Cureaua mecanismului de distribuție a gazului este un atribut indispensabil pentru cele mai moderne vehicule, inclusiv pentru mașina Chevrolet Lacetti. În ciuda simplității restante, acesta este un detaliu destul de important pentru motorul de combustie internă. Înlocuirea cureaua de distribuție pe Chevrolet Lacetti - evenimentul este destul de consumator de timp, dar este complet simplu, dacă acționați exact sub instrucțiunile furnizate.

Conţinut

- Cureaua de distribuție, ce sarcini fac centura de distribuție

- Cureaua de distribuție, așa cum funcționează și din ce material

- Cât de des schimba centura de distribuție

- Cât de mult pentru a schimba centura de distribuție, ce semne vorbesc despre necesitatea de a înlocui centura de distribuție

- A rupt centura de distribuție, care conduce o astfel de defalcare

- Cureaua de distribuție, de ce înlocuirea centurii este mai bună de făcut în set

- Instrumente, Luminări, Consumabile

- Tehnica de siguranță

- Înlocuirea curelei de distribuție Chevrolet Lacetti, pas cu pas de lucru

- Sfaturi Profi, cum să verificați tensiunea curelei de distribuție

Cureaua de distribuție, ce sarcini fac centura de distribuție

Sarcina este că arborele cu came se rotește la o viteză, exact jumătate identică a cifrei de afaceri a arborelui cotit. Acum o jumătate de secol, cu lanțul GRM a fost folosit în industria automobilelor, iar toate încercările de a adapta centura pentru aceasta au fost neînțelegeri. A trecut mult timp înainte ca Drive Belt să domine. Dar are mai multe avantaje semnificative - simplificând designul, zgomotul scăzut și o scădere a masei unității de alimentare.

Astăzi, producătorii preferă să instaleze curea pe mașinile lor. Dar este imposibil să spunem fără echivoc că lanțul este mai rău decât centura. Unitatea de lanț are, de asemenea, avantajul său - durabilitate, corelată cu durata motorului în sine. Prin urmare, chiar și în timpul nostru, unele companii de producție își opresc alegerea pe mecanismul lanțului. În plus, aceste motoare sunt, de obicei, echipate cu tensionatoare automate. Durata de viață a centurii obișnuite este foarte rar depășește 60 de kilometri, iar simplitatea designului implică necesitatea unui serviciu permanent - tragere, înlocuire, control asupra stării centurii.

Cureaua de distribuție, așa cum funcționează și din ce material

Pentru ca centura de distribuție să funcționeze în mod fiabil, trebuie respectate următoarele condiții - starea optimă a roților și a rolelor de-a lungul căreia centura este deplasată, tensiunea corectă a centurii, protecția absolută împotriva uleiului și murdăriei. Designul centurii este destul de simplu și ceva seamănă cu o anvelopă de mașină.

Prin urmare, majoritatea companiilor care se specializează în producția de anvelope produc și curele. Baza curelei de distribuție - Cord - Plexus de fire durabile din fibră de sticlă. Cablurile interioare sunt un dinți din materiale rezistente la uzură (de regulă, nailon) și exterior protejează stratul de cauciuc, grosimea căreia este de aproximativ cinci milimetri. Designul curelelor este destul de diversificat. Poate să difere în lățimea centurii, numărul și pasul dinților, precum și profilul lor (există aproximativ douăzeci de tipuri de profile din dinți).

Cât de des schimba centura de distribuție

Înlocuirea centurii de distribuție pe Chevrolet Lacetti, conform reglementărilor de întreținere, este necesar să se efectueze la fiecare 60.000 kilometri kilometri. Cu toate acestea, majoritatea specialiștilor recomandă reducerea schimbării perioadei de înlocuire datorită condițiilor complexe de funcționare. În ceea ce privește verificarea stării centurii, atunci pe mașină Chevrolet Lacetta ar trebui să fie efectuată la fiecare 30 de kilometri.

Cât de mult pentru a schimba centura de distribuție, ce semne vorbesc despre necesitatea de a înlocui centura de distribuție

- Material de purtare. Cureaua de distribuție este capabilă să poarte la fel ca, de exemplu, anvelopă. Dacă materialul curelei este uzat, poate să apară pentru ao deschide sau alunecare. Mai ales adesea acest lucru se întâmplă la încărcături mari pe motorul motorului. De exemplu, atunci când trageți o remorcă sau o remorcă, precum și la vreme umedă.

- Abraziunea curelei. Acest lucru se întâmplă, de regulă, cu abaterea scripetei și a rolei de tensionare din poziția din spate, precum și atunci când disfuncția lagărului și temperatura ridicată. În caz de inspecție, puteți observa uzura dinților curelei - baza de țesut (fibre de țesături dilatate și textura neuniformă).

- Detașarea sau fisurile. Această caracteristică a îngrijorării este evidentă. Este necesar să explorați suprafața din spate și din față a centurii. Prezența fisurilor, mai ales dacă există multe dintre ele, indică o puternică purtată.

- Întărirea suprafeței opuse a centurii dințate este suprafața opusă a centurii este greu, nu elastică și sclipitoare. În acest caz, centura devine neschimbată, ca rezultat că nu mai furnizează contactul dorit cu scripetele.

- Elongaţie. Purtarea materialului este capabilă să conducă o alungire puternică a centurii, ca urmare a căreia cilindrul de tensiune se deplasează dincolo de limitele admise. Acest lucru reduce rigiditatea și tensiunea totală a centurii și, în consecință, performanța generală a mecanismului.

- Abaterea din poziția desemnată. Această caracteristică indică faptul că elementele interne ale rolei de tensionare sunt destul de aproape de rupere. Dacă rola nu reușește, aceasta va duce la creșterea zgomotului, temperaturii și vibrațiilor.

A rupt centura de distribuție, care conduce o astfel de defalcare

Crashul centurii de distribuție poate implica o masă de consecințe neplăcute care sunt diferite, variind de la necesitatea de a înlocui centura de distribuție și pentru a restabili mecanismul de distribuție a gazelor și revizia motorului.

Cea mai dificilă situație este atunci când supapa este îndoită ca urmare a spargerii centurii. Acest lucru este explicat pur și simplu. Diferența se poate întâmpla în perioada în care supapele au scăzut la injectarea combustibilului sau la eliberarea gazelor. În același timp, mișcarea pistoanelor din cilindri continuă încă și ei sunt capabili să le lovească de toată forța. În acest caz, "întâlnirea" se poate încheia destul de rău.

Estimarea gradului de deteriorare poate fi evaluată numai după dezmembrarea capului motorului și estimarea stării sistemului de piston și a supapelor. Trebuie remarcat faptul că defectul supapei nu poate vedea imediat - pentru diagnosticare necesită echipamente speciale.

Cureaua de distribuție, de ce înlocuirea centurii este mai bună de făcut în set

Pentru a evita problemele în viitor, înlocuirea benzii de distribuție este de dorit să se producă împreună cu pompele și rolele. Aceasta nu este o acțiune obligatorie, cu toate acestea, dacă există fonduri suplimentare, cel mai bine nu este leneș, deoarece va afecta eficiența noii centuri de distribuție.

În plus, pentru a îndeplini înlocuirea, va trebui să dezasamblați pe deplin toate componentele acestui echipament, inclusiv pompa cu role. Astfel, înlocuirea consumabilelor Costul acestei proceduri nu va crește prea mult și nu va dura mult timp, dar va crește durata de viață a agregatului înlocuit.

Instrumente, Luminări, Consumabile

- Capete pe "10", "12", "14", "17", "32".

- Accent ajustabil.

- Hexagon pe "5".

- Cheia la "41".

- Passatia.

Tehnica de siguranță

Este imposibil să lucrăm sub vehicul dacă este postat numai pe mufa. Ca asigurare la obligatoriu, utilizați stația de stare din fabrică. Este interzis să atârnați mașina pe două sau mai multe mufă. Pentru a vă proteja mâinile de la vânătăi și tăieri cu operațiuni de "putere", ar trebui să lucrați în mănuși.

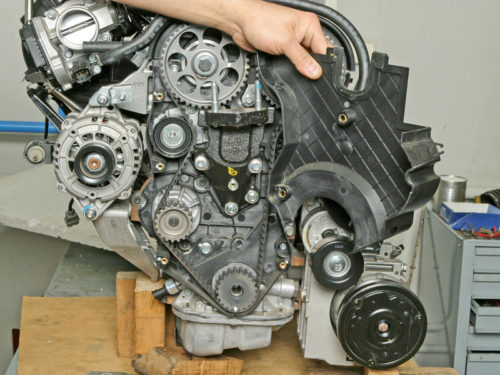

Înlocuirea curelei de distribuție Chevrolet Lacetti, pas cu pas de lucru

- Deschideți capota și demontați o căptușeală decorativă cu un motor, pentru care trebuie să deșurubați patru nuci.

- Pentru confort, dezmembrați carcasa filtrului de aer. Pentru a face acest lucru, cu capacul filtrului de aer, deșurubați cele patru șuruburi, precum și stratul de duză de aer. Demontați capacul și filtrul de aer. Pentru a elimina carcasa filtrului, deșurubați încă două șuruburi.

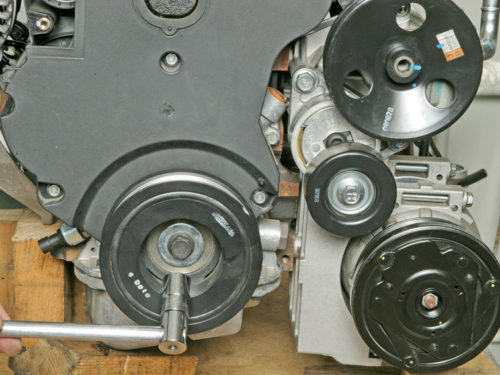

- Acum scoateți centura de transmisie - Trageți rola de antrenare utilizând tasta la "17" și dezmembrați centura de pe scripeți. Apoi, ar trebui să deșurubați două șuruburi și să scoateți capacul superior al capacului de sincronizare.

- Facem îndepărtarea roții din dreapta față și a anterului lateral al motorului, care este atașat la trei pistoane și două șuruburi.

- Deșururăm scripetele arborelui cotit, pentru care fixați volantul utilizând o șurubelniță mare prin fereastra de vizualizare. Apoi, cu un sudor și capul pe "17", deșurubați și dezmembrați scripetele arborelui cotit.

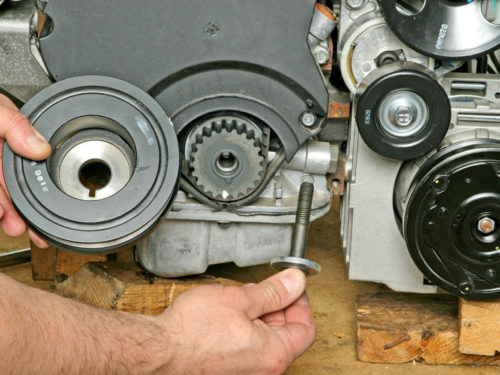

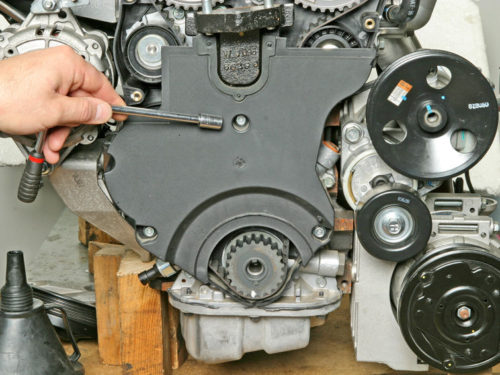

- De asemenea, trebuie să scoateți capacul inferior al centurii de distribuție, care este atașat de trei cogs.

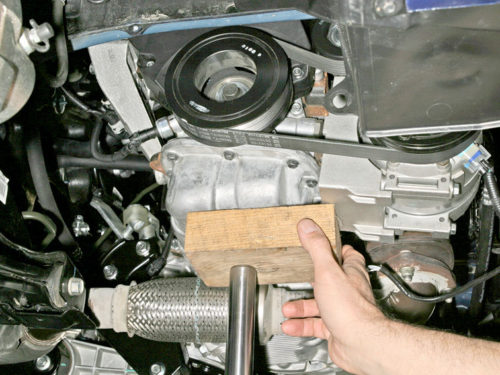

- Următorul pas este eliminarea suportului motorului, pentru ceea ce trebuie să instalați o mufă suplimentară pentru o unitate de alimentare sub palet. Apoi, deșurubăm 3 nuci și 1 șurub folosind cheia la "14" și dezmembrați suportul OBS.

- Deșururăm cele patru șuruburi din jurul perimetrului suportului de susținere și scoatem suportul.

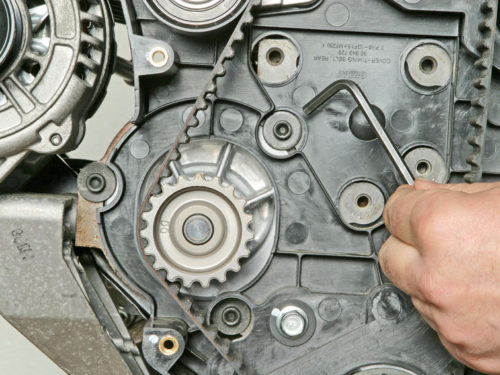

- Mai mult, pe toate scripetele, am stabilit etichetele de sincronizare. Pe scripetele arborelui cotit va fi mai jos.

- Pentru comoditatea rotației arborelui cotit, strângeți șurubul roții înapoi.

- Acum continuați să înlocuiți centura de distribuție. Folosind cheia la "14", deșurubăm rola parazitară, care este situată în partea dreaptă și dezmembra centura, după care deșurubăm dispozitivul de tensionare a rolelor, care este atașat de trei șuruburi.

- Înainte de a monta centura, verificați etichetele, deoarece după îndepărtarea ar putea fi lovită.

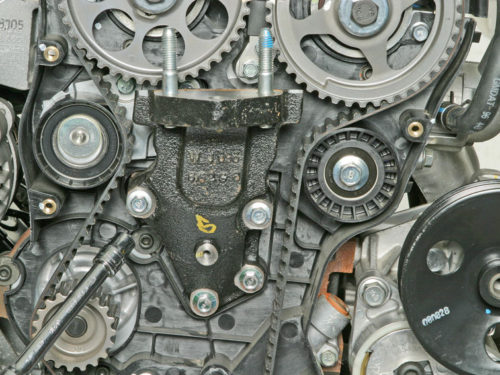

- Când rămâne doar pentru a purta o centură pe pompă, deplasați dispozitivul de tensionare a rolei, după care este de până la capătul centurii și verificați instalarea etichetelor.

- Apoi, defilați arborele cotit în sensul acelor de ceasornic pe unul sau două rotiri și verificați din nou etichetele.

Sfaturi Profi, cum să verificați tensiunea curelei de distribuție

Pentru a verifica tensiunea cureaua de distribuție, rotiți arborele cotit de două până la trei ori în sensul acelor de ceasornic și uitați-vă la dinții cu role de tensionare. Este necesar ca ei să se oprească unul pe altul - plus-minus câteva milimetri. Dacă citirile diferă, va trebui să reglați tensiunea curelei utilizând pompele.

Materiale similare

- Aragaz 2110, aragazul cald Bad 2110, sistemul de încălzire VAZ 2110, repararea sistemului de încălzire VAZ 2110 cu mâinile lor

- VAZ 2114 Apat lovituri cu aer rece, aragaz 2114, aragaz rău VAZ 2114, dispozitiv și reparații de încălzire VAZ 2114 Do-It-Yourself, eliminând soțul VAZ 2114

- Cum să subdominizați mașina. Cum să puneți un cric. Tipuri de mufă pentru mașini.

- VAZ 2109 Bloc de siguranțe, VAZ 2109 Carburator de blocuri de siguranțe, VAZ 2109 Injector de blocuri de siguranțe, Bloc de siguranțe VAZ 2109, bloc de siguranțe VAZ 2109, bloc de siguranțe VAZ 2109

- Catalizatorul de gaz de evacuare auto, catalizator defect, pluses și contra catalizatorului, cum să schimbați catalizatorul pe planegen

- Aragazul care suflă aerul rece VAZ 2114, suflă prost aragazul VAZ 2114, de ce suflă rău aragazul VAZ 2114

- Cum să aflați proprietarul mașinii cu numărul mașinii sale, verificați mașina cu numărul mașinii de poliție de trafic, verificați mașina cu numărul de stat al mașinii gratuit

- Cum de a alege anvelope uzate, sfaturi utile

- Drumul auto de iarnă, presiunea anvelopelor de autoturisme în timpul iernii, o baterie bună pentru mașină în timpul iernii, fie să încălzească mașina în timpul iernii

- În timpul iernii, mașina este pornită prost. Cum să faci o mașină în timpul iernii, trebuie să încălzi mașina în timpul iernii, sfaturi utile

- Consumul de combustibil pentru economie, consumul cel mai economic de mașini

- Branduri de anvelope pentru autoturisme, etichetare de etichetare a anvelopelor auto, protector de pasageri reziduale pentru autoturisme, cum să alegeți o anvelopă pe o marcă de mașini, model de treaptă de autoturism

- Funcționarea transmisiei de lucru, lucrarea ambreiajului mecanic, conducerea cu cutie de viteze manuală, sfaturi utile

- Beam din spate Peugeot 206 Sedan, Dispozitiv de fascicul din spate Peugeot 206. Beam spate Peugeot 206 Defecțiune, Repararea Beamului din spate Peugeot 206

- Motorină în timpul iernii, aditiv pentru motorină în timpul iernii, cum să alegeți cel mai bun motorină

- Diesel iarna nu pornește. Cum să începeți motorina în timpul iernii, încălzirea motorinei în timpul iernii.

- Anvelope japoneze de bridgestone, iarnă anvelope Bridgestone, Bridgestone Anvelope Brand

- Decodarea marcajelor pentru autoturisme pentru autoturisme, roți de etichetare, cum să alegeți anvelopele potrivite pe discuri

- Motorul diesel în timpul iernii, lansarea motorului diesel în timpul iernii, ce ulei pentru a umple un motor diesel în timpul iernii, sfaturi utile

- Lansarea luminii de fund a mașinii, lumina de fundal a fundului mașinii, lumina de fundal a picioarelor din mașină, lumina de fundal a ușii mașinii, lumina de fundal a mașinii este bine

- Anvelopele recuperate, anvelopele de autobuz, protectorul de anvelope restaurate, pot să le folosesc

- Alegeți anvelopele de iarnă, care este o anvelope de iarnă, care presiunea în anvelopele de iarnă trebuie marcate cu anvelope de iarnă, cum să alegeți anvelopele de iarnă din dreapta, cele mai bune anvelope de iarnă 2019

- Rail feroviar de direcție, baterea rack-ului de direcție, motive pentru lovitura și reparația rack-ului de direcție Fă-o singură

- Anvelope automate de mașini, un set pentru repararea anvelope fără tub, repararea anvelopei fără tun

- Anvelope rusești, anvelope rusești de iarnă, rusești anvelope de sezon, anvelope Voronezh Amtel, anvelope "Matador Omsk anvelopă", Kama-anvelope sunt autobuz de clasă mondială

- Cum de a deschide o mașină fără o cheie. A pierdut cheia de la mașină ce să facă, cheia din mașină în interiorul mașinii

- Anvelope silențioase, anvelope de iarnă liniștite, autobuz liniștit, ce anvelope pentru a alege, anvelope de ansamblu

- Anvelope și siguranță, siguranță a autobuzului, de ce este necesar să monitorizați în mod constant anvelopele de mașini

- Reguli de conducere în condiții de siguranță a mașinii în ploaie și nămol, în condiții de siguranță a mașinii pentru începători

- Rust Converter care este mai bine pentru autoturisme, convertoare de rugină pentru a alege cum să utilizeze traductor de rugină, profesioniști

- Lustruirea corpului mașinii o face singur, cum să alegeți o pastă de lustruire, sfaturi utile

- Durabilitatea motorului, viața motorului, cum să extindeți viața motorului

- Bate în mașină. Bate când mutați mașina. Ce poate bate în mașină. Cum de a determina cauza baterii.

- ABS auto, ceea ce este masina ABS, defecțiunea sistemului ABS, diagnosticarea ABS

- Depășirea unei mașini când puteți începe să depășiți o mașină, regulile de reguli de trafic

- Pompă de combustibil VAZ 2110, Schema de benzină VAZ 2110, dispozitivul pompei de combustibil VAZ 2110, repararea benzinării VAZ 2110,

- Antenele auto pentru radio, dispozitiv de antenă auto, antena auto face-o singur

- Suspensie frontală Kalina, Suspensie frontală a dispozitivului Kalina, Knock în suspensie din față Kalina, Repararea suspensiei frontale Kalina

- Ulei de absorbție a șocurilor, cel mai bun amortizoare de șocuri de ulei, amortizoare de pompare a șocurilor, modul de pompare a uleiului de pompare corespunzător

- Ambreiajul defecțiunilor, atinge ambreiajul, cauzează o defecțiune a ambreiajului, cum să eliminați

Comentarii