Nedavno su vlasnici automobila imali mnogo puta tijekom cijelog životnog vijeka automobila za obavljanje malog ili motora remont. Danas vozači preferiraju automobilske marke na kojima se ne mogu montirati mehanizmi koji ne zahtijevaju sustavno popravak ili održavanje. Međutim, nažalost, svi agregati i čvorovi vozila istrošeni u isto vrijeme. Najčešće živjeli element automobila je motor koji ne uspijeva na prvom mjestu. O tome dalje u članku.

Sadržaj

- Auto motor, zašto ne uspije brže od samog stroja

- Uzroci trošenja motora

- Kako gorivo utječe na motor

- Ulje za ulje ulje poput ulja utječe na motor

- Loše rashladno sredstvo

- Filter ulja, zrak i gorivo - prljavi filter, kasna zamjena, jer utječe na motor

- Abrazivno trošenje dijelova motora, uzroci

- Način rada, utjecaj na trajnost motora

- Započnite i zagrijavanje motora, kako utječu na život motora

- Duge sranja, dobro ili loše

- Održavanje i pravovremeno popravak

- Dizajn rješenja jer utječu na trajnost motora

- SAVJETI PROS: Nadajmo gore navedeno

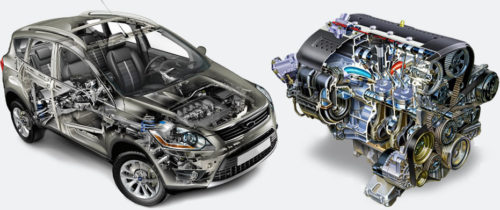

Auto motor, zašto ne uspije brže od samog stroja

Automobilski motor može brzo propustiti kao rezultat utjecaja na razne vanjske i unutarnje čimbenike, kao što je loša kvaliteta goriva ili ulja, ekstremni radni uvjeti i tako dalje.

Uzroci trošenja motora

U razlozima ubrzanog trošenja elektroenergetske jedinice uključuju:

- Neočekivana promjena ulja.

- Korištenje niskokvalitetnog ulja.

- Korištenje visokokvalitetnog goriva.

- Nezadovoljavajuće stanje goriva ili filtra zraka.

- Fino uklanjanje pogrešaka motora.

- Neispravan rad jedinice za napajanje.

- Prisutnost oštećenja proizvodnje.

Kako gorivo utječe na motor

Kvaliteta goriva je najvažniji čimbenik koji utječe na "kvalitetu vožnje" vozila i za rad motora. Strogi zahtjevi koji reguliraju emisije štetnih tvari strojevima su unaprijed određene nekim karakteristikama korištenim gorivom.

Značajke goriva koje utječu na rad motora:

- Isparavanje goriva.

- Prisutnost aromatskih ugljikovodika.

- Sadržaj vode ili alkohola u gorivu.

- Oktanski broj.

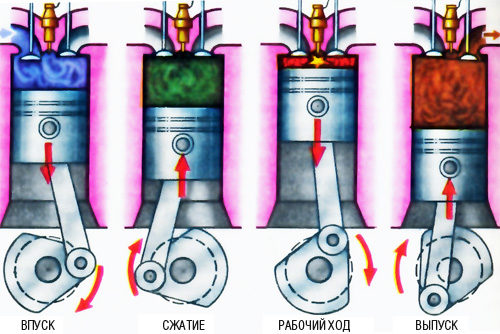

Isparavanje goriva karakterizira njegovu sposobnost da se presele u paru iz tekućeg stanja. Benzin ne gori u tekućem stanju, tako da treba ispariti prije ulaska u komoru za izgaranje. Budući da temperatura okoline utječe na rad motora, tada se u različito vrijeme koriste različite vrste goriva. S oštrim promjenom temperature zraka mogu postojati različite greške koje su zbog nedosljednosti goriva i vremenskih uvjeta.

Visoka evakuacija:

- Formiranje parnih čepova.

- Preopterećenje adsorbera pare faze.

- Raspodjela zlonamjernog pare.

Nisko isparavanje:

- Loša operacija motora u hladnom vremenu.

- Sporo zagrijavanje motora.

- Teško pokretanje hladnoće jedinice.

U pravilu, aromatski ugljikovodici se dodaju u gorivo za povećanje oktanskog broja. Kao rezultat njihove previsoke koncentracije u izgaranju, naslage čađe formiraju se na ulaznim ventilima, što je smanjenje snage motora, pogoršanje potrošnje goriva i povećanje ispušnih plinova štetnih komponenti.

Dodavanje alkohola u gorivo povećava oktanski broj i smanjuje emisije CO. Najčešći aditivi u obliku izopropilnog alkohola, metanola i etanola. Prekomjerna koncentracija alkohola u izgaranju je sposobna oštetiti komponente sustava za dovod goriva i pogoršati "kvalitetu vožnje" vozila.

Greške koje uzrokuju vodu u gorivu:

- Neujednačen rad motora u načinu mirovanja.

- Povećana potrošnja goriva.

- Ubrzanje ili trzanje tijekom ubrzanja.

- Teško pokretanje motora.

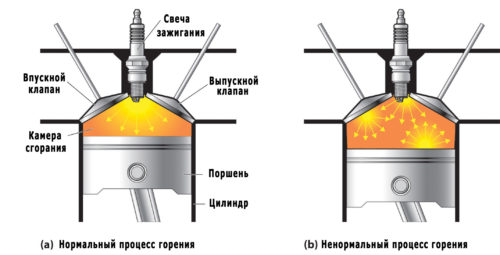

Oktanski broj unaprijed određuje sposobnost goriva kako bi se oduprijeti pojavi detonacije. Gorivo s velikim oktanskim brojem (na primjer, benzin AI-95) opire detonaciju od goriva s niskim oktanskim brojem (na primjer, benzin AI-92). Pojava detonacije smanjuje učinkovitost goriva i pogoršava rad jedinice za napajanje. Jačanje detonacije može ozbiljno oštetiti motor.

Ulje za ulje ulje poput ulja utječe na motor

Korištenje loših kvalitetnih ulja može napustiti ubrzano trošenje jedinice za napajanje. Ulje koje nema cijela svojstva nekretnina potrebnih za normalno mazivo elemenata nije u stanju spriječiti stvaranje skaliranja, kao i uništavanje radnih površina visoko napunjenih dijelova (turbopunjač ležajevi, košuljice radilice , klipne suknje, klipni prstenovi, mehanizam distribucije plina, i tako dalje. Povećao nagib loša kvaliteta maziva na pojavu smolastih sedimenata može dovesti do blokade naftnih kanala nego napustiti par trenja bez podmazivanja, što će uzrokovati njihovo brzo Nosite, ometanje i obrazovanje skaliranja. Ti su učinci mogući pri nanošenju maziva, koji u pogledu kvalitete kvalitete ne u skladu s ovom jedinicom za napajanje., Na primjer, ako umjesto preporučenog ulja primjenjuje jeftinije.

Loše rashladno sredstvo

Prilikom odabira tosole, potrebno je biti izuzetno pažljiv, jer korištenje sumnjivog ili loša rashladna tekućina nekoliko mjeseci može "ubiti" motor automobila. To će biti prethođeno uništavanjem tijela pumpe za vodu, cijev radijatora i glava bloka cilindra. Važno je reći da sva kršenja u radu sustava hlađenja i podmazivanja dovode do brzog trošenja komponenti i, posljedično, skupom i dugotrajnom popravku.

Filter ulja, zrak i gorivo - prljavi filter, kasna zamjena, jer utječe na motor

Povećanje resursa jedinice za napajanje također utječe na pružanje visokokvalitetnog pročišćavanja ulja, goriva i zraka, koji dolaze na motor. Zagađeni filtar ulja ne može očistiti ulje koje lako može prodrijeti kroz premosni ventil u motor. Onečišćenje goriva i zraka za filtriranje komponenata vodi do povećanja tlaka hidrauličkog, kao i za smanjenje snage agregata. U konačnici, komponenta filtriranja ne izdržava i rasprsnu, međutim, da je najtužnije, vlasnik automobila možda ni primijetio.

Abrazivno trošenje dijelova motora, uzroci

Svi gore navedeni čimbenici tijekom vremena dovode do najviše otežanog ishoda za motor - abrazivno trošenje njegovih dijelova. I čišćenje i ispiranje elementa krute velike čestice utjelovljenog u meku površinu ne može pomoći.

Drugim riječima, abrazivno trošenje je rezultat rezanja ili grebanja učinaka krutih čestica konjugiranih elemenata ili rezultata prašine iz dijelova prašine dovedenih s mazivom ili zrakom. Abrazivno trošenje motora obično se manifestira u obliku precijenjene potrošnje ulja.

Studija oštećenih elemenata otkriva drugačiju prirodu štete:

- Obrazovanje na klipnoj suknji širokog mat mat u kontakt s maksimalnog bočnog opterećenja, kao i s suprotne strane.

- Pojava profila obrade nose klipnu suknju.

- Obrazovanje na klipnim prstenovima, rukav ili cilindrični zid, kao i klipska suknja, tanke brazde tijekom pokreta.

- Pojava trošenja visine na klipnim prstenovima i njihovim žljebovima.

- Povećajte toplinsku prazninu na klipnim prstenovima. Rubovi prstena izrađeni su iznimno oštrim.

- Nošenje radnih rubova niskotlačnog prstena.

- Na klipnom prstu su brazde valovitog profila.

- Na drugim elementima uočeni su tragovi abrazivnog trošenja, na primjer, na terminalu ventila.

Način rada, utjecaj na trajnost motora

Na proširenju motornog resursa i kvalitete njegovog rada također utječe na način rada u kojem se vozilo radi. Proizvođači ne mogu osigurati svoje jedinice snage iz svih abnormalnih načina rada, u kojima se pokreće motor. Rastrg vožnje način, oštri počinje s scene ne pomaže povećati resurs motora i, naprotiv, smanjuje se. Da biste proširili resurs jedinice za napajanje, potrebno je odabrati jedinstvenu autocestu za vožnju bez naglih zaustavljanja i počinje.

Započnite i zagrijavanje motora, kako utječu na život motora

Rad napajanja na visokim frekvencijama rotacije radilice i maksimalnih opterećenja može značajno smanjiti svoj resurs (za 30 posto ili više). Važno je napomenuti da prekoračenje dopuštenog broja revolucija dovodi do uništenja elemenata motora.

Oko 70 posto trošenja motora pada na način rada za pokretanje. Posebno je pomaže u smanjenju hladnoće resursa, ako je mazivo s neprikladnim karakteristikama viskoznosti pokrivena u jedinici napajanja. Prije svega, povezan je s visokom viskoznošću materijala za podmazivanje na niskoj temperaturi - tako da je ušlo u parove trenja je potrebno više vremena.

Kratki izleti zimi na motoru doprinose pojavu depozita u sustavu maziva i korozijskog trošenja cilindara, klipova i njihovih prstena.

Duge sranja, dobro ili loše

Značajno smanjiti resurs motora kršenja uvjeta podmazivanja ležaja, kao i cijeli cylindropore sustav. Negativan utjecaj ima negativan utjecaj kratkih putovanja s dugim zaustavljanjem. U isto vrijeme, svojstva lubrikanta pogoršavaju se pogoršavaju, a depoziti nastaju na zidovima kanala. Zapamtite da prije stavljanja vozila na "zimovanje", potrebno je održati nekoliko događaja, što će zaštititi motorne cilindre i samu jedinicu za napajanje od korozije. Treba napomenuti da duga neaktivnost motora i automobila u cjelini dovodi do pojave kvarova i defekata, što značajno smanjuje motor "života".

Jahanje oko grada također značajno smanjuje resurs jedinice za napajanje, jer vozač mora biti vrlo često usporiti. Resurs automobilskih motora koji se kreću na značajne udaljenosti mnogo je veći, jer motor nije izložen visokim opterećenjima.

Održavanje i pravovremeno popravak

Potrebno je osigurati pravovremeno održavanje i dijagnostiku motora. Na vrijeme mijenjati za hlađenje tekućine, maziva i podešavanje željene čvorova i jedinica. Smanjenje interval filtra i zamjena ulja u zimskom značajno povećava motora resurs. Međutim, samo kvalitetni filteri i ulja treba koristiti.

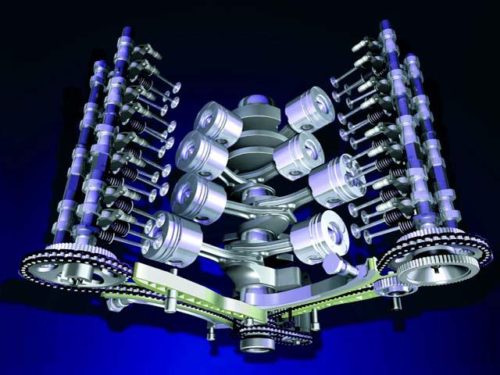

Dizajn rješenja kako oni utječu na trajnost motora

Motorna konstruktivna rješenja su u mogućnosti da postanu odlučujući faktor koji utječe na vijek trajanja agregata. U stvari, svaki model ovog mehanizma ima svoje definirane značajke dizajna. Kad za jedno vozilo, mali poremećaji u sustavu prehrane, maziva i paljenja nisu bitne, onda za drugi motor, oni mogu postati destruktivni. Usklađenost s preporukama proizvođača i pravilan rad automobila je ključ za trajnost i pouzdanost motora.

Savjeti Pros: Idemo zbrojiti gore

Od svega navedenog, može se zaključiti da je produženje resursa za agregat ima utjecaj na masu faktora koji ni postojati na početku ili se javljaju tijekom rada. Nema sitnica u ovom pitanju. U većini slučajeva, povećanje resursa ovisi o povećanom pažnjom na stanje važnih mehanizama i o uvjetima rada agregata.

Povezani materijali

- Peć 2110, loš topli štednjak 2110, VZ 2110 Sustav grijanja, popravak sustava grijanja VAZ 2110 vlastitim rukama

- VAZ 2114 štednjak puše s hladnim zrakom, štednjak 2114, loš topli štednjak vaz 2114, uređaj i popravak grijanja VAZ 2114 do-it-yourself, uklanjanje štednjak VAZ 2114

- Kako subdominatizirati automobil. Kako staviti utičnicu. Vrste priključnica za automobile.

- VAZ 2109 Blok osigurača, VZ 2109 Blok osigurača, VZ 2109 Blok osigurača Blok, stari VAZ 2109 Blok osigurača, VAZ 2109 osigurač blok, vaz osigurač blok 2109

- Katalizator ispušnih plinova automobila, neispravan katalizator, pluse i mane katalizatora, kako promijeniti katalizator na ramencitel

- Štednjak puhanje hladnog zraka vaz 2114, loše puhanje štednjak vaz 2114, zašto loše puše štednjak vaz 2114

- Kako saznati vlasnik automobila po broju automobila, provjeriti automobil po broju prometnog policijskog stroja, provjeriti automobil od strane državnog broja automobila besplatno

- Kako odabrati rabljene gume, korisne savjete

- Zimski automobil, tlak u putničkim automobilima zimi, dobru bateriju za automobil zimi, hoće li zimi zagrijati automobil

- Zimi je automobil slabo pokrenut. Kako napraviti auto zimi, trebate li zagrijati automobil zimi, korisne savjete

- Strojevi za potrošnju goriva u gospodarstvu, najekonomičniju potrošnju automobila

- Gume brandova za osobna vozila, označavanje označavanja guma automobila, zaostalo putničkog automobila zaštitnika guma, kako odabrati gumu na marku automobila, uzorak gaznoga sloja automobila

- Rad prijenosa Rad, mehanički mjenjač kvačilo, vožnja s ručnim mjenjačem, korisnim savjetima

- Stražnji snop peugeot 206 limuzi, stražnji snop peugeot 206. Stražnji snop Peugeot 206 kvarovi, popravak stražnjeg snopa Peugeot 206

- Dizel gorivo zimi, aditiv za dizelsko gorivo zimi, kako odabrati najbolje dizelsko gorivo

- Dizel zima ne počinje. Kako započeti dizel zimi, grijanje dizel zimi.

- Japanci Bridgestone gume, zimska okovana Bridgestone gume, brand Bridgestone gume

- Označavanje guma Dekodiranje za osobne automobile, označavanje kotača, kako odabrati desne gume na diskovima

- Dizelski motor zimi, pokretanje dizelskog motora zimi, što ulje popunjava dizelski motor zimi, korisni savjeti

- LED pozadinsko osvjetljenje automobila, pozadinsko osvjetljenje dna automobila, pozadinsko osvjetljenje nogu u automobilu, pozadinsko osvjetljenje na vratima automobila, pozadinsko osvjetljenje automobila je u redu

- Oporavljene gume, guma autobusa, obnovljena zaštitnica guma, mogu li ih koristiti

- Odaberite zimske gume, koje su zimske gume, koje tlak u zimskim gumama trebaju biti označene zimskim gumama, kako odabrati prave zimske gume, najbolje zimske gume 2019

- Upravljač željeznicom, kucanje upravljačkog stalka, razlozi za kucanje i popravak raka upravljača to čine sami

- Gume za automobile bez grešaka, skup za popravak guma bezbojnih, popravak gume bez topova

- Ruske gume, ruske gume zime, ruske cijele sezonske gume, Voronezh Amtel gume, gume "Matador Omsk guma", Kama-gume su svjetski razred autobus

- Kako otvoriti automobil bez ključa. Izgubio je ključ od automobila što učiniti, ključ od automobila unutar automobila

- Tihe gume, mirne zimske gume, miran sabirni autobus, koje gume biraju, pregledavaju gume

- Gume i sigurnost, sigurnost autobusa, zašto je potrebno stalno pratiti auto gume

- Pravila sigurnog vožnje automobila u kiši i bljuzganju, sigurna vožnja automobila za početnike

- Converter za hrđu koji je bolji za automobile, RUST pretvarači da biraju kako koristiti transducer za hrđu, profesionalce

- Poliranje tijela automobila to učiniti sami, kako odabrati poliranje paste, korisne savjete

- Kucati u auto. Knock prilikom premještanja automobila. Što može kucati u autu. Kako odrediti uzrok kucanja.

- ABS Car, što je ABS CAR, ABS sustav kvar, ABS dijagnostika

- Pretjecanje automobila kada možete početi pretjerivati \u200b\u200bautomobil, pravila prometnih pravila

- Pumpa za gorivo VAZ 2110, VZ 2110 Shema benzinske postaje, VZ 2110 uređaja za pumpe za gorivo, VAZ 2110 Popravak benzinske postaje,

- Automobilske antene za radio, automobilsku antenu, auto antene to učiniti sami

- Prednji suspenzija Kalina, prednja suspenzija uređaja Kalina, kucanje u prednjoj suspenziji Kalina, popravak prednjeg ovjesa Kalina

- Ulje za apsorpciju udara, najbolje apsorberi ulja za ulje, pumpanje ulja amortizeri, kako pravilno pumpati uljni amortizer

- Kvačilo kvačilo, dodiruje kvačilo, uzrokuje kvačilo kvačilo, kako eliminirati

- Vislice ventilatora, radne uniforme ventilatora, kvar ventilatora ventilatora, popravak ventilatora ventilatora

Komentari