Kočni sustav u automobilskim prijevozu je najvažnije tijelo, što rezultira bilo kakvim, čak i minimalne manifestacije njegovog netočnog rada, kao što je zviždaljka, škripanje, škripanje i drugi, trebaju se dijagnosticirati na vrijeme i eliminirati. Ono što ti zvuči označavaju i kako eliminirati škripanje kočnice - pročitati dalje u članku.

Sadržaj

- Novi kočioni jastučići, razlozi za screenshotove

- Poricanje kočionih jastučića nakon nekog iskorištavanja, zašto su stisnuli

- Škripanje kočionih jastučića zbog vibracija, razloga vibracija, kako eliminirati

- Podmazivanje za kočnice, kakav je potreban mazivač i kako ga koristiti

- Vibracije i škripanje kočionih jastučića zbog loša kvaliteta montaže, obratite pažnju prilikom pričvršćivanja kotača u kojima je opasnost

- Diskovi kočnica su topli, posljedice rada automobila s neispravnim kočionim sustavom

- Kako provjeriti diskove pri kupnji, obratiti pozornost, minimalnu toleranciju za devijaciju debljine diska na površini

- Savjeti pros: kako spasiti život vozaču i auto

Novi kočioni jastučići, razlozi za screenshotove

Preskakanje jastučići rezultat su njegovih oscilacija u procesu trenja na kočionom disku, koji je glavni rezonator. Mnogi različiti čimbenici utječu na taj proces. Da bi se uklonili buka, proizvođači cijevi koriste posebne anti-ocjenjive ploče, ali su montirane samo na "transportne cipele" - u svrhu uštede na prodaju na sekundarnom tržištu koji nisu instalirani.

Najčešći uzrok snimke zaslona je loša kvalitetna materijalna jastučići. Svaki jastučić trenje je polimerni sastav mase elemenata. Jeftini proizvođači proizvoda spremiti i koristiti jeftin sastav za stvaranje jastučića. Međutim, nisu svi škripavi jastučići loši. Drugi mogući uzrok njihove violine je nekompatibilnost s kočionim diskovima. Stoga je potrebno kupiti kočione pločice i diskove jednog proizvođača.

Ako su novi, samo instalirani kočni jastučići, najvjerojatnije, trebaju neko vrijeme za rad. Pričekajte malo, možda će proći neugodan buka. A to se događa jer je vrh na bloku poseban sloj s dodatkom koji uzrokuje suprotan zvuk. Tijekom vremena mora nestati (s punom abrazijom ovog sloja). Da biste brzo dobili osloboditi od screenshot, napravite intenzivno kočenje.

Ako nakon određenog pokretanja jastučića nastavite zviždati i škripati, morate ih zamijeniti. Također, škripanje u kočnicama pojavljuje se kao rezultat njihovog onečišćenja ili uđenja vode. U ovom slučaju, potrebno je ili očistiti jastučiće ili čekati neko vrijeme.

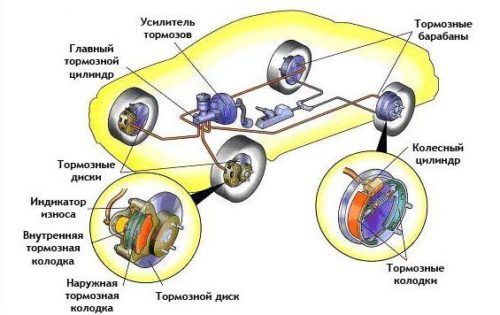

Poricanje kočionih jastučića nakon nekog iskorištavanja, zašto su stisnuli

Svaki kočni jastučići su opremljeni posebnim indikatorom trošenja (t. N. "Piskuna"), koji izgleda kao metalna ploča. Uz jako trošenje jastučića, ova ploča je u kontaktu s kočionim diskom, zbog čega se pojavljuje škripanje ili škripanje. To signalizira hitnu zamjenu kočionih jastučića.

Ovaj škripac se također može manifestirati na novim jastučićima, što se događa kao rezultat loše kvalitete pričvršćivanja ploče, zbog čega je prerano u kontaktu s diskom i čini neugodan zvuk.

Osim toga, kočnice mogu škripati iz vrućine. Ovaj škripanje nije jak, ali ipak je prisutan. S intenzivnim pokretom oko grada, naizmjenično overclocking i kočenje, čak i izvorni jastučići mogu malo škripati. To se događa u automobilima, na kojima nisu montirani ventilirani kočioni diskovi. Prema tome, jastučići su rijetko i objavljuju škripanje, ali je beznačajno i brzo eliminira kada se jastučić ohladi.

U procesu zamjene jastučića, preporučuje se podmazivanje vola za vođenje pomoću posebnog maziva, jer je još jedan uzrok kočnog zaslona.

Pojava vioup nesumnjivo uzrokuje neugodne osjećaje, ali ne utječe na učinkovitost kočenja. Ako ste uvjereni da je škripanje uzrokovan ne-kočionim jastučićima, pregledajte i očistite kočioni sustav pomoću posebnih sredstava. Moguće je da će montaža-demontaže, kao i mazivo svih pokretnih elemenata pomoći da se riješite zaslona.

Škripanje kočionih jastučića zbog vibracija, razloga vibracija, kako eliminirati

Auto-oscilacija nastavlja ne od kočionog čeliča ili diska, već iz kočionih jastučića. Iako se vibracija formira sve elemente kočnog sustava, diskovi i čeljust su vrlo tvrdi, što je rezultiralo apsorpcijom vibracija, međutim, jastučić, a zatim ostaje u pokretu niskog amplituda, tako da vozač i čuje ovaj kočenje škripanje i škripati. U tom slučaju, ne biste trebali kriviti sve jastučiće u svemu, potrebno je distribuirati cijeli sustav i otkriti uzrok podataka o oscilacijama. Zapravo, postoji nekoliko takvih razloga:

- Niske kvalitete kočionih jastučića. To je, za preklapanje, obloge je zauzela loš ljepljivu smjesu, obloge su nehomogene u sastavu i tako dalje.

- Klip se ne u potpunosti ispravno kreće u rudniku čeljusti, kao posljedica toga što se nejasnoće pojavljuje u kočnicama.

- Vodiči "suho" čeljust, zbog čega su kočnice blago iskrivljene.

- Diskovi kočnica se jednostavno istroše, kao rezultat kojih je "bin" formiran duž promjera vanjskog diska.

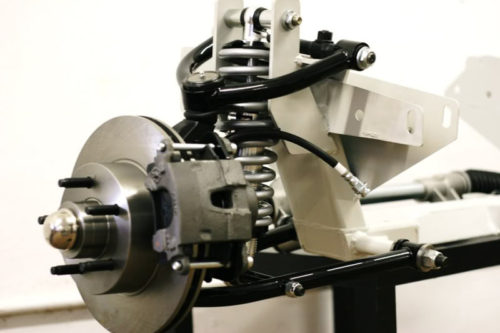

Riješite probleme zbog kojih vibriraju kočnice vibracije:

- Izvadimo pražnjenje na disk koristeći njegov utorovi, ali samo kada debljina sloja za popravak omogućuje obavljanje takvog rada. Ili ćete morati zamijeniti kočione diskove, jer kada instalirate čak i najmodenije i strme kočne pločice, usjev i škripanje neće proći u svakom slučaju.

- Prije instaliranja novih jastučića, provjerite čeljust za prisutnost problema, posebno, provjerite rad vodilica i klipova. Vodiči obvezno podmažite posebnim materijalom koji smanjuje trenje.

- Osim toga, prije ugradnje novih kočionih jastučića, trebali bi razmazati njihove ciljeve, kao i stražnji zid obloge uz pomoć posebne anti-stupnjeve paste. Naravno, zabranjeno je dodirnuti radnu površinu cipele.

Podmazivanje za kočnice, kakav je potreban mazivač i kako ga koristiti

Postoje dvije vrste maziva kočnica - keramike i otporne na toplinu.

Keramička maziva za čeljusti se odlikuju mikroskopskim keramičkim česticama u njihovom sastavu, s kojim se osiguravaju visoka učinkovitost kočnice u različitim uvjetima. Ako ispravno pokupite tekućinu za kočnice, moguće je izbjegavati ne samo zistiranje i ometanje komponenti čeljusti, nego i potpuno eliminirati bilo kakav drobljenje ili škripanje. Elementi će biti najsigurniji zaštićeni od opasnog učinka prljavštine, prašine i vlage, kao i sve vrste kapi temperature.

Osim toga, keramičke paste se odlikuju visokom otpornošću na koroziju i nisu gužve od naslaga u cijelom radnom životu. Savršeno se kombinira s bilo kojim podložnim materijalima. Pasta se ne primjenjuje na površinu jastučića ili diska. Koristi se za podmazivanje elemenata za kaliper za kočnica diska. Dobar izbor - keramička maziva iz Liqui Moly, Permatex, Presto, Bardahl.

Korištenje pasta otpornih na toplinu - plutajuće ploče, površinski jastučići i nosači. Odličan izbor za većinu modela je visokotemperaturna pasta za kočnice Liqui Moly i Molykote Cu-7439 Plus. Ove prošle vrste dokazali su se s prilično visokim tlakom i temperaturama, kao i na mjestima gdje se očekuje hrđa.

Prilikom odabira paste kočnice, treba napomenuti da mora nužno ispunjavati sljedeće zahtjeve:

- Otpornost na različite kemijske učinke.

- Otpornost na vodu.

- Dobar toplinski otpor.

- Kompatibilnost s plastikom.

- U uvjetima visokih temperatura ne bi se trebala manifestirati. "Učinak kapple".

Vibracije i škripanje kočionih jastučića zbog loša kvaliteta montaže, obratite pažnju prilikom pričvršćivanja kotača u kojima je opasnost

Zbog jakne materijala trenja ili netočne montaže, defekti se mogu pojaviti na radnoj površini diska, koji, zauzvrat, podrazumijeva škripanje i vibracije. Da biste riješili problem, trebali potopiti površinu diska ili provoditi mjere kako biste osigurali ravnost kočionog diska, za koju rastavljamo disk, pažljivo očistite površinu čvorišta iz kontaminacije i hrđe, a zatim ponovno instalirajte disk kočnice. Na perifernom dijelu diska provjeravamo beyon s mikrometrom, koji je fiksiran na magnetskoj bazi. Ako vrijednost premlaćivanja premašuje 0,1 mm, pokušajte ponovno instalirati disk kočnice, okreće ga na 180 ili 90 stupnjeva u odnosu na hub ako vam omogućuje da napravite konfiguraciju rupa. Ako problem ostane, promijenite disk kočnice.

Ne rijetki vlasnici automobila ne griješe s neovisnim instalacijskim jastučićima, koji su namijenjeni za određenu stranu, a također i nepravilno postavljaju anti-pomaknuti uređaji (obloge), što može dovesti do ne samo škripanje, ali i drugih, ozbiljnijih problema. Stoga, kada instaliranje kočionih jastučića na to treba obratiti posebnu pozornost.

Diskovi kočnica su topli, posljedice rada automobila s neispravnim kočionim sustavom

Naravno, glavni razlog zbog kojeg kočioni diskovi koče - kočenje, koji se provodi interakcijom kočionog diska s blokom. U ovom trenutku je disk zagrijan. Važno je napomenuti da se to dogodi odmah, ali nema vremena za hlađenje kočionog diska, osobito ako govorimo o vožnji u urbanom načinu rada.

Drugi, ne manje važan uzrok grijanja diskova - stil vožnje. Svaki vozač je individualan i, vjerojatno, nije potrebno objasniti da s agresivnim načinom vožnje u urbanim uvjetima, to jest, ekstremno kočenje i oštro ubrzanje, diskovi kočnica će se kontinuirano zagrijavati.

I konačno, postoji kvar sustava kočnice. Točnije njegovi pojedini dijelovi ili čvorovi. Razmotrite ih detaljnije:

- Ne-kvalitetne kočione pločice (obloge).

- Debljina kočionih jastuka i debljina kočnog diska je manja od minimalno-dimenzionalnog proizvođača.

- Diskovi kočnice.

- Korištenje mješovitog sustava kočionog mehanizma. Stražnje kočnice - bubanj, prednje kočnice - disk. To je težak uzrok zagrijavanja prednjih kočionih diskova, jer glavno opterećenje tijekom kočenja pada na prednju osovinu.

Trajni intenzivni jastučići za grijanje i diskovi mogu podrazumijevati promjenu svojstava materijala iz kojih su napravljeni. Istodobno se formira maligni film između kočionih diskova i jastučića, koji ima sposobnost da značajno smanji koeficijent trenja kočionih jastučića oko površine diska. Kao rezultat toga, učinkovitost cijelog kočnog sustava značajno se smanjuje. Čak i ako se vozač nekako prilagođava oslabljenju kočenja, riješi problem s vrelicom tekućine kočnice u svakom slučaju, to neće biti moguće.

To može podrazumijevati kvar cijelog kočnog sustava. U većini slučajeva, snažno pregrijavanje dovodi do kvara kočionika i jastučića. Ako su kočioni diskovi topli nakon zamjene jastučića, moguće je da je korozija u blizini gume cilindra kočnice izvor subfline.

Kako provjeriti diskove pri kupnji, obratiti pozornost, minimalnu toleranciju za devijaciju debljine diska na površini

Prilikom kupnje rabljenog kočnog diska, prije svega, treba provjeriti pomoću debljine na nekoliko mjesta. Zašto? Da, jer postoji fenomen kao nejednako trošenje diska, što se događa iz raznih razloga. Također nacrtajte vizualni pregled kočionog diska za duboke ogrebotine, boje i druge mehaničke oštećenja na radnoj površini diska.

Ako kupujete nove kočione diskove, obratite pozornost na njihov trošak. Kao što znate, kvalitetniji proizvod, to je skuplje. Bolje je dati prednost poznatim brandovima, budući da velike tvrtke brinu o svom ugledu i, u pravilu, nude klijentima samo visokokvalitetne proizvode.

Prijem na devijaciju debljine diska na cijeloj radnoj površini je 0,0035 milimetara. Ako ste pronašli nejediranje debljine diska kočnice izvan tolerancije, potrebno je zamijeniti ga, uključujući disk kočnice na osi. Ako se debljina diska promijeni unutar tolerancije, pokušajte ukloniti problem ponovnog stjecanja.

Međutim, ako ponavljanje ne dovodi do uspjeha, disk se može namočiti pomoću posebnog uređaja. No, u isto vrijeme, pobrinite se da je preostala debljina kočnog diska omogućuje to učiniti, a baterija glavnog dijela montiranog diska ne prelazi 0,05 milimetara. Sada se površina trenja mora izgladiti, osiguravajući potrebnu hrapavost - 3.2. Pa, preporučljivo je zamijeniti jastučiće. Ako se disk ne može natopiti, morat će se promijeniti.

Savjeti pros: kako spasiti život vozaču i auto

Prije svega, potrebno je dijagnosticirati, popraviti i promijeniti elemente kočionog sustava. Ne zaboravite da su kočnice jedan od najvažnijih čvorova automobila, pa čak i beznačajni problemi na prvi pogled su sposobni dovoditi do fatalnih posljedica. Zamotajte diskove iz umjetne deformacije. U vrućem vremenu zabranjeno je pranje vozila odmah nakon pokreta. Potrebno je da se kočioni diskovi ohladi, inače vaše vlastite radnje ćete ugroziti dio kočionog mehanizma.

Povezani materijali

- Peć 2110, loš topli štednjak 2110, VZ 2110 Sustav grijanja, popravak sustava grijanja VAZ 2110 vlastitim rukama

- VAZ 2114 štednjak puše s hladnim zrakom, štednjak 2114, loš topli štednjak vaz 2114, uređaj i popravak grijanja VAZ 2114 do-it-yourself, uklanjanje štednjak VAZ 2114

- Kako subdominatizirati automobil. Kako staviti utičnicu. Vrste priključnica za automobile.

- VAZ 2109 Blok osigurača, VZ 2109 Blok osigurača, VZ 2109 Blok osigurača Blok, stari VAZ 2109 Blok osigurača, VAZ 2109 osigurač blok, vaz osigurač blok 2109

- Katalizator ispušnih plinova automobila, neispravan katalizator, pluse i mane katalizatora, kako promijeniti katalizator na ramencitel

- Štednjak puhanje hladnog zraka vaz 2114, loše puhanje štednjak vaz 2114, zašto loše puše štednjak vaz 2114

- Kako saznati vlasnik automobila po broju automobila, provjeriti automobil po broju prometnog policijskog stroja, provjeriti automobil od strane državnog broja automobila besplatno

- Kako odabrati rabljene gume, korisne savjete

- Zimski automobil, tlak u putničkim automobilima zimi, dobru bateriju za automobil zimi, hoće li zimi zagrijati automobil

- Zimi je automobil slabo pokrenut. Kako napraviti auto zimi, trebate li zagrijati automobil zimi, korisne savjete

- Strojevi za potrošnju goriva u gospodarstvu, najekonomičniju potrošnju automobila

- Gume brandova za osobna vozila, označavanje označavanja guma automobila, zaostalo putničkog automobila zaštitnika guma, kako odabrati gumu na marku automobila, uzorak gaznoga sloja automobila

- Rad prijenosa Rad, mehanički mjenjač kvačilo, vožnja s ručnim mjenjačem, korisnim savjetima

- Stražnji snop peugeot 206 limuzi, stražnji snop peugeot 206. Stražnji snop Peugeot 206 kvarovi, popravak stražnjeg snopa Peugeot 206

- Dizel gorivo zimi, aditiv za dizelsko gorivo zimi, kako odabrati najbolje dizelsko gorivo

- Dizel zima ne počinje. Kako započeti dizel zimi, grijanje dizel zimi.

- Japanci Bridgestone gume, zimska okovana Bridgestone gume, brand Bridgestone gume

- Označavanje guma Dekodiranje za osobne automobile, označavanje kotača, kako odabrati desne gume na diskovima

- Dizelski motor zimi, pokretanje dizelskog motora zimi, što ulje popunjava dizelski motor zimi, korisni savjeti

- LED pozadinsko osvjetljenje automobila, pozadinsko osvjetljenje dna automobila, pozadinsko osvjetljenje nogu u automobilu, pozadinsko osvjetljenje na vratima automobila, pozadinsko osvjetljenje automobila je u redu

- Oporavljene gume, guma autobusa, obnovljena zaštitnica guma, mogu li ih koristiti

- Odaberite zimske gume, koje su zimske gume, koje tlak u zimskim gumama trebaju biti označene zimskim gumama, kako odabrati prave zimske gume, najbolje zimske gume 2019

- Upravljač željeznicom, kucanje upravljačkog stalka, razlozi za kucanje i popravak raka upravljača to čine sami

- Gume za automobile bez grešaka, skup za popravak guma bezbojnih, popravak gume bez topova

- Ruske gume, ruske gume zime, ruske cijele sezonske gume, Voronezh Amtel gume, gume "Matador Omsk guma", Kama-gume su svjetski razred autobus

- Kako otvoriti automobil bez ključa. Izgubio je ključ od automobila što učiniti, ključ od automobila unutar automobila

- Tihe gume, mirne zimske gume, miran sabirni autobus, koje gume biraju, pregledavaju gume

- Gume i sigurnost, sigurnost autobusa, zašto je potrebno stalno pratiti auto gume

- Pravila sigurnog vožnje automobila u kiši i bljuzganju, sigurna vožnja automobila za početnike

- Converter za hrđu koji je bolji za automobile, RUST pretvarači da biraju kako koristiti transducer za hrđu, profesionalce

- Poliranje tijela automobila to učiniti sami, kako odabrati poliranje paste, korisne savjete

- Trajnost motora, život motora, kako produžiti život motora

- Kucati u auto. Knock prilikom premještanja automobila. Što može kucati u autu. Kako odrediti uzrok kucanja.

- ABS Car, što je ABS CAR, ABS sustav kvar, ABS dijagnostika

- Pretjecanje automobila kada možete početi pretjerivati \u200b\u200bautomobil, pravila prometnih pravila

- Pumpa za gorivo VAZ 2110, VZ 2110 Shema benzinske postaje, VZ 2110 uređaja za pumpe za gorivo, VAZ 2110 Popravak benzinske postaje,

- Automobilske antene za radio, automobilsku antenu, auto antene to učiniti sami

- Prednji suspenzija Kalina, prednja suspenzija uređaja Kalina, kucanje u prednjoj suspenziji Kalina, popravak prednjeg ovjesa Kalina

- Ulje za apsorpciju udara, najbolje apsorberi ulja za ulje, pumpanje ulja amortizeri, kako pravilno pumpati uljni amortizer

- Kvačilo kvačilo, dodiruje kvačilo, uzrokuje kvačilo kvačilo, kako eliminirati

Komentari