Lorsque vous conduisez sur une voiture, il est assez souvent possible d'observer la survenue du bourdonnement caractéristique, qui peut le surmener au fil du temps. De plus, cela change en fonction de l'état de la surface de la route. Sur une bonne route - le bourdon disparaît ou diminue, il peut donc sembler qu'il n'y a pas besoin de réparer, mais dès que les roues vont à une mauvaise route - le Hum apparaît à nouveau. De plus, à grande vitesse, vous pouvez entendre une relief spécifique. La raison de l'apparition de ces symptômes, en règle générale, est la faute du roulement du moyeu. Il convient de noter que si vous ne remplacez pas de roulement bourdonnant de manière en temps opportun, alors lorsque vous conduisez, cela peut être confipé, ce qui est extrêmement dangereux et représente une menace pour la vie, avec la moindre manifestation des symptômes de dysfonctionnement décrit ci-dessus, Il devrait être remplacé par le roulement de moyeu dès que possible. À ce sujet plus loin dans l'article.

Teneur

- Hub de roulement, quelles tâches il effectue

- Roulement à rouleaux, dispositif, avantages et inconvénients

- Roulement diagonal, dispositif, avantages et inconvénients

- Le moment du resserrement des roulements, ce qu'il est et comme un couple du roulement affecte la durée de fonctionnement

- Le roulement de moyeu est défectueux, signes de casse

- Outils et appareils de remplacement du roulement de moyeu, de la sécurité

- Remplacement du roulement de la roue avant, des instructions étape par étape

- Remplacement du roulement de roue arrière, instruction étape par étape

- Conseils Profi, comment faire un travail correctement, quel lubrifiant vaut mieux utiliser pour roulement

Hub de roulement, quelles tâches il effectue

Le port est un mécanisme qui supporte une partie du support. Il est capable de maintenir l'arbre, l'axe ou tout autre élément, mais dans tous les cas, son objectif principal est la fixation de l'arbre dans l'espace, ce qui garantit sa distribution ou sa rotation gratuite. La deuxième fonction du roulement de moyeu est la perception de la charge mécanique, ainsi que de son transfert à d'autres éléments.

Le roulement de moyeu est un mécanisme qui est un roulement roulant. Il fournit une rotation lisse de la roue autour de l'axe. Ces roulements sont une rangée et une double rangée, ainsi que des types ouverts et fermés. Ils sont utilisés dans les passagers et les camions. Les roulements de roue pour les roues avant et arrière diffèrent considérablement les uns des autres.

Les roulements de moyeu de voitures sont constamment soumis à des charges extrêmes. Il inclut les différences de température élevées, l'impact environnemental, la formation de charges de choc lorsqu'ils entrent dans les fosses, la direction, les freins, le lecteur. Il convient de noter que la réaction ne doit pas empêcher la rotation de la roue, qui doit tourner avec un frottement minimal et un bruit admissible.

Roulement à rouleaux, dispositif, avantages et inconvénients

Les roulements à rouleaux sont très sensibles à l'installation, qui, s'il est mal effectué de manière incorrecte, est capable de supprimer instantanément la pièce dans l'ordre. Les débutants qui ne savent pas que cette fonctionnalité des roulements à roues routiers trompent souvent des ouvriers sans scrupules de la STO, qui produisent le remplacement de cet élément à la main d'ambulance et mal.

Roulement diagonal, dispositif, avantages et inconvénients

Les roulements diagonaux sont capables de résister aux charges lourdes et ont une excellente résistance à l'usure.

Cependant, leur travail, comme les roulements à roulettes, dépend de la bonne installation (forte resserrement), sinon ils échoueront.

Le moment du resserrement des roulements, ce qu'il est et comme un couple du roulement affecte la durée de fonctionnement

Le moment du resserrement des roulements est un événement qui devrait être fait précisément conformément aux recommandations du fabricant du véhicule. Comme déjà mentionné, le paramètre incorrect de la roulement entraîne sa panne.

Si plus tôt pour ajuster les capacités spéciales requises, ainsi que la présence d'outils spéciaux difficiles à trouver à cette époque, il n'y a pas de problèmes à cet égard. Maintenant, chaque propriétaire de la voiture peut acheter la boîte à outils nécessaire et obtenir des données vous permettant de contrôler indépendamment l'état des roulements et d'autres éléments de la voiture.

Le roulement de moyeu est défectueux, signes de casse

Les principaux signes du dysfonctionnement du porte-hub de voiture sont les suivants:

- Fort bourdonnement ou bruit qui est entendu du véhicule derrière le véhicule. Si le moyeu de roulement est défectueux, le bruit devient plus en tournant.

- L'apparence de la barreaux dans la roue arrière, accompagnée de bruit ou de taraudage.

Outils et appareils de remplacement du roulement de moyeu, de la sécurité

- Extracteur spécial.

- Marteau.

- Pinces pour démonter une cueillette.

- Clé sur 17.

- Un hexagone clé sur 10.

- Tournevis.

- Ciseau.

Avant le remplacement, n'oubliez pas de mettre les barres anti-tartre sous les roues arrière et sous le corps - focus.

Remplacement du roulement de la roue avant, des instructions étape par étape

- Affaiblissement des boulons de fixation de la roue avant.

- Rouler la nulle.

- Ensuite, soulevez la voiture à la prise et démanteler la roue avant.

- Nous trouvons une noix qui fixe la pointe de la direction, puis la dévisse.

- À l'aide d'un extracteur, une pointe de direction est enfoncée.

- Prenez le dernier de la crémaillère avant.

- Nous trouvons et retirons les deux capuchons métalliques, la fixation de l'étrier étrier.

- Dévisser les boulons d'étrier.

- Pour que l'étrier n'interfère pas, retirez-le, après quoi nous sommes suspendus sur le fil.

- Puis dévisser la balle du support de balle.

- Connaître le support de balle.

- Retirez le disque de frein.

- Maintenant, vous devriez dévisser la noix du moyeu.

- Sous la capuche affaiblir les deux noix tenant un rack sur une tasse.

- Nous retournons à la voiture et retirons le levier du support de balle.

- Ensuite, tirez le rack de la scène, cependant, il doit être utilisé ici pour ne pas tirer la tige d'entraînement.

- Maintenant, retirez complètement le rack.

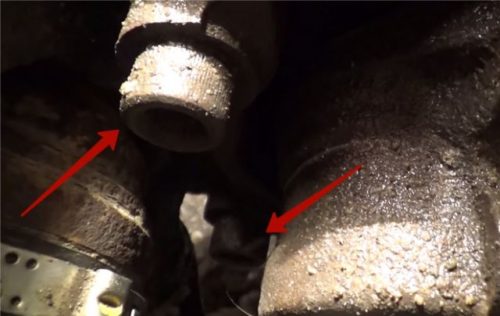

- Lorsque le moyeu de roulement s'étend, il y a en fait une bague intérieure.

- Le roulement est assommé et la bague coupée sur la meuleuse.

- Le nouvel élément est doucement entraîné ou inséré en place.

Remplacement du roulement de roue arrière, instruction étape par étape

Le remplacement du roulement de moyeu arrière est fabriqué de la même manière:

- Retirez la roue arrière.

- Je suis mont sous le corps du corps.

- Nous dévissions les boulons de l'axe de moyeu et du tambour. Si nécessaire, Splash WD-40.

- Retirez le tambour de frein.

- Nous démantons le capuchon du moyeu.

- Nous démantons la noix, à travers laquelle le bouchon est habillé. Il faut y accéder, après quoi tirer la pince.

- Retirez de l'axe la bague intérieure du roulement avec les déménagements ou retirez simplement l'axe en dévissant quatre écrous du côté inverse.

- Avec un tournevis, nous retirons le clip et avec l'aide d'un ciseau, frappez soigneusement la bague intérieure de l'axe.

- Nous vous prescrirons une nouvelle roulement avec l'aide d'un ancien climat.

- Après l'assemblage, nous traînons la noix, appliquant un certain effort.

Après l'opération, il devrait conduire trois ou quatre jours. Ensuite, vous devez retirer la noix pour retirer le jeu.

Conseils Profi, comment faire un travail correctement, quel lubrifiant vaut mieux utiliser pour roulement

- Il est souhaitable de remplacer les roulements sur les roues arrière ou avant, que la valeur y ait la partie.

- Choisissez le bon lubrifiant sous roulements.

- Il est impossible de battre le marteau à droite sur le roulement, il est nécessaire de le faire avec une tablette en bois.

- Dans les nœud hub, il est impossible de mettre un écart, car à l'usine, ils ont été collectés en tenant compte des lacunes.

- Lors du remplacement du roulement, veillez à vérifier l'état de l'axe et du boîtier.

- Vous ne pouvez pas régler ou déplacer le joint sur les nœuds de roue.

Matériel connexe

- Cuisinière 2110, poêle grave 2110, système de chauffage VAZ 2110, réparation du système de chauffage VAZ 2110 avec leurs propres mains

- VAZ 2114 Cuisinière souffle avec air froid, poêle 2114, mauvais poêle chaud VAZ 2114, appareil et réparation du chauffage VAZ 2114 DO-IT-IT-IT-YOUS, Retrait du poêle VAZ 2114

- Comment sous-dominer la voiture. Comment mettre une prise. Types de vérins pour voitures.

- Vaz 2109 Bloc de fusible, Vaz 2109 Carburateur de fusibles, Vaz 2109 Injecteur de blocs de fusibles, Bloc de fusible Vaz 2109, bloc de fusible VAZ 2109, bloc de fusible VAZ 2109

- Catalyseur à gaz d'échappement de voiture, catalyseur défectueux, plus et inconvénients du catalyseur, comment changer le catalyseur sur le planencitel

- Poêle soufflant à l'air froid Vaz 2114, soufflant mal la cuisinière Vaz 2114, pourquoi mal souffler le poêle Vaz 2114

- Comment découvrir le propriétaire de la voiture par le numéro de sa voiture, vérifiez la voiture par le numéro de la machine de police de la circulation, vérifiez gratuitement la voiture du numéro de la voiture.

- Comment choisir des pneus usés, des conseils utiles

- Route de la voiture d'hiver, pression dans les pneus de voiture de tourisme en hiver, bonne batterie pour la voiture en hiver, que ce soit pour réchauffer la voiture en hiver

- En hiver, la voiture est mal commencée. Comment faire une voiture en hiver, avez-vous besoin de réchauffer la voiture en hiver, des conseils utiles

- Machines à consommation de carburant économiques, la consommation de voitures la plus économique

- Marques de pneus pour voitures de tourisme, étiquetage de l'étiquetage des pneumatiques de voiture, protecteur de pneus de voiture de tourisme résiduel, comment choisir un pneu sur une marque de voiture, motif de la bande de roulement des pneus de voiture

- Fonctionnement de transmission de travail, travaux d'embrayage de boîte de vitesses mécaniques, conduite avec boîte de vitesses manuelle, astuces utiles

- Berline de faisceau arrière Peugeot 206 Dispositif de faisceau arrière Peugeot 206. Basse arrière Peugeot 206 Dysfonctionnement, Réparation du faisceau arrière Peugeot 206

- Carburant diesel en hiver, additif pour le carburant diesel en hiver, comment choisir le meilleur carburant diesel

- L'hiver du diesel ne commence pas. Comment commencer le diesel en hiver, chauffer du diesel en hiver.

- Pneus Bridgestone japonais, pneus Bridgestone à clous d'hiver, marque de pneus Bridgestone

- Décodage de marquage des pneus pour les voitures de tourisme, étiquetage roues, comment choisir les bons pneus sur les disques

- Moteur diesel en hiver, lancement du moteur diesel en hiver, quelle huile remplir un moteur diesel en hiver, astuces utiles

- Rétro-éclairage de la voiture, le rétroéclairage du fond de la voiture, le rétroéclairage des jambes dans la voiture, le rétroéclairage dans la porte de la voiture, le rétroéclairage de la voiture va bien

- Pneus récupérés, pneu de bus, protecteur de pneu restauré, puis-je les utiliser

- Choisissez des pneus d'hiver, qui est un pneus d'hiver, que la pression des pneus hiver doit être marquée avec des pneus d'hiver, comment choisir les bons pneus d'hiver, les meilleurs pneus d'hiver 2019

- Rail ferroviaire de pilotage, frapper un porte-direction, raisons pour les raisons de la caisse et de la réparation du rack de direction le font vous-même

- Pneus de voiture Cameurs, un ensemble pour la réparation de pneus sans chambre à tubeless, réparation du pneu sans canon Fais-le vous-même

- Pneus russes, pneus russes hiver, pneus de la saison russe, pneus de Voronezh amtel, pneus "Matador omsk pneu", kama-pneus sont des bus de classe mondiale

- Comment ouvrir une voiture sans clé. Perdu la clé de la voiture quoi faire, la clé de la voiture à l'intérieur de la voiture

- Pneus silencieux, pneus hiver calmes, autobus cloutés silencieux, qui pneus à choisir, pneus d'ensemble des pneus

- Pneus et sécurité, sécurité du bus, pourquoi il est nécessaire de surveiller constamment des pneus de voiture

- Règles de conduite sûre de la voiture sous la pluie et la silhouette, une conduite sûre de la voiture pour les débutants

- Convertisseur de rouille qui est préférable pour les voitures, les convertisseurs de rouille pour choisir comment utiliser le transducteur de rouille, les professionnels

- Polissage du corps de la voiture Faites-le vous-même, comment choisir une pâte de polissage, des conseils utiles

- Durabilité du moteur, vie moteur, comment prolonger la durée de vie des moteurs

- Frapper dans la voiture. Frapper lors du déplacement de la voiture. Qu'est-ce qui peut frapper dans la voiture? Comment déterminer la cause du frappe.

- Voiture ABS, quelle est la voiture ABS, le dysfonctionnement du système ABS, les diagnostics ABS

- Dépasser une voiture lorsque vous pouvez commencer à dépasser une voiture, règles de règles de la circulation

- Pompe à carburant VAZ 2110, Schéma de station-service VAZ 2110, Dispositif de pompe à carburant VAZ 2110, réparation de la station d'essence VAZ 2110,

- Antennes automobiles pour radio, appareil d'antenne automobile, antenne de voiture le faire vous-même

- Suspension avant Kalina, dispositif suspension avant Kalina, frapper à la suspension avant Kalina, réparation de la suspension avant Kalina

- Huile d'amortisseur, meilleur amortisseur d'huile, pompage des amortisseurs d'huile, comment pomper correctement l'amortisseur d'huile

- Dysfonctionnements d'embrayage, touche l'embrayage, provoque un dysfonctionnement d'embrayage, comment éliminer

commentaires