Iskusni vozač uvijek se osjeća kao da se vozilo ponaša na cesti, a na temelju pojedinačnih značajki određuje koji se sustav dijagnosticira. Ako se nepravilnosti na cesti sve više osjećaju u carinoj kabini, najvjerojatnije je vrijeme za provjeru suspenzije ili njegove pojedinačne komponente. O tome dalje u članku.

Sadržaj

- Amortizer, uređaj i svrha

- Provjera amortizera, je li moguće podijeliti tijelo, moderno auto, provjeriti moć amortizera

- Amortizer ne radi koji nevolja ugrožava automobil i vozača ako nije uspio amortizer

- Provjera amortizera šok, kako provjeriti pomoć amortizera s vlastitim silama bez demontaže amortizera

- Kako provjeriti amortizer na performanse pomoću uređaja s senzorom pokreta

- Šok test (Shock-test) Dijagnostika amortizera udara

- Ekspresna dijagnostika amortizera

- Provjera opterećenja amplitude amplitude amortizatora

- Novi amortizeri, kako provjeriti amortizer na mjestu kupnje od prodavatelja

- Savjete prof.

Amortizer, uređaj i svrha

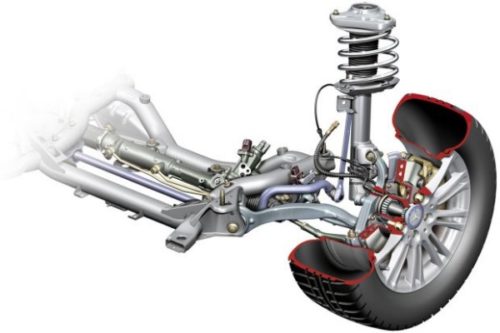

Amortizer je osmišljen kako bi se zaustavila padova i udaraca, kada se kreće prima tijelo automobila pomoću kotača. Osim toga, amortizeri osiguravaju pouzdanu vezu kotača vozila s roadpapers. Dakle, njihovo odredište nije samo utjeha, ali sigurnost.

Prije toga, automobili nisu bili opremljeni sa amortizerima. Njihove funkcije su provedena od strane izvora - napravljena za gašenje vibracija uslijed trenja od listova iz postali jedni od drugih. Brzina kojom automobili mogao kretati neprestano su rasle, kao rezultat od kojih je novi sustavi morali razviti za sigurnost i udobnost. Dakle, stalci postojala u obliku bloka komprimirani trenja diskova, koji su radili kako slijedi: Vibracije su zaustavljena na teret napora, s kojima Diskovi su rotirani u odnosu na drugu. Nakon nekog vremena, bilo je potrebno napustiti takav dizajn, jer diskovi su vrlo brzo nosio i pregrijan.

U 20-ih godina dvadesetog stoljeća, izlaz je pronađen. Rješenje problema je uporaba tekućine koja ima vibraciju tijela, koji se kreće iz jednog spremnika u drugi pod pritiskom.

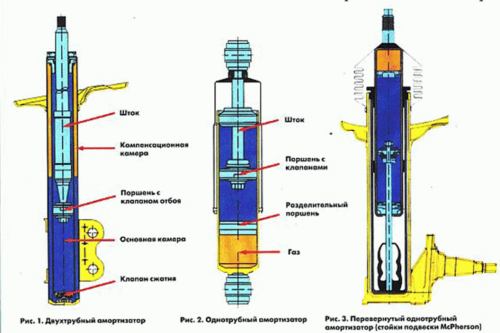

Po svom dizajnu, stalak se može podijeliti u nekoliko većih varijacija. U strukturi, one se, u pravilu, jedna cijev i dvije cijevi.

Amortizeri odlikuju vrsti tekućine koja se napuni plinom - (sa plinom hidraulički subpode) i hidraulički. Postoje samo plin amortizeri, ali oni koriste vrlo rijetko. Plin u njima je pod visokim tlakom (oko 60 atm).

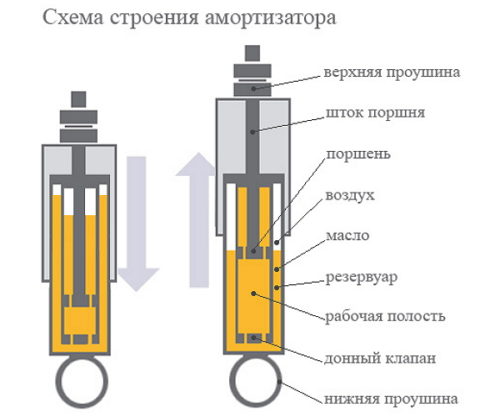

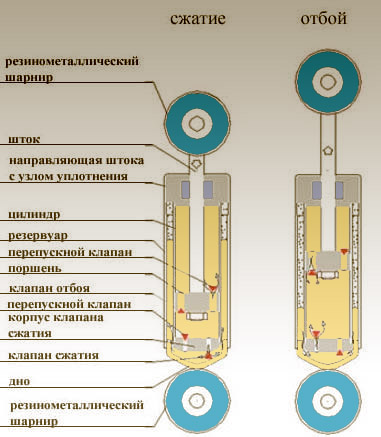

Rad amortizera je hidraulički otpor ili plin otpor. Ulje djeluje kao tekućina. Postoje vrste stalci u kojoj je, osim ulja, otpor daje cijeđenje i tlačna plin.

Amortizer sebi uvjetno je podijeljen u klipa i cilindra. Unutar cilindra, ovisno o modifikaciji, su komore - ili s plinom i maslaca ili zrakom i uljem. U oba slučaja, klip ide u cilindru, pada i diže. U drugom slučaju, klip se opire pritisak generira tlačne komore plina. U prvom - klipni kreće s otporom, koji se javlja kao posljedica protoka nafte pomoću ventila u drugu komoru.

Provjera amortizer, je li moguće podijeliti na tijelo, moderan auto, provjerite snagu amortizera

Ranije, na starim modelima klasičnih automobila s prošlih tipova i modela amortizera je mogućnost servisiranja polica može se odrediti vrlo jednostavan - uz pomoć gomile tijela. Kompleks dizajn moderne automobilske suspenzije ne dopušta vizualno napraviti objektivne zaključke o pomoći amortizera. Međutim, postoji mnogo drugih učinkovitih metoda koje ćemo razmotriti u nastavku.

Amortizer ne djelo koje nevolje ugroziti automobil i vozača ako je amortizer nije uspio

Glavna smetnja od amortizera je promjena u njihovim radnim parametrima, koji nastaje kao posljedica poremećaja u nepropusnost, mehanička oštećenja ili istrošenosti radnih elemenata (matičnih) od amortizera.

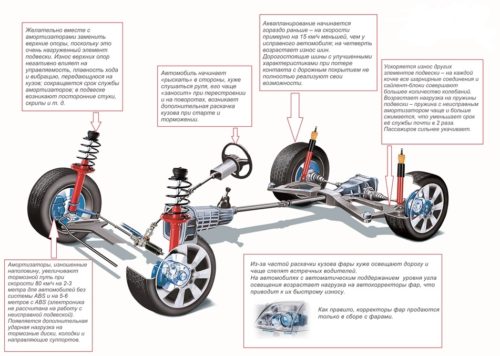

Kvar na amortizera dovodi do sljedećih posljedica:

- Povreda automobila upravljivosti. Sjeti se izraz „Nisam se nosi s kontrolom ...”. Neki vozači ponekad iznenadi - dobro, kako ga mogu nositi s njim? U stvari, sve je jednostavno: kada se okreće rotacija na brzinu, a neispravni amortizeri napravio automobil spontano kreće hrpu metala.

- Smanjenje nosivost.

- Smanjena nastavni stabilnost vozila.

- Povećanje put kočenja, rizik od „skrbi” na stranu sa ekstremnim ili srednje kočenja.

- Ubrzanje trošenja i kvarova takvih komponenti ovjesa, kao nosača police, izvora, tihe blokova, Hub ležajeva, shruches, i tako dalje.

- Pogoršanje udobnosti vožnje.

Provjera amortizer, kako provjeriti pomoć amortizera sa svojim vlastitim snagama bez rastavljanja amortizer

Vrlo je važno da se ova metoda može provjeriti samo pomoć amortizera, a ne njegovu učinkovitost. Korespondencija polica tehničkim karakteristikama proizvođača je zasebna razgovor.

Možete neovisno provjeriti pomoć amortizera bez rastavljanja možete samo vizualno - dijagnosticirati prisutnost mehaničkih oštećenja (na primjer udubljenja) i dobrotu nepropusnost.

Ako se curi ulje i mrlje vidjeti na kućište amortizera, odmah izvući zaključak da su brtve istroše, što ukazuje na nastanak amortizera.

Ljudi postoji mišljenje da je ulje „magla” na slučaju je kvar, ali to nije. Kada je amortizer radi, ova tikvica smatra normalna pojava.

Pri obavljanju dijagnozu amortizera, nakon što je demontaža, potrebno je obratiti posebnu pozornost na štapu - to ne bi trebao biti jakne, tragovi korozije A, posebno deformacije.

Kako provjeriti amortizer na performanse korištenjem uređaja sa senzorom pokreta

Ovaj uređaj je „ručno”. To je priključen na krilo automobila, a senzor je stavio na zemlju. Tijelo naborano informacije proizvoditi. U isto vrijeme, tvornica parametri su uvedeni u uređaj, što su brzina amortizera. Performanse police se dijagnosticira kod postotni udio.

Šok Test (šok-test) Dijagnostika amortizera

Šok Test proizvedena na posebnom postolju. Kotači osi trebao biti podizanje i pad oštro. Računalo bilježi koeficijent slabljenja rack oscilacija.

Express dijagnostika amortizera

Express dijagnostika pruža oštru kočenje. To se provodi na stalku s posebnim platformama. U isto vrijeme, kočioni sustav provjerava. Automobil mora ući u platformu i kočnicu oštro. Oscilacije karoserije su fiksne, kao i opterećenja na senzorima platforme. Iako je točnost ove metode ostavlja puno da se željeni.

Provjera opterećenje amortizera amplitude-rezonantne način

Provjera amortizeri amplitude-rezonantne metoda se temelji na analizi amplitude (to jest, vrijednost pokreta) platforme s kotača vozila montirana na njega. Platforma je izvijestio oscilacije čija je frekvencija oko 16 Hz. Kao što se podaci oslabljena, oscilacije događa rezonanciju - povećanje amplitude oscilacija, kada je frekvencija fluktuacije platforme i vlastite frekvencije suspenzije vozila. Veće vrijednosti amplituda doseže, što je još gore gasi oscilacija amortizera. Dalje, stalak uspoređuje rezultata mjerenja s referentnim podacima, nakon čega izdaje zaključak o performansama amortizera.

Novi amortizeri, kako provjeriti amortizer na mjestu kupnje od prodavatelja

- Vanjska, vizualni pregled. Provjerite oznaka. Ona mora odgovarati kataloga proizvođača. Dalje, morate provjeriti amortizer za prisutnost raznih mehaničkih oštećenja žlijezda, stanovanje, šipke i tako dalje. Provjerite navojem veze. Naravno, ne bi trebalo biti inkluzije ulja.

- Provjera geometrijski sukladnosti. Potreban vam je čeljust i ravnalo. Potrebno je provjeriti duljinu u državi smjene, promjer klipa i klipnjače potez (orijentaciji ili na prijedlog proizvođača, odnosno odstupanja od nominalne vrijednosti - ± 5 mm).

- Provjera uspješnosti amortizera. Pojedinačna cijev se provjerava bez prethodne pripreme. Trebaju biti komprimirani i rastegnuti oko 3-5 puta. Šipka se mora glatko pomicati, bez oštrih udaraca i ometanja, s istim naporom. Osim prirodnog "prijedloga" ne bi trebalo biti stranih škripa i buke, što je rezultat protoka tekućine unutar stalka. Dual-cijev mora biti spremna unaprijed pripremiti - pumpati nekoliko puta (3-5), postavite okomito, nakon čega ne okreće amortizer.

Savjete prof.

Dijagnosticirajte probleme koji su povezani s radom amortizera šok je vrlo jednostavan - automobil se primjetno trese kad udari u izbočine, čuje se karakteristično tapkanje. Glavni problem povezan s dolaskom ovog uređaja u zapuštenost je da se taj proces događa postupno (iznimka je plinski i uljni amortizeri, koji su zbog svog dizajna, mogu odmah propasti). Dakle, vozač se može prilagoditi takvom ponašanju stroja i ne žuriti za popravak. Međutim, u međuvremenu, trošenje guma i staza kočenja se povećava, upravljač je gori. Možda vam se čini da su to male stvari, ali s druge strane, u hitnim slučajevima, kvar amortizera može značajno utjecati na njihov ishod.

Važno je napomenuti da je u prijevozu, koji je opremljen elektroničkim kočnim sustavima (EBD, ABS i tako dalje), neispravni amortizeri šok neće rijetko dovesti do slabosti neuspjeha.

Povezani materijali

- Peć 2110, loš topli štednjak 2110, VZ 2110 Sustav grijanja, popravak sustava grijanja VAZ 2110 vlastitim rukama

- VAZ 2114 štednjak puše s hladnim zrakom, štednjak 2114, loš topli štednjak vaz 2114, uređaj i popravak grijanja VAZ 2114 do-it-yourself, uklanjanje štednjak VAZ 2114

- Kako subdominatizirati automobil. Kako staviti utičnicu. Vrste priključnica za automobile.

- VAZ 2109 Blok osigurača, VZ 2109 Blok osigurača, VZ 2109 Blok osigurača Blok, stari VAZ 2109 Blok osigurača, VAZ 2109 osigurač blok, vaz osigurač blok 2109

- Katalizator ispušnih plinova automobila, neispravan katalizator, pluse i mane katalizatora, kako promijeniti katalizator na ramencitel

- Štednjak puhanje hladnog zraka vaz 2114, loše puhanje štednjak vaz 2114, zašto loše puše štednjak vaz 2114

- Kako saznati vlasnik automobila po broju automobila, provjeriti automobil po broju prometnog policijskog stroja, provjeriti automobil od strane državnog broja automobila besplatno

- Kako odabrati rabljene gume, korisne savjete

- Zimski automobil, tlak u putničkim automobilima zimi, dobru bateriju za automobil zimi, hoće li zimi zagrijati automobil

- Zimi je automobil slabo pokrenut. Kako napraviti auto zimi, trebate li zagrijati automobil zimi, korisne savjete

- Strojevi za potrošnju goriva

- Gume brandova za osobna vozila, označavanje označavanja guma automobila, zaostalo putničkog automobila zaštitnika guma, kako odabrati gumu na marku automobila, uzorak gaznoga sloja automobila

- Rad prijenosa Rad, mehanički mjenjač kvačilo, vožnja s ručnim mjenjačem, korisnim savjetima

- Stražnji snop peugeot 206 limuzi, stražnji snop peugeot 206. Stražnji snop Peugeot 206 kvarovi, popravak stražnjeg snopa Peugeot 206

- Dizel gorivo zimi, aditiv za dizelsko gorivo zimi, kako odabrati najbolje dizelsko gorivo

- Dizel zima ne počinje. Kako započeti dizel zimi, grijanje dizel zimi.

- Japanci Bridgestone gume, zimska okovana Bridgestone gume, brand Bridgestone gume

- Označavanje guma Dekodiranje za osobne automobile, označavanje kotača, kako odabrati desne gume na diskovima

- Dizelski motor zimi, pokretanje dizelskog motora zimi, što ulje popunjava dizelski motor zimi, korisni savjeti

- LED pozadinsko osvjetljenje automobila, pozadinsko osvjetljenje dna automobila, pozadinsko osvjetljenje nogu u automobilu, pozadinsko osvjetljenje na vratima automobila, pozadinsko osvjetljenje automobila je u redu

- Oporavljene gume, guma autobusa, obnovljena zaštitnica guma, mogu li ih koristiti

- Odaberite zimske gume, koje su zimske gume, koje tlak u zimskim gumama trebaju biti označene zimskim gumama, kako odabrati prave zimske gume, najbolje zimske gume 2019

- Upravljač željeznicom, kucanje upravljačkog stalka, razlozi za kucanje i popravak raka upravljača to čine sami

- Gume za automobile bez grešaka, skup za popravak guma bezbojnih, popravak gume bez topova

- Ruske gume, ruske gume zime, ruske cijele sezonske gume, Voronezh Amtel gume, gume "Matador Omsk guma", Kama-gume su svjetski razred autobus

- Kako otvoriti automobil bez ključa. Izgubio je ključ od automobila što učiniti, ključ od automobila unutar automobila

- Tihe gume, mirne zimske gume, miran sabirni autobus, koje gume biraju, pregledavaju gume

- Gume i sigurnost, sigurnost autobusa, zašto je potrebno stalno pratiti auto gume

- Pravila sigurnog vožnje automobila u kiši i bljuzganju, sigurna vožnja automobila za početnike

- Converter za hrđu koji je bolji za automobile, RUST pretvarači da biraju kako koristiti transducer za hrđu, profesionalce

- Poliranje tijela automobila to učiniti sami, kako odabrati poliranje paste, korisne savjete

- Trajnost motora, život motora, kako produžiti život motora

- Kucati u auto. Knock prilikom premještanja automobila. Što može kucati u autu. Kako odrediti uzrok kucanja.

- ABS Car, što je ABS CAR, ABS sustav kvar, ABS dijagnostika

- Pretjecanje automobila kada možete početi pretjerivati \u200b\u200bautomobil, pravila prometnih pravila

- Pumpa za gorivo VAZ 2110, VZ 2110 Shema benzinske postaje, VZ 2110 uređaja za pumpe za gorivo, VAZ 2110 Popravak benzinske postaje,

- Automobilske antene za radio, automobilsku antenu, auto antene to učiniti sami

- Prednji suspenzija Kalina, prednja suspenzija uređaja Kalina, kucanje u prednjoj suspenziji Kalina, popravak prednjeg ovjesa Kalina

- Ulje za apsorpciju udara, najbolje apsorberi ulja za ulje, pumpanje ulja amortizeri, kako pravilno pumpati uljni amortizer

- Kvačilo kvačilo, dodiruje kvačilo, uzrokuje kvačilo kvačilo, kako eliminirati

Komentari