Pojas mehanizma distribucije plina je nezamjenjiv atribut za najmodernije vozila, uključujući i za Chevrolet Lacetti automobil. Unatoč izvanrednoj jednostavnosti, to je vrlo važan detalj za motor s unutarnjim izgaranjem. Zamjena razvodnog remena na Chevroletu Lacetti - događaj je prilično dugotrajan, ali je potpuno jednostavan, ako točno djeluje ispod navedenih uputa.

Sadržaj

- Timing remen, koje zadatke rade remen vremena

- Vremenski remen, kao što radi i iz kojeg materijala

- Koliko često mijenja pojas za mjerenje vremena

- Koliko će promijeniti vremenski pojas, koji znakovi govore o potrebi za zamjenom razvodnog remena

- Slomio je mjerač vremena, što dovodi takav slom

- Vremenski remen, zašto je zamjena pojasa bolje u setu

- Alati, uređaji, potrošni materijal

- Sigurnosna tehnika

- Zamjena vremenskog remena Chevrolet lacetti, korak po korak rad

- Savjeti Profi, kako provjeriti napetost razvodnog pojasa

Timing remen, koje zadatke rade remen vremena

Zadatak je da se bregasto vratilo okreće brzinom, upravo identična polovica prometa radilice. Prije pola stoljeća, u automobilskoj industriji korištena je grm lanca, a svi pokušaji prilagodbe pojasa za to su nesporazum. Mnogo je vrijeme prošlo prije nego što je nastanak pojasa počeo dominirati. Ali ima nekoliko značajnih prednosti - pojednostavljujući dizajn, nisku razinu buke i smanjenje mase jedinice za napajanje.

Danas proizvođači radije instaliraju pogone remena na automobile. Ali nedvosmisleno je nedvosmisleno reći da je lanac gori od pojasa. Lanac pogon također ima svoju prednost - trajnost, korelirana s trajanjem samog motora. Stoga, čak iu naše vrijeme, neke proizvodne tvrtke zaustavljaju svoj izbor na mehanizmu lanca. Osim toga, takvi motori su obično opremljeni automatskim zatezačima. Životni vijek običnog remena vrlo rijetko prelazi 60 tisuća kilometara, a jednostavnost dizajna podrazumijeva potrebu za trajnom uslugom - pull-up, zamjena, kontrolu nad statusom pojasa.

Vremenski remen, kao što radi i iz kojeg materijala

Da bi mjerni remen pouzdano radio, moraju se promatrati sljedeći uvjeti - optimalno stanje remenica i valjaka uz koje se pojas pomiče, ispravno napetost remena, njegova apsolutna zaštita od nafte i prljavštine. Dizajn pojasa je vrlo jednostavan i nešto sliči gumu automobila.

Stoga se većina tvrtki koje specijaliziraju za proizvodnju gume također proizvode pojaseve. Temelj razvodnog remena - kabel - pleksus izdržljivih niti iz stakloplastike. Unutarnji kabeli su zubi od materijala otpornih na habanje (u pravilu, najlon), a izvan njega štiti sloj gume, čija je debljina oko pet milimetara. Dizajn pojaseva je prilično raznolik. Može se razlikovati u širini pojasa, broj i korak zuba, kao i njihov profil (postoji oko dvadeset vrsta profila zuba).

Koliko često mijenja pojas za mjerenje vremena

Zamjena mjernog remena na Chevroletu Lacetti, prema propisima o održavanju, potrebno je provesti svakih 60.000 kilometraža kilometraža. Međutim, većina stručnjaka preporučuje smanjenju promjene u razdoblju zamjene zbog složenih radnih uvjeta. Što se tiče provjere stanja pojasa, tada se na automobilu Chevrolet Lacetta treba provesti svakih 30 tisuća kilometara.

Koliko će promijeniti vremenski pojas, koji znakovi govore o potrebi za zamjenom razvodnog remena

- Noseći materijal. Timing remen je u stanju istrošiti na isti način kao, na primjer, guma. Ako se materijal pojasa nosi, može se pojaviti da biste ga otvorili ili klizeli. Pogotovo često se to događa na velikim opterećenjima na motoru motora. Na primjer, kada prate prikolicu ili prikolicu, kao i u mokro vrijeme.

- Abrazija remena. To se događa, u pravilu, s odstupanjem remenice i zatezača iz stražnjeg položaja, kao i kada je ne kvar ležaja i povišena temperatura. U slučaju inspekcije, možete primijetiti trošenje zubi pojasa - njezinu bazu tkiva (dilatirana tkanina i neravnomjerna tekstura).

- Odvajanje ili pukotine. Ova značajka zaliha je očita. Potrebno je istražiti stražnju i prednju površinu pojasa. Prisutnost pukotina, osobito ako ih ima mnogo, ukazuje na jak istrošen.

- Stvrdnjavanje suprotne površine zupčanog pojasa je suprotna površina pojasa teška, a ne elastična i sjaj. U ovom slučaju pojas postaje neumjestan, zbog čega više ne daje željeni kontakt s remenom.

- Izduženost. Materijalna trošenje je sposobna voditi snažnu izduženje pojasa, kao rezultat toga napetost valjak prelazi izvan dopuštenih granica. Time se smanjuje rigidnost i ukupna napetost remena, a time i ukupni rad mehanizma.

- Odstupanje od određenog položaja. Ova značajka pokazuje da su unutarnji elementi valjka za zatezanje prilično blizu lom. Ako valjak ne uspije, to će dovesti do povećane buke, temperature i vibracija.

Slomio je mjerač vremena, što dovodi takav slom

Pad vremenskog pojasa može podrazumijevati masu neugodnih posljedica koje se razlikuju, u rasponu od potrebe za zamjenom razvodnog remena i obnovite mehanizam za distribuciju plina i remont motora.

Najteža situacija je kada je ventil savijen kao rezultat prekida pojasa. To se jednostavno objašnjava. Jaz se može dogoditi u razdoblju kada su ventili pali na ubrizgavanje goriva ili oslobađanje plinova. U isto vrijeme, kretanje klipova u cilindrima i dalje se nastavlja i mogu ih pogoditi iz svih sile. U ovom slučaju, "sastanak" može završiti prilično loše.

Procijenite stupanj oštećenja može se ocijeniti samo nakon demontaže glave motora i procijeniti stanje klipnog sustava i ventila. Treba napomenuti da defekt ventila ne može odmah vidjeti - za dijagnostiku zahtijeva posebnu opremu.

Vremenski remen, zašto je zamjena pojasa bolje u setu

Kako bi se izbjegli problemi u budućnosti, zamjena razvodnog remena je poželjno proizvesti zajedno s crpkama i valjcima. Međutim, to nije obvezno djelovanje, međutim, ako postoje dodatna sredstva, najbolje je ne biti lijen jer će utjecati na učinkovitost novog mjernog remena.

Osim toga, da biste ispunili zamjenu, morat ćete u potpunosti rastaviti sve komponente ove opreme, uključujući crpku s valjcima. Stoga zamjena potrošnog materijala trošak ovog postupka neće se povećati mnogo, a to neće potrajati mnogo vremena, ali će povećati vijek trajanja zamijenjenog agregata.

Alati, uređaji, potrošni materijal

- Glave na "10", "12", "14", "17", "32".

- Podesiv naglasak.

- Šesterokut na "5".

- Ključ za "41".

- PassionA.

Sigurnosna tehnika

Nemoguće je raditi pod vozilom ako se objavljuje samo na utičnici. Kao osiguranje u obveznom, koristite tvorničku stanicu. Zabranjeno je objesiti automobil na dva ili više priključaka. Da biste zaštitili ruke od modrice i reže s operacijama "Power", trebali biste raditi u rukavicama.

Zamjena vremenskog remena Chevrolet lacetti, korak po korak rad

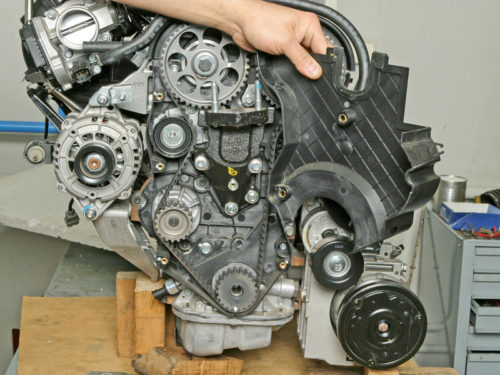

- Otvorite poklopac i demontirajte dekorativnu sluznicu s motorom, za koji trebate odvijati četiri matice.

- Radi praktičnosti, rastavite kućište filtra za zrak. Da bismo to učinili, s poklopcem filtra za zrak, odvratili smo četiri vijka, kao i kaput zračne mlaznice. Mi rastavljamo poklopac i filtar za zrak. Da biste uklonili samu kućište filtra, odvijte još dva vijaka.

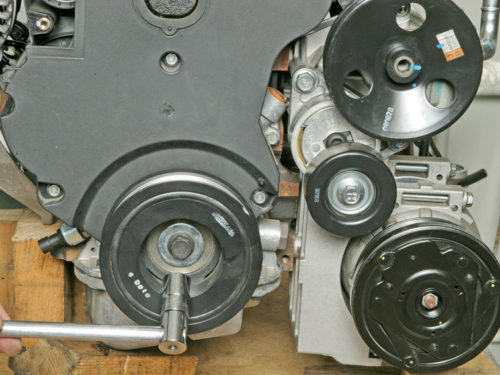

- Sada uklonite pogonski remen - povucite pogon valjak pomoću tipke na "17" i rastavite pojas iz remenica. Zatim biste trebali odvrnuti dva vijka i ukloniti gornji poklopac mjernog poklopca.

- Uklanjamo uklanjanje prednjeg desnog kotača i bočnog nasilja motora, koji je pričvršćen na tri klipove i dva vijka.

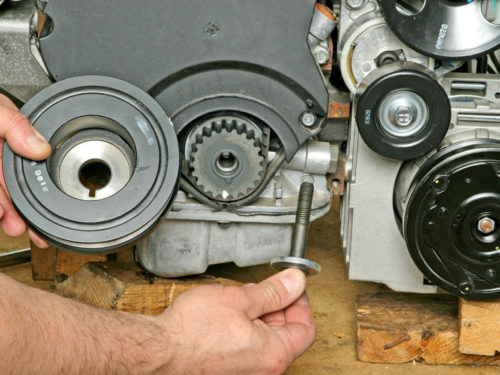

- Odvijemo remenicu radilice, za koju popravite zamašnjak pomoću velikih prorezanog odvijača kroz prozor gledanja. Zatim, s zavarivačem i glavom na "17" odvijali smo se i rastavljamo remenicu radilice.

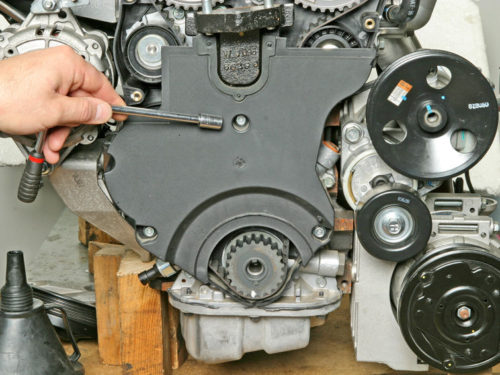

- Također biste trebali ukloniti donji poklopac mjerač vremena, koji je pričvršćen za tri cogs.

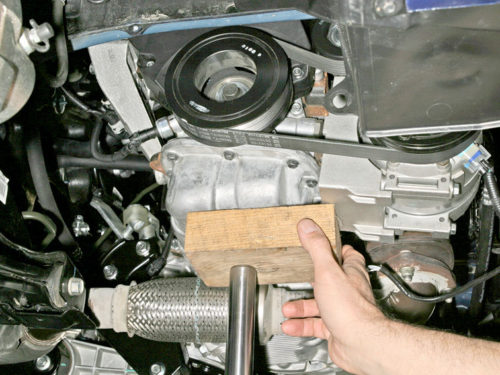

- Sljedeći korak je ukloniti podršku motora, za ono što trebate instalirati dodatnu priključnicu za jedinicu za napajanje ispod palete. Tada smo odvratili 3 matice i 1 vijak pomoću ključa za "14" i rastavljajte potporu OB.

- Odvijemo četiri vijka oko perimetra nosača za podršku i uklonite nosač.

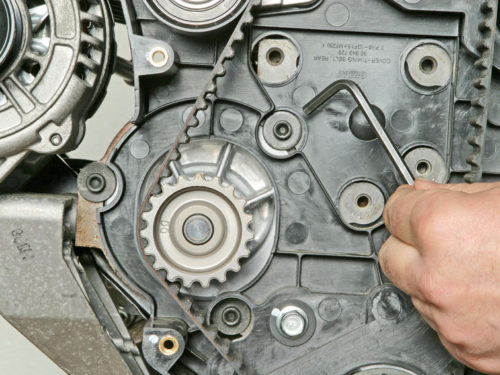

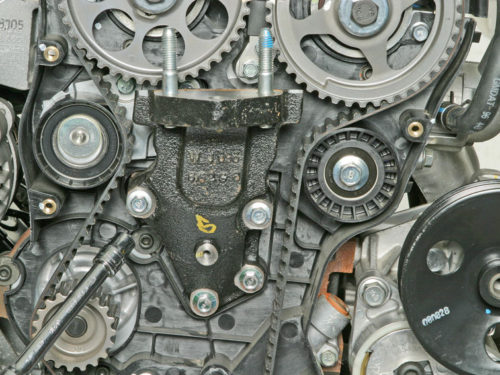

- Nadalje, na svim remenicama postavljamo vremenske oznake. Na remenici radilice bit će ispod.

- Za praktičnost rotacije radilice, zategnite vijak remenice natrag.

- Sada nastavite s zamjenom razvodnog remena. Koristeći ključ za "14", odvratiti parazitski valjak, koji se nalazi na desnoj strani i rastavljajući pojas, nakon čega odvrnumo zatezač valjaka, koji je pričvršćen za tri vijka.

- Prije montaže pojasa provjerite oznake, jer nakon uklanjanja mogu biti srušeni.

- Kada ostane samo da nosite pojas na crpki, pomaknite zatezač valjka, nakon čega je do kraja pojasa i provjerio instalaciju naljepnica.

- Zatim pomaknite radilicu u smjeru kazaljke na satu na jednom ili dva okreta i ponovno provjerite naljepnice.

Savjeti Profi, kako provjeriti napetost razvodnog pojasa

Da biste provjerili napetost razvodnog remena, okrenite radilicu dva do tri puta u smjeru kazaljke na satu i pogledajte zube za zatezača. Potrebno je da su međusobno stajali nasuprot - plus minus nekoliko milimetara. Ako se očitanja razlikuju, morat ćete podesiti napetost pojasa pomoću crpki.

Povezani materijali

- Peć 2110, loš topli štednjak 2110, VZ 2110 Sustav grijanja, popravak sustava grijanja VAZ 2110 vlastitim rukama

- VAZ 2114 štednjak puše s hladnim zrakom, štednjak 2114, loš topli štednjak vaz 2114, uređaj i popravak grijanja VAZ 2114 do-it-yourself, uklanjanje štednjak VAZ 2114

- Kako subdominatizirati automobil. Kako staviti utičnicu. Vrste priključnica za automobile.

- VAZ 2109 Blok osigurača, VZ 2109 Blok osigurača, VZ 2109 Blok osigurača Blok, stari VAZ 2109 Blok osigurača, VAZ 2109 osigurač blok, vaz osigurač blok 2109

- Katalizator ispušnih plinova automobila, neispravan katalizator, pluse i mane katalizatora, kako promijeniti katalizator na ramencitel

- Štednjak puhanje hladnog zraka vaz 2114, loše puhanje štednjak vaz 2114, zašto loše puše štednjak vaz 2114

- Kako saznati vlasnik automobila po broju automobila, provjeriti automobil po broju prometnog policijskog stroja, provjeriti automobil od strane državnog broja automobila besplatno

- Kako odabrati rabljene gume, korisne savjete

- Zimski automobil, tlak u putničkim automobilima zimi, dobru bateriju za automobil zimi, hoće li zimi zagrijati automobil

- Zimi je automobil slabo pokrenut. Kako napraviti auto zimi, trebate li zagrijati automobil zimi, korisne savjete

- Strojevi za potrošnju goriva u gospodarstvu, najekonomičniju potrošnju automobila

- Gume brandova za osobna vozila, označavanje označavanja guma automobila, zaostalo putničkog automobila zaštitnika guma, kako odabrati gumu na marku automobila, uzorak gaznoga sloja automobila

- Rad prijenosa Rad, mehanički mjenjač kvačilo, vožnja s ručnim mjenjačem, korisnim savjetima

- Stražnji snop peugeot 206 limuzi, stražnji snop peugeot 206. Stražnji snop Peugeot 206 kvarovi, popravak stražnjeg snopa Peugeot 206

- Dizel gorivo zimi, aditiv za dizelsko gorivo zimi, kako odabrati najbolje dizelsko gorivo

- Dizel zima ne počinje. Kako započeti dizel zimi, grijanje dizel zimi.

- Japanci Bridgestone gume, zimska okovana Bridgestone gume, brand Bridgestone gume

- Označavanje guma Dekodiranje za osobne automobile, označavanje kotača, kako odabrati desne gume na diskovima

- Dizelski motor zimi, pokretanje dizelskog motora zimi, što ulje popunjava dizelski motor zimi, korisni savjeti

- LED pozadinsko osvjetljenje automobila, pozadinsko osvjetljenje dna automobila, pozadinsko osvjetljenje nogu u automobilu, pozadinsko osvjetljenje na vratima automobila, pozadinsko osvjetljenje automobila je u redu

- Oporavljene gume, guma autobusa, obnovljena zaštitnica guma, mogu li ih koristiti

- Odaberite zimske gume, koje su zimske gume, koje tlak u zimskim gumama trebaju biti označene zimskim gumama, kako odabrati prave zimske gume, najbolje zimske gume 2019

- Upravljač željeznicom, kucanje upravljačkog stalka, razlozi za kucanje i popravak raka upravljača to čine sami

- Gume za automobile bez grešaka, skup za popravak guma bezbojnih, popravak gume bez topova

- Ruske gume, ruske gume zime, ruske cijele sezonske gume, Voronezh Amtel gume, gume "Matador Omsk guma", Kama-gume su svjetski razred autobus

- Kako otvoriti automobil bez ključa. Izgubio je ključ od automobila što učiniti, ključ od automobila unutar automobila

- Tihe gume, mirne zimske gume, miran sabirni autobus, koje gume biraju, pregledavaju gume

- Gume i sigurnost, sigurnost autobusa, zašto je potrebno stalno pratiti auto gume

- Pravila sigurnog vožnje automobila u kiši i bljuzganju, sigurna vožnja automobila za početnike

- Converter za hrđu koji je bolji za automobile, RUST pretvarači da biraju kako koristiti transducer za hrđu, profesionalce

- Poliranje tijela automobila to učiniti sami, kako odabrati poliranje paste, korisne savjete

- Trajnost motora, život motora, kako produžiti život motora

- Kucati u auto. Knock prilikom premještanja automobila. Što može kucati u autu. Kako odrediti uzrok kucanja.

- ABS Car, što je ABS CAR, ABS sustav kvar, ABS dijagnostika

- Pretjecanje automobila kada možete početi pretjerivati \u200b\u200bautomobil, pravila prometnih pravila

- Pumpa za gorivo VAZ 2110, VZ 2110 Shema benzinske postaje, VZ 2110 uređaja za pumpe za gorivo, VAZ 2110 Popravak benzinske postaje,

- Automobilske antene za radio, automobilsku antenu, auto antene to učiniti sami

- Prednji suspenzija Kalina, prednja suspenzija uređaja Kalina, kucanje u prednjoj suspenziji Kalina, popravak prednjeg ovjesa Kalina

- Ulje za apsorpciju udara, najbolje apsorberi ulja za ulje, pumpanje ulja amortizeri, kako pravilno pumpati uljni amortizer

- Kvačilo kvačilo, dodiruje kvačilo, uzrokuje kvačilo kvačilo, kako eliminirati

Komentari