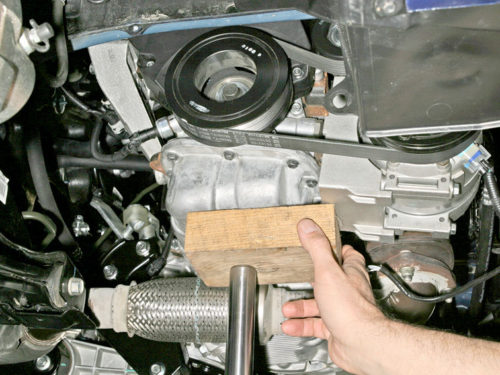

- O próximo passo é remover o suporte do motor, para o que você precisa instalar um conector adicional para uma unidade de energia sob o palete. Em seguida, nós desaparafusamos 3 porcas e 1 parafuso usando a chave para "14" e desmontar o suporte OB.

- Nós desaparafusamos os quatro parafusos ao redor do perímetro do suporte de suporte e removendo o suporte.

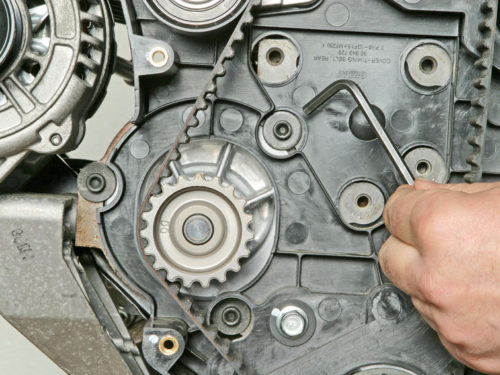

- Além disso, em todas as polias, definimos as tags de temporização. Na polia do virabrequim, estará abaixo.

- Para a conveniência da rotação do virabrequim, aperte o parafuso de polia de volta.

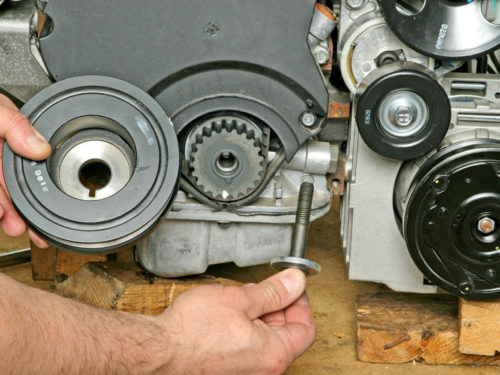

- Agora prossiga para substituir o cinto de tempo. Usando a chave para "14", nós desaparafusamos o rolo parasitário, que está localizado à direita e desmonta o cinto, após o que nós desaparafusamos o tensor de rolos, que é anexado por três parafusos.

- Antes de montar o cinto, verifique as tags, porque depois de remover eles poderiam ser derrubados.

- Quando permanece apenas para usar um cinto na bomba, mova o tensor de rolos, após o que é até o final da correia e verifique a instalação dos rótulos.

- Em seguida, role o virabrequim no sentido horário em uma ou duas voltas e verifique as etiquetas novamente.

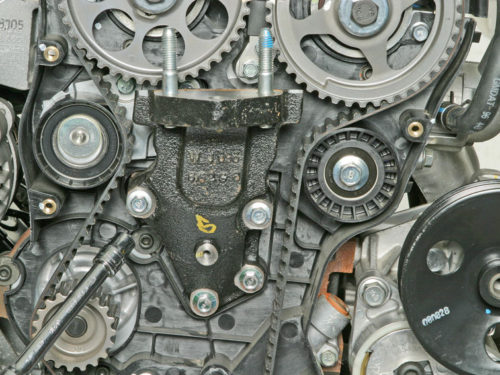

Dicas Profi, como verificar a tensão do cinto de tempo

Para verificar a tensão do cinto de tempo, gire o virabrequim duas a três vezes no sentido horário e olhe para os dentes do rolo do tensor. É necessário que eles estejam em frente uns aos outros - mais-menos alguns milímetros. Se as leituras diferem, você terá que ajustar a tensão da correia usando as bombas.

Materiais relacionados

- Fogão 2110, fogão quente ruim 2110, Vaz 2110 sistema de aquecimento, reparando o sistema de aquecimento Vaz 2110 com suas próprias mãos

- Vaz 2114 fogão sopra com ar frio, fogão 2114, fogão morno ruim Vaz 2114, dispositivo e reparação de aquecimento Vaz 2114 do-it-você mesmo, removendo o fogão Vaz 2114

- Como subdominar o carro. Como colocar um jack. Tipos de macacos para carros.

- Vaz 2109 Fusível Bloco, Vaz 2109 Fusível Fusível Carburador, Vaz 2109 Fusível Injetor De Bloco, Old Vaz 2109 Fusível Bloco, Vaz 2109 Fusível Bloco, Vaz Fuse Block 2109

- Catalisador de gás de exaustão do carro, catalisador defeituoso, vantagens e contras do catalisador, como mudar o catalisador no planeencitel

- Fogão soprando a ar frio Vaz 2114, mal soprando o fogão Vaz 2114, por que mal soprando o fogão Vaz 2114

- Como descobrir o dono do carro pelo número de seu carro, verifique o carro pelo número da máquina de polícia de tráfego, verifique o carro pelo número do estado do carro de graça

- Como escolher pneus usados, dicas úteis

- Estrada de carro de inverno, pressão nos pneus de carro de passageiros no inverno, boa bateria para o carro no inverno, seja aquecer o carro no inverno

- No inverno, o carro é mal iniciado. Como fazer um carro no inverno, você precisa aquecer o carro no inverno, dicas úteis

- Máquinas de consumo de combustível econômico, o consumo de carro mais econômico

- Marcas de pneus para carros de passageiros, rotulagem de rotulagem de pneus de carro, protetor de pneu de carro de passageiros residual, como escolher um pneu em uma marca de carro, padrão de piso de pneu de carro

- Operação de transmissão de trabalho, trabalho mecânico de caixa de engrenagens, dirigindo com caixa de engrenagens manual, dicas úteis

- Feixe traseiro Peugeot 206 Sedan, dispositivo de feixe traseiro Peugeot 206. Feixe traseiro Peugeot 206 mau funcionamento, reparação do feixe traseiro Peugeot 206

- Combustível diesel no inverno, aditivo para combustível diesel no inverno, como escolher o melhor combustível diesel

- O inverno diesel não começa. Como começar a diesel no inverno, aquecimento a diesel no inverno.

- Pneus japoneses Bridgestone, inverno cravejado de pneus Bridgestone, marca de pneus Bridgestone

- Decodificação de marcação de pneus para carros de passageiros, rotulando rodas, como escolher os pneus certos nos discos

- Motor diesel no inverno, lançamento do motor diesel no inverno, que óleo para preencher um motor diesel no inverno, dicas úteis

- Luz de fundo do carro, a luz de fundo do fundo do carro, a luz de fundo das pernas no carro, a luz de fundo na porta do carro, a luz de fundo do carro é bom

- Pneus recuperados, pneu de ônibus, protetor de pneu restaurado, posso usá-los

- Escolha pneus de inverno, que é um pneu de inverno, que a pressão nos pneus de inverno deve ser marcada com pneus de inverno, como escolher os pneus de inverno certos, os melhores pneus de inverno 2019

- Trilho ferroviário de direção, bater de direção, razões para a batida e reparação do rack de direção fazem você mesmo

- Pneus de carro de camboque, um conjunto para reparação de pneus sem tubulação, reparação do pneu sem canhão, faça você mesmo

- Pneus russos, pneus russos Inverno, pneus russos de todas as estações, Voronezh Amtel pneus, pneus "matador omsk pneu", Kama-pneus são ônibus de classe mundial

- Como abrir um carro sem uma chave. Perdeu a chave do carro O que fazer, a chave do carro dentro do carro

- Pneus silenciosos, pneus de inverno silenciosos, ônibus tranquilo, que pneus para escolher, visão geral pneus

- Pneus e segurança, segurança do ônibus, por que é necessário monitorar constantemente pneus de carro

- Regras de condução segura do carro na chuva e lama, dirigindo seguro do carro para iniciantes

- Conversor de ferrugem que é melhor para carros, conversores de ferrugem para escolher como usar transdutor de ferrugem, profissionais

- Polimento do corpo do carro faz você mesmo, como escolher uma pasta de polimento, dicas úteis

- Durabilidade do motor, vida do motor, como estender a vida do motor

- Bater no carro. Bata ao mover o carro. O que pode bater no carro. Como determinar a causa da batida.

- Carro ABS, o que é carro ABS, mau funcionamento do sistema ABS, diagnósticos ABS

- Superando um carro quando você pode começar a ultrapassar um carro, regras de regras de trânsito

- Bomba de combustível VAZ 2110, esquema de posto de gasolina Vaz 2110, dispositivo de bomba de combustível VAZ 2110, conserto de posto de gasolina VAZ 2110,

- Antenas automotivas para rádio, dispositivo de antena automotiva, antena de carro você mesmo

- Suspensão dianteira Kalina, Suspensão dianteira do dispositivo Kalina, Knock in Front Suspension Kalina, Reparação de Suspensão Frente Kalina

- Óleo absorvedor de choque, melhor amortecedores de petróleo, bombeamento de amortecedores de óleo, como bombear adequadamente o amortecedor de óleo

- Enfunções de embreagem, toque embreagem, faz com que um mau funcionamento da embreagem, como eliminar

Comentários