Nozzle otomotif adalah perangkat yang bertanggung jawab untuk penyemprotan bahan bakar langsung di dalam ruang pembakaran. Hingga saat ini, ada beberapa modifikasi perangkat ini. Tentang ini lebih lanjut dalam artikel.

Isi

- Sistem injeksi bahan bakar, dari mana sistem injeksi terdiri dari

- Injeksi langsung atau untuk apa yang Anda butuhkan nozel di mesin

- Jenis nozzle dan tujuannya

- Nozzle elektromagnetik, perangkat dan prinsip kerja

- Nozzle bensin dalam konteksnya

- Nozzle diesel, nozel mesin diesel, perangkat dan prinsip operasi

- Piezoforun, perangkat

- Piezohoroforsunk, prinsip kerja

- Piezohoroforsunk, martabat

Sistem injeksi bahan bakar, dari mana sistem injeksi terdiri dari

Sistem bahan bakar terdiri dari elemen-elemen seperti itu:

- Umbi top.

- Tangki bahan bakar.

- Pompa bahan bakar.

- Filter bahan bakar.

- Perangkat untuk mencampur udara dan bahan bakar.

- Kontrol tekanan bahan bakar.

- Asupan Manifold.

- Penyaring udara.

- Sensor.

- Muffler dari suara gas buang.

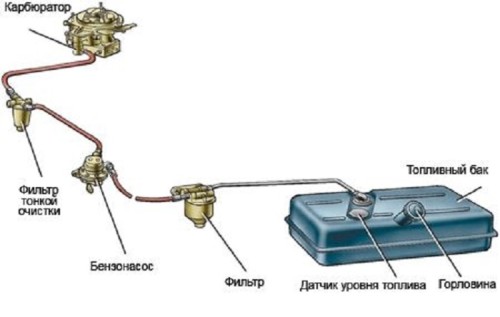

Tergantung pada perangkat yang digunakan untuk mencampur udara dan bahan bakar, ada tiga jenis sistem bahan bakar:

- Sistem bahan bakar yang dapat diisi ulang - digunakan di mesin diesel.

- Sistem bahan bakar karburator - digunakan dalam motor karburator.

- Sistem bahan bakar injektor - digunakan di mesin bensin. Dalam hal ini, untuk pencampuran udara dan bahan bakar bertanggung jawab atas nozzle.

Injeksi langsung atau untuk apa yang Anda butuhkan nozel di mesin

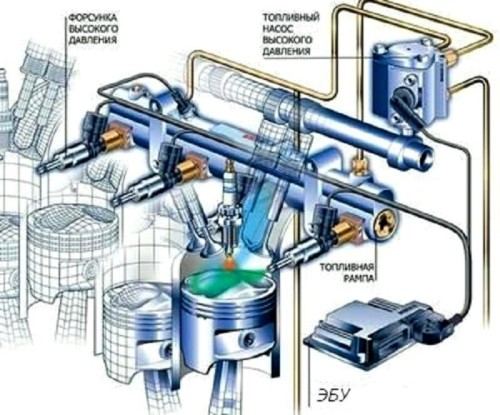

Injeksi langsung adalah modifulasi injeksi bahan bakar terdistribusi, di mana bahan bakar disuntikkan ke dalam silinder secara langsung. Nozzle adalah komponen pengikat utama antara pompa bahan bakar dan mesin. Tujuan utama nozel:

- Memastikan dosis bahan bakar yang benar dipasok ke motor.

- Memastikan jet yang benar (kuantitas, tekanan, sudut) campuran.

Jenis nozzle dan tujuannya

Nozzle elektromagnetik, perangkat dan prinsip kerja

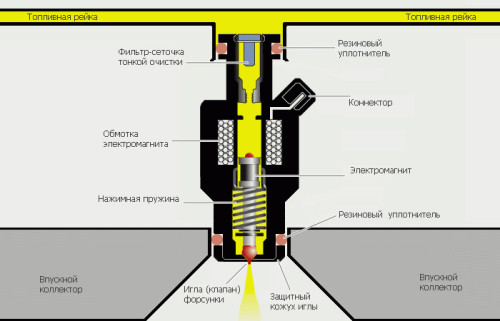

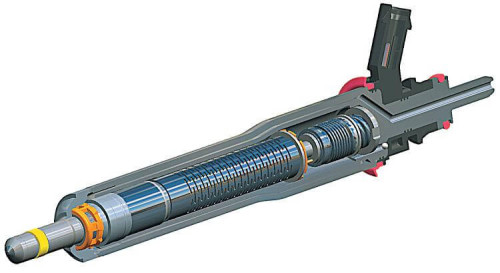

Perangkat elektromagnetik tersebut digunakan, sebagai aturan, pada mesin bensin, termasuk dengan injeksi langsung. Jenis peralatan ini memiliki desain yang cukup sederhana yang terdiri dari:

- Nozzle nozzle.

- Jarum.

- Segel pada kasing.

- Perumahan nosel.

- Jangkar dari elektromagnet.

- Musim semi khusus.

- Berliku eksitasi elektromagnetik.

- Konektor listrik.

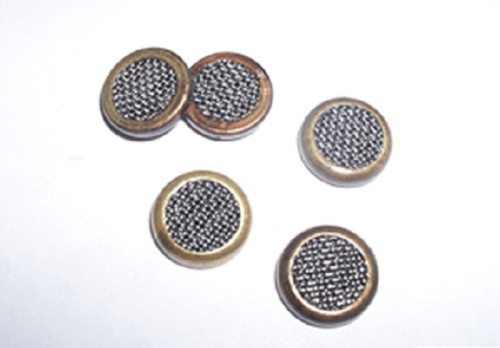

- Filter mesh.

Nozzle melakukan percikan bahan bakar. Dari kualitas pengoperasian komponen ini tergantung pada operasi seluruh perangkat. Filter mesh menyaring bahan bakar yang melewati nozzle.

ECU, sesuai dengan algoritma yang sebelumnya diletakkan, pada saat yang diperlukan memastikan pasokan voltase ke belitan eksitasi katup. Dalam proses ini, medan elektromagnetik terjadi, mengatasi kekuatan pegas, setelah itu menunda jangkar dengan jarum, yang membebaskan nozzle. Setelah semua ini adalah injeksi bahan bakar. Ketika tegangan menghilang, jarum nozzle kembali ke sadel menggunakan pegas.

Nozzle bensin dalam konteksnya

- Filter mesh.

- Nozzle nozzle.

- Segel.

- Nozzle jarum.

- Perumahan nosel.

- Jangkar elektromagnet.

- Harness berliku.

- Musim semi.

- Konektor listrik.

Nozzle diesel, nozel mesin diesel, perangkat dan prinsip operasi

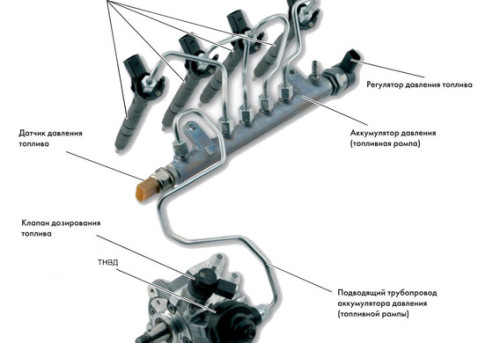

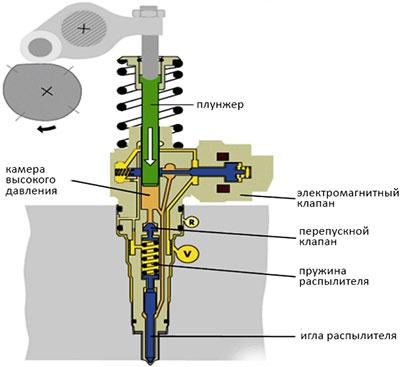

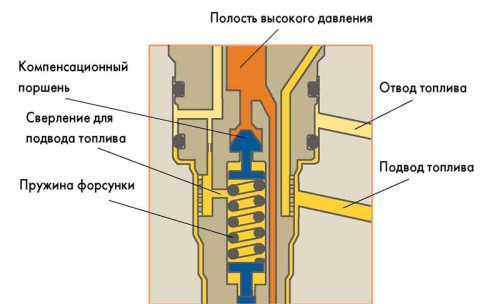

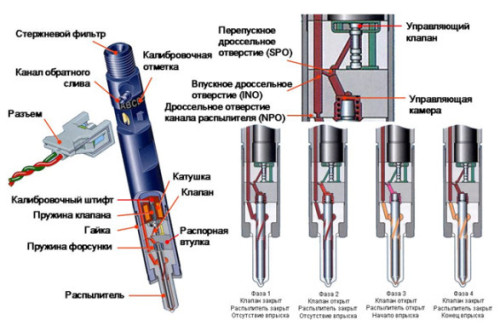

Di mesin diesel, termasuk yang dilengkapi dengan sistem injeksi "common rail", nozel elektrohidrolik digunakan. Desain perangkat ini mencakup katup elektromagnetik, ruang kontrol, serta saluran pembuangan dan asupan.

Prinsip pengoperasian peralatan tersebut didasarkan pada penggunaan tekanan bahan bakar selama injeksi, serta, setelah penghentiannya. Pada posisi awal, katup solenoid benar-benar tertutup dan de-energized, jarum perangkat ditekan ke pelana dengan tekanan pada piston bahan bakar di ruang kontrol. Injeksi bahan bakar dalam posisi ini tidak dilakukan. Perlu dicatat bahwa tekanan bahan bakar pada jarum, dalam situasi ini, lebih sedikit tekanan, yang diproduksi pada piston, sebagai hasil dari perbedaan di daerah kontak.

Setelah perintah ECU, solenoid valve dipicu dan throttle drain dibuka. Bahan bakar, yang terletak di ruang kontrol, sambil mengalir melalui throttle ke jalan raya. Asupan Choke adalah hambatan untuk leveling tekanan tercepat dalam garis saluran masuk dan ruang kontrol. Namun, secara bertahap ada penurunan tekanan pada piston, namun, tekanan bahan bakar yang dilakukan pada jarum tidak berubah, mengakibatkan peningkatan jarum dan injeksi bahan bakar.

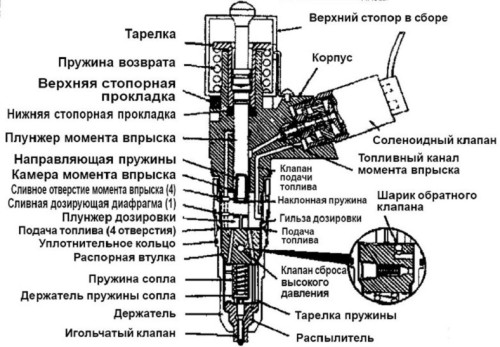

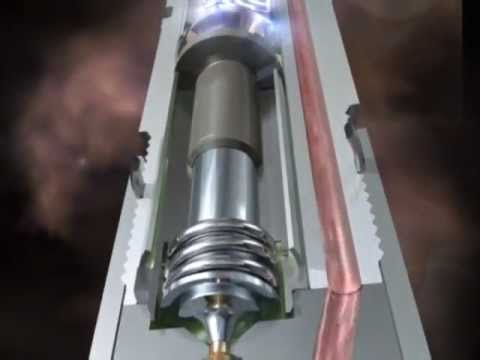

Piezoforun, perangkat

Desain piezoquomorming meliputi komponen-komponen tersebut:

- Saluran pasokan bahan bakar.

- Konektor nozzle listrik.

- Mikrofilter.

- Peternakan saluran.

- Piezeelement.

- Pusher piston.

- Piston katup.

- Katup pegas.

- Switching valve.

- Choke blok.

- Sprayer jarum musim semi.

- Pencuci tahan api.

- Jarum semprot.

Piezohoroforsunk, prinsip kerja

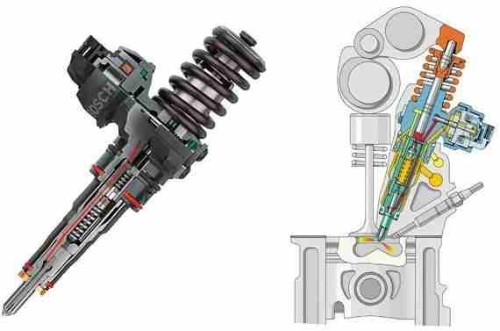

Pengoperasian katup kontrol nozzle didasarkan pada efek piezoelektrik terkenal yang digunakan, misalnya, dalam pemantik gas. Jari pria menekan tombol yang merusak komponen kerja dari dielektrik. Akibatnya, muatan yang digunakan untuk berkaitan dengan gas.

Dalam nozel piezoelektrik, t. N. Membalikkan efek piezoelektrik. Tegangan diumpankan ke dielektrik, yang berkontribusi pada deformasi material. Batang katup terhubung ke sana, yang mampu memanjat jika arus dimasukkan ke nozzle.

Piezohoroforsunk, martabat

- Nozel efisiensi tinggi.

- Mengurangi kebisingan dalam proses operasi motor.

- Kemampuan untuk mengubah tekanan injeksi.

- Tingkatkan kecepatan nozzle.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips berguna

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat menggerakkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar