Automobilska mlaznica je uređaj koji je odgovoran za direktno raspršivanje goriva unutar komore za izgaranje. Do danas, postoji nekoliko izmjene ovog uređaja. O tome dalje u članku.

Sadržaj

- Sustav ubrizgavanja goriva, od kojih je sustav ubrizgavanja sastoji od

- Izravno ubrizgavanje ili za ono što vam je potrebno mlaznice u motoru

- vrste mlaznica i njihova svrha

- Elektromagnetski mlaznica, uređaj i princip rada

- Benzin mlaznica u kontekstu

- Dizel mlaznice, Diesel motor mlaznice, uređaja i princip rada

- Piezoforun, uređaj

- Piezohoroforsunk, princip rada

- Piezohoroforsunk, dostojanstvo

Sustav ubrizgavanja goriva, od kojih je sustav ubrizgavanja sastoji od

Sustav goriva sastoji se od takvih elemenata:

- Top žarulje.

- Spremnik za gorivo.

- Pumpa za gorivo.

- Filtri za gorivo.

- Uređaj za miješanje zraka i goriva.

- Gorivo kontrolu tlaka.

- Usisni razvodnik.

- Zračni filter.

- Senzori.

- Prigušivač buke ispušnih plinova.

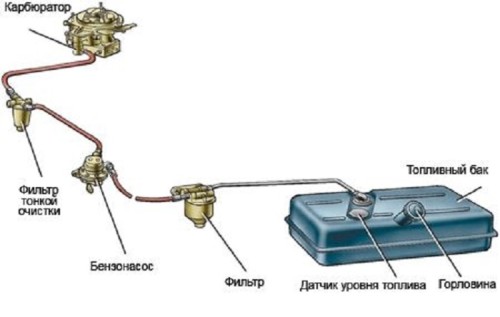

Ovisno o uređaju koji se koristi za miješanje zraka i goriva, postoje tri vrste sustava za gorivo:

- Punjiva Sustav goriva - koristiti u dizelskim motorima.

- Karburator Sustav goriva - koristi se u karburator motore.

- Brizgaljki Sustav goriva - koristi se u benzinskim motorima. U tom slučaju, za miješanje zraka i goriva je odgovorna za mlaznice.

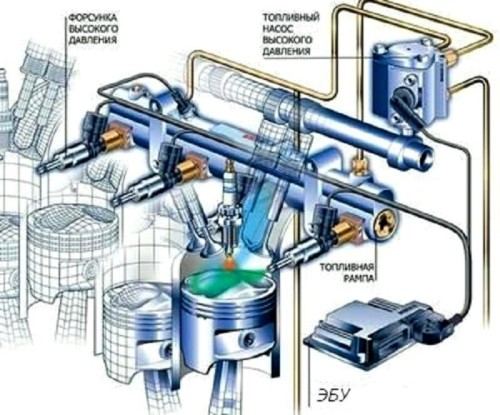

Izravno ubrizgavanje ili za ono što vam je potrebno mlaznice u motoru

Izravno injekcija je modifulacija distribuirane injekcije goriva, gdje se gorivo ubrizgava u cilindre izravno. Mlaznica je glavna obvezujuća komponenta između pumpe za gorivo i motora. Glavna svrha mlaznica:

- Osiguravanje ispravne doze goriva koji se isporučuje na motor.

- Osiguranje ispravnog mlaza (količine, tlak, kut) smjese.

Vrste mlaznica i njihova svrha

Elektromagnetska mlaznica, uređaj i princip rada

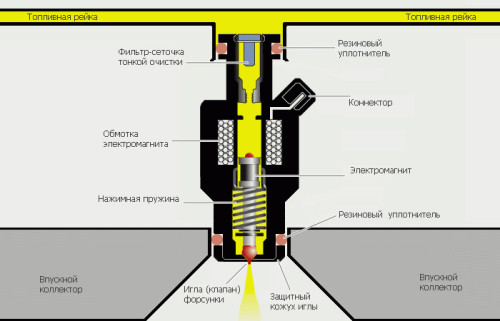

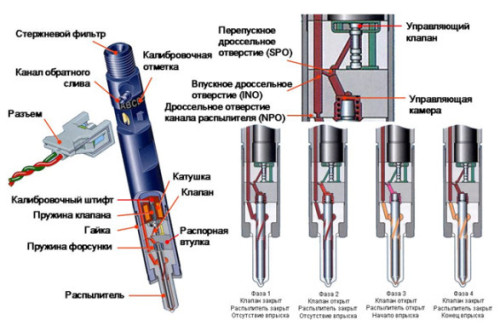

Takvi elektromagnetski uređaji koriste se, u pravilu, na benzinskim motorima, uključujući i izravno ubrizgavanje. Ova vrsta opreme ima prilično jednostavan dizajn koji se sastoji od:

- Mlaznica mlaznice.

- Igla.

- Pečat na kućištu.

- Kućište mlaznice.

- Sidro od elektromagnet.

- Posebno proljeće.

- Elektromagnetsko namotavanje uzbude.

- Električni priključak.

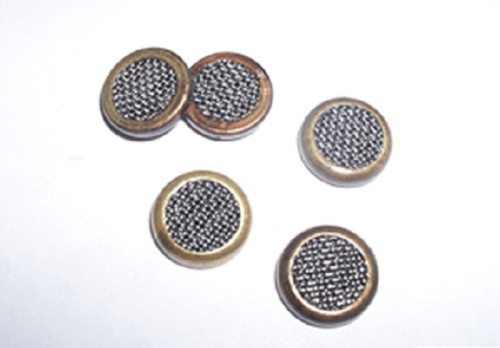

- Mesh filtar.

Mlaznica obavlja prskanje goriva. To je iz kvalitete rada ove komponente ovisi o radu cijelog uređaja. Mesh filter filtrira gorivo koje prolazi kroz mlaznicu.

ECU, koji odgovara prethodno postavljenom algoritmu, u traženom trenutku osigurava opskrbu napona namotanju ekscitacije ventila. U procesu tog, nadilazi elektromagnetsko polje, prevladavanje proljetne sile, nakon čega se odgađa sidro s iglom, koja oslobađa mlaznicu. Uostalom, to je injekcija goriva. Kada napon nestane, igla mlaznice se vraća na sedlo pomoću proljeća.

Benzina mlaznica u kontekstu

- Mesh filtar.

- Mlaznica mlaznice.

- Pečat.

- Mlaznica igle.

- Kućište mlaznice.

- Sidro elektromagnet.

- Namotavanje u kabini.

- Proljeće.

- Električni priključak.

Dizel mlaznica, mlaznice dizel motora, uređaj i princip rada

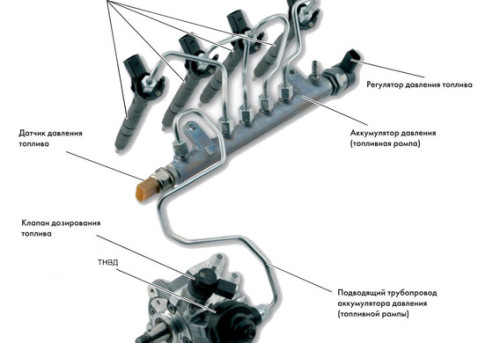

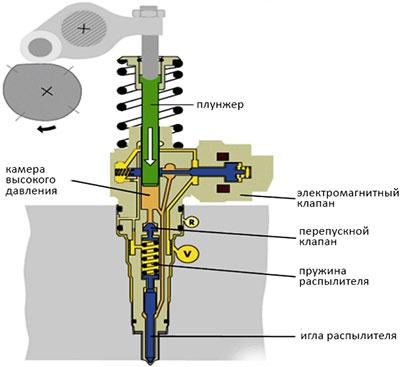

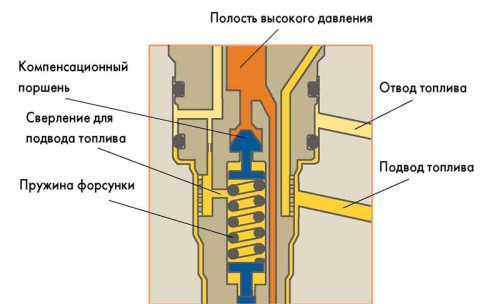

U dizelskim motorima, uključujući i one opremljene s "zajedničkim željezničkim" sustavom za ubrizgavanje, koriste se elektrohidraulične mlaznice. Dizajn ovog uređaja uključuje elektromagnetski ventil, kontrolnu komoru, kao i odvod i usisnu gušenje.

Načelo djelovanja takve opreme temelji se na korištenju tlaka goriva tijekom injekcije, kao i nakon završetka. U početnom položaju, solenoidni ventil je potpuno zatvoren i de-energiziran, igla uređaja se pritisne na sedlo s tlakom na klip za gorivo u upravljačkoj komori. Ubrizgavanje goriva u ovom položaju se ne izvodi. Važno je napomenuti da je pritisak goriva na iglu, u ovoj situaciji, manje tlaka, koji se proizvodi na klip, kao rezultat razlike u kontaktnim područjima.

Nakon zapovjedništva ECU-a se aktivira solenoidni ventil i otvori se odvodno gas. Gorivo, koje se nalazi u kontrolnoj komori, dok teče kroz gas u autocestu odvoda. Unos prigušnica je prepreka najbržem niveliranju pritisaka u ulaznoj liniji i kontrolnoj komori. Postupno postoji smanjenje tlaka na klip, međutim, tlak goriva koji se vrši na iglu ne mijenja, što rezultira podizanjem injekcije i injekcije goriva.

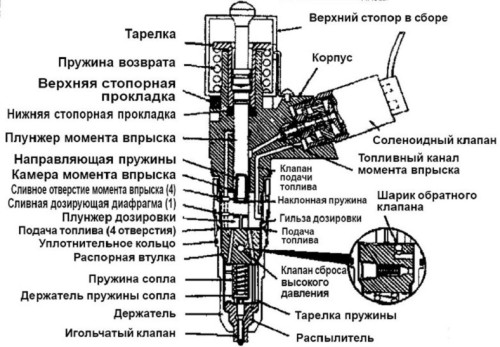

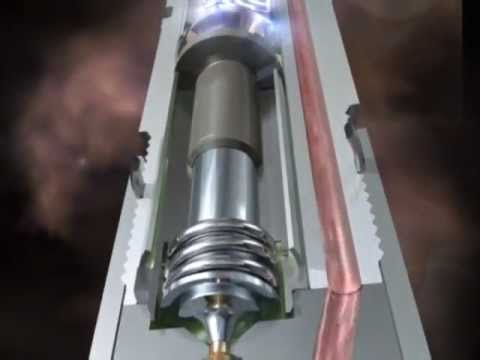

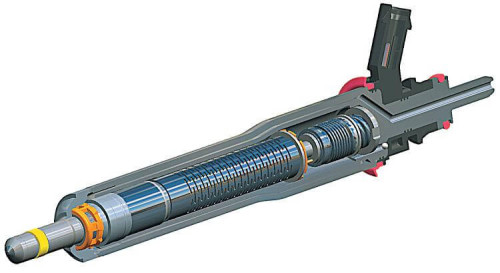

Piezoforun, uređaj

Dizajn piezokomija uključuje takve komponente:

- Kanal za opskrbu gorivom.

- Konektor za električnu mlaznicu.

- Mikrofilter.

- Uzgoj kanala.

- Piezolament.

- Klipni potiskivač.

- Klip ventila.

- Proljetni ventil.

- Prebacivanje ventila.

- Blok.

- Prskalica proljetne igle.

- Vatrootporna perilica.

- Igla prskalice.

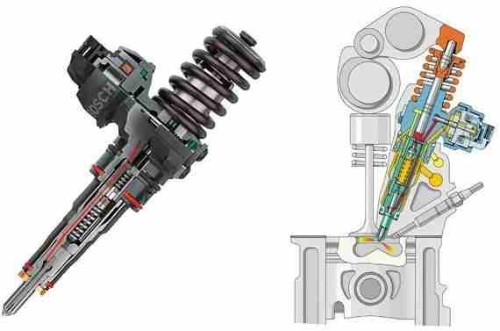

Piezohohoroforsunk, načelo rada

Rad upravljačkog ventila mlaznice temelji se na dobro poznatom piezoelektričnom učinak, na primjer, u plinskim upaljačima. Čovjekov prst pritisne gumb koji deformira radnu komponentu iz dielektrika. Kao rezultat toga, naplata se koristi za upamljivanje plina.

U piezoelektričnim mlaznicama, t. N. Obrnuti piezoelektrični učinak. Napon se dovodi do dielektrika, što doprinosi deformaciji materijala. Šipka ventila je povezana s njom, koja se može penjati ako se struja dovodi do mlaznice.

Piezohohoroforsunk, dostojanstvo

- Visoke učinkovitosti mlaznice.

- Smanjenje buke u procesu motornog rada.

- Sposobnost promjene tlaka ubrizgavanja.

- Povećajte brzinu mlaznice.

Povezani materijali

- Peć 2110, loš topli štednjak 2110, VZ 2110 Sustav grijanja, popravak sustava grijanja VAZ 2110 vlastitim rukama

- VAZ 2114 štednjak puše s hladnim zrakom, štednjak 2114, loš topli štednjak vaz 2114, uređaj i popravak grijanja VAZ 2114 do-it-yourself, uklanjanje štednjak VAZ 2114

- Kako subdominatizirati automobil. Kako staviti utičnicu. Vrste priključnica za automobile.

- VAZ 2109 Blok osigurača, VZ 2109 Blok osigurača, VZ 2109 Blok osigurača Blok, stari VAZ 2109 Blok osigurača, VAZ 2109 osigurač blok, vaz osigurač blok 2109

- Katalizator ispušnih plinova automobila, neispravan katalizator, pluses i kontra katalizatora, kako promijeniti katalizator za CAMENancitel

- Štednjak puhanje hladnog zraka vaz 2114, loše puhanje štednjak vaz 2114, zašto loše puše štednjak vaz 2114

- Kako saznati vlasnik automobila po broju automobila, provjeriti automobil po broju prometnog policijskog stroja, provjeriti automobil od strane državnog broja automobila besplatno

- Kako odabrati rabljene gume, korisne savjete

- Zimski automobil, tlak u putničkim automobilima zimi, dobru bateriju za automobil zimi, hoće li zimi zagrijati automobil

- Zimi je automobil slabo pokrenut. Kako napraviti auto zimi, trebate li zagrijati automobil zimi, korisne savjete

- Strojevi za potrošnju goriva u gospodarstvu, najekonomičniju potrošnju automobila

- Gume brandova za osobna vozila, označavanje označavanja guma automobila, zaostalo putničkog automobila zaštitnika guma, kako odabrati gumu na marku automobila, uzorak gaznoga sloja automobila

- Rad prijenosa Rad, mehanički mjenjač kvačilo, vožnja s ručnim mjenjačem, korisnim savjetima

- Stražnji snop peugeot 206 limuzi, stražnji snop peugeot 206. Stražnji snop Peugeot 206 kvarovi, popravak stražnjeg snopa Peugeot 206

- Dizel gorivo zimi, aditiv za dizelsko gorivo zimi, kako odabrati najbolje dizelsko gorivo

- Dizel zima ne počinje. Kako započeti dizel zimi, grijanje dizel zimi.

- Japanci Bridgestone gume, zimska okovana Bridgestone gume, brand Bridgestone gume

- Označavanje guma Dekodiranje za osobne automobile, označavanje kotača, kako odabrati desne gume na diskovima

- Dizelski motor zimi, pokretanje dizelskog motora zimi, što ulje popunjava dizelski motor zimi, korisni savjeti

- LED pozadinsko osvjetljenje automobila, pozadinsko osvjetljenje dna automobila, pozadinsko osvjetljenje nogu u automobilu, pozadinsko osvjetljenje na vratima automobila, pozadinsko osvjetljenje automobila je u redu

- Oporavljene gume, guma autobusa, obnovljena zaštitnica guma, mogu li ih koristiti

- Odaberite zimske gume, koje su zimske gume, koje tlak u zimskim gumama trebaju biti označene zimskim gumama, kako odabrati prave zimske gume, najbolje zimske gume 2019

- Upravljač željeznicom, kucanje upravljačkog stalka, razlozi za kucanje i popravak raka upravljača to čine sami

- Gume za automobile bez grešaka, skup za popravak guma bezbojnih, popravak gume bez topova

- Ruske gume, ruske gume zime, ruske cijele sezonske gume, Voronezh Amtel gume, gume "Matador Omsk guma", Kama-gume su svjetski razred autobus

- Kako otvoriti automobil bez ključa. Izgubio je ključ od automobila što učiniti, ključ od automobila unutar automobila

- Tihe gume, mirne zimske gume, miran sabirni autobus, koje gume biraju, pregledavaju gume

- Gume i sigurnost, sigurnost autobusa, zašto je potrebno stalno pratiti auto gume

- Pravila sigurnog vožnje automobila u kiši i bljuzganju, sigurna vožnja automobila za početnike

- Converter za hrđu koji je bolji za automobile, RUST pretvarači da biraju kako koristiti transducer za hrđu, profesionalce

- Poliranje tijela automobila to učiniti sami, kako odabrati poliranje paste, korisne savjete

- Trajnost motora, život motora, kako produžiti život motora

- Kucati u auto. Knock prilikom premještanja automobila. Što može kucati u autu. Kako odrediti uzrok kucanja.

- ABS Car, što je ABS CAR, ABS sustav kvar, ABS dijagnostika

- Pretjecanje automobila kada možete početi pretjerivati \u200b\u200bautomobil, pravila prometnih pravila

- Pumpa za gorivo VAZ 2110, VZ 2110 Shema benzinske postaje, VZ 2110 uređaja za pumpe za gorivo, VAZ 2110 Popravak benzinske postaje,

- Automobilske antene za radio, automobilsku antenu, auto antene to učiniti sami

- Prednji suspenzija Kalina, prednja suspenzija uređaja Kalina, kucanje u prednjoj suspenziji Kalina, popravak prednjeg ovjesa Kalina

- Ulje za apsorpciju udara, najbolje apsorberi ulja za ulje, pumpanje ulja amortizeri, kako pravilno pumpati uljni amortizer

- Kvačilo kvačilo, dodiruje kvačilo, uzrokuje kvačilo kvačilo, kako eliminirati

Komentari