Sistem rem dalam transportasi otomotif adalah tubuh yang paling penting, menghasilkan manifestasi minimal, bahkan minimal dari pekerjaannya yang salah, seperti peluit, mencicit, berderit dan lainnya, harus didiagnosis tepat waktu dan dihilangkan. Apa yang ditunjukkan oleh suara-suara ini dan bagaimana menghilangkan kerutan rem - baca lebih lanjut dalam artikel.

Isi

- Bantalan rem baru, alasan tangkapan layar

- Bantalan rem berderit setelah beberapa eksploitasi, mengapa mereka meremas

- Bantalan rem berderit karena getaran, alasan getaran, cara menghilangkan

- Pelumasan untuk rem, apa yang diperlukan pelumas dan cara menggunakannya

- Getaran dan bantalan rem berderit akibat perakitan berkualitas buruk, untuk memperhatikan saat menempel roda, di mana bahaya

- Disc rem hangat, konsekuensi dari pengoperasian mobil dengan sistem rem rusak

- Cara memeriksa cakram saat membeli, untuk memperhatikan, toleransi minimum untuk penyimpangan ketebalan disk di atas permukaan

- Tips pro: bagaimana cara menyelamatkan hidup ke pengemudi dan mobil

Bantalan rem baru, alasan tangkapan layar

Bantalan Skipping adalah hasil dari osilasi dalam proses gesekan pada rem cakram, yang merupakan resonator utama. Banyak faktor berbeda mempengaruhi proses ini. Untuk menghilangkan kebisingan, produsen pipa menggunakan piring anti-bertingkat khusus, tetapi mereka hanya dipasang pada "sepatu conveyor" - untuk tujuan menabung untuk dijual di pasar sekunder, mereka tidak dipasang.

Penyebab paling umum dari tangkapan layar adalah bantalan bahan berkualitas rendah. Setiap gesekan pad pad adalah komposisi polimer dari massa elemen. Produsen produk murah menyimpan dan menggunakan komposisi murah untuk membuat bantalan. Namun, tidak semua bantalan berderit buruk. Penyebab lain kemungkinan biola mereka tidak kompatibel dengan cakram rem. Oleh karena itu, perlu untuk membeli bantalan rem dan disk dari satu produsen.

Jika baru, hanya memasang bantalan rem, kemungkinan besar, mereka perlu waktu untuk bekerja. Tunggu sedikit, mungkin kebisingan yang tidak menyenangkan akan berlalu. Dan ini terjadi karena bagian atas pada blok adalah lapisan khusus dengan campuran yang menyebabkan suara yang berlawanan. Seiring waktu, ia harus menghilang (dengan abrasi penuh lapisan ini). Untuk menyingkirkan tangkapan layar dengan cepat, membuat pengereman yang intens.

Jika setelah proses pembalut tertentu terus bersiul dan berderit, Anda perlu menggantinya. Juga, derut dalam rem muncul sebagai hasil dari polusi mereka atau masuknya air. Dalam hal ini, perlu atau bersihkan bantalan, atau tunggu sebentar.

Bantalan rem berderit setelah beberapa eksploitasi, mengapa mereka meremas

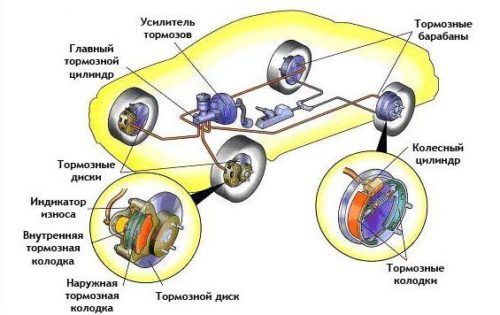

Setiap bantalan rem dilengkapi dengan indikator aus khusus (t. N. "piskuna"), yang terlihat seperti piring logam. Dengan keausan pad yang kuat, piring ini bersentuhan dengan cakram rem, itulah sebabnya berderit atau memekik. Ini menandakan penggantian Bantalan Rem yang mendesak.

Kerutan ini juga dapat memanifestasikan dirinya pada pembalut baru, yang terjadi sebagai akibat dari pengikat piring yang berkualitas rendah, itulah sebabnya ia sebelum waktunya dalam kontak dengan disk dan membuat suara yang tidak menyenangkan.

Selain itu, rem dapat berderit karena panas. Keributan ini tidak kuat, tetapi, bagaimanapun, ada. Dengan gerakan intensif di sekitar kota, bergantian overclocking dan pengereman, bahkan bantalan asli dapat sedikit berderit. Ini terjadi pada mobil, di mana cakram rem berventilasi tidak dipasang. Akibatnya, bantalan jarang dan dipublikasikan berderit, tetapi tidak signifikan dan dengan cepat dihilangkan ketika bantalan didinginkan.

Dalam proses mengganti bantalan, disarankan untuk melumasi kaliper panduan menggunakan pelumas khusus, karena itu adalah penyebab lain dari layar rem.

Terjadinya pelanggaran tidak diragukan lagi menyebabkan sensasi yang tidak menyenangkan, tetapi tidak mempengaruhi efisiensi pengereman. Jika Anda yakin bahwa keributan itu disebabkan oleh bantalan non-rem, periksa dan bersihkan sistem rem menggunakan cara khusus. Ada kemungkinan bahwa perakitan-pembongkaran, serta pelumas semua elemen bergerak akan membantu menyingkirkan layar.

Bantalan rem berderit karena getaran, alasan getaran, cara menghilangkan

Auto-osilasi menghasilkan bukan dari caliper rem atau disk, tetapi dari bantalan rem. Meskipun getaran itu membentuk semua elemen sistem rem, cakram dan kaliper tetap sangat keras, mengakibatkan penyerapan getaran, namun, pad dan kemudian tetap dalam gerakan amplitudo rendah, jadi driver dan mendengar pengerukan ini berderit dan mendengarkan mencicit. Dalam hal ini, Anda seharusnya tidak menyalahkan semua bantalan di semua, perlu untuk mendistribusikan seluruh sistem dan mendeteksi penyebab data osilasi. Sebenarnya, ada beberapa alasan seperti itu:

- Bantalan rem berkualitas rendah. Artinya, untuk tumpang tindih, lapisan mengambil campuran perekat yang buruk, lapisannya tidak homogen dalam komposisi dan sebagainya.

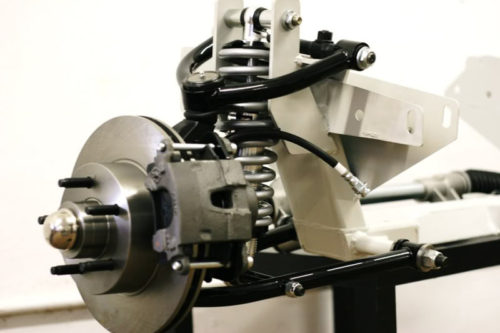

- Piston tidak sepenuhnya bergerak dengan benar di tambang caliper, sebagai akibat dari ambiguitas muncul di rem.

- Panduan caliper "kering", itulah sebabnya rem sedikit bengkok.

- Cakram rem hanya aus, sebagai akibat dari yang "bin" terbentuk sepanjang diameter disk luar.

Memecahkan masalah karena bantalan rem yang bergetar cukup sederhana:

- Kami menghapus debit pada disk menggunakan alurnya, tetapi hanya ketika ketebalan lapisan perbaikan memungkinkan untuk melakukan pekerjaan tersebut. Entah Anda harus mengganti cakram rem, karena ketika menginstal bahkan bantalan rem paling modis dan curam, tanaman dan derit tidak akan lulus dalam hal apa pun.

- Sebelum memasang pembalut baru, periksa caliper untuk adanya masalah, khususnya, periksa pengoperasian panduan dan piston. Panduan wajib melumasi dengan bahan khusus yang mengurangi gesekan.

- Selain itu, sebelum memasang bantalan rem baru, mereka harus mengoleskan ujungnya, serta dinding belakang lapisan dengan bantuan pasta anti-graded khusus. Secara alami, dilarang menyentuh permukaan sepatu.

Pelumasan untuk rem, apa yang diperlukan pelumas dan cara menggunakannya

Ada dua varietas pelumas rem - keramik dan tahan panas.

Pelumas keramik untuk kaliper dibedakan dengan mengandung partikel keramik mikroskopis dalam komposisi mereka, dengan efisiensi rem tinggi dalam kondisi yang berbeda dipastikan. Jika Anda dengan benar mengambil cairan rem, dimungkinkan untuk menghindari tidak hanya mengumpulkan dan membuat komponen caliper, tetapi juga untuk sepenuhnya menghilangkan penghancuran atau pusutan. Elemen akan paling aman terlindung dari efek berbahaya dari kotoran, debu dan kelembaban, serta semua jenis penurunan suhu.

Selain itu, pasta keramik dibedakan dengan ketahanan korosi yang tinggi dan tidak ramai dari deposito sepanjang masa pakai. Kombinasi sempurna pada kenyataannya dengan bahan pad apa pun. Pasta tidak diterapkan pada permukaan pad atau disk. Ini digunakan untuk melumasi elemen caliper rem cakram. Pilihan yang baik - pelumas keramik dari Liqui Moly, Permatax, Presto, Bardahl.

Penggunaan pasta tahan panas - pelat anti-slip, bantalan permukaan dan kurung. Pilihan yang sangat baik untuk sebagian besar model adalah pasta suhu tinggi untuk rem Liqui Moly dan Molykote CU-7439 plus. Jenis masa lalu ini telah membuktikan diri dengan tekanan dan suhu yang cukup tinggi, serta di tempat-tempat di mana karat diharapkan.

Ketika memilih pasta rem, perlu dicatat bahwa ia harus memenuhi persyaratan berikut:

- Resistensi terhadap berbagai dampak kimia.

- Tahan air.

- Resistensi termal yang baik.

- Kompatibilitas dengan plastik.

- Dalam kondisi suhu tinggi seharusnya tidak memanifestasikan dirinya. "Efek capple".

Getaran dan bantalan rem berderit akibat perakitan berkualitas buruk, untuk memperhatikan saat menempel roda, di mana bahaya

Karena jaket bahan gesekan atau perakitan yang salah, cacat dapat terjadi pada permukaan kerja disk, yang pada gilirannya, memerlukan deretan dan getaran. Untuk menyelesaikan masalah, Anda harus merendam permukaan disk atau melaksanakan langkah-langkah untuk memastikan kerataan cakram rem, di mana kami membongkar disk, dengan hati-hati membersihkan permukaan hub dari kontaminasi dan karat, dan kemudian menginstal ulang cakram rem. Pada bagian perifer dari disk, kami memeriksa beyon dengan mikrometer, yang ditetapkan pada basis magnetik. Jika nilai pemukulan melebihi 0,1 mm, coba instal ulang cakram rem, putuskan ke 180 atau 90 derajat relatif terhadap hub jika memungkinkan Anda untuk membuat konfigurasi lubang. Jika masalah tetap, ubah cakram rem.

Pemilik mobil yang jarang membuat kesalahan dengan bantalan instalasi independen, yang ditujukan untuk sisi tertentu, dan juga salah menempatkan perangkat anti-shift (lapisan), yang dapat menyebabkan tidak hanya berderit, tetapi juga masalah lain yang lebih serius. Karena itu, ketika memasang bantalan rem untuk ini harus memberikan perhatian khusus.

Disc rem hangat, konsekuensi dari pengoperasian mobil dengan sistem rem rusak

Secara alami, alasan utama cakram rem mengerem, yang dilakukan dengan berinteraksi dengan cakram rem dengan blok. Saat itulah disk dipanaskan. Perlu dicatat bahwa itu terjadi secara instan, tetapi tidak punya waktu untuk mendinginkan cakram rem, terutama jika kita berbicara tentang naik dalam mode perkotaan.

Penyebab kedua, tidak kalah penting dari pemanasan cakram - gaya mengemudi. Setiap pengemudi adalah individu dan, mungkin, tidak perlu menjelaskan bahwa dengan cara mengemudi yang agresif dalam kondisi perkotaan, yaitu, pengereman ekstrem dan akselerasi yang tajam, cakram rem akan dipanaskan terus menerus.

Dan akhirnya, ada kerusakan sistem rem. Lebih tepatnya bagian atau node individualnya. Pertimbangkan mereka secara lebih rinci:

- Bantalan rem non-kualitas (lapisan).

- Ketebalan bantalan rem dan ketebalan cakram rem kurang dari produsen dimensi minimum.

- Breeding Brake Disc.

- Penggunaan sistem mekanisme rem campuran. Rem belakang - drum, rem depan - disk. Ini adalah penyebab berat memanaskan cakram rem depan, karena beban utama saat pengereman jatuh pada gandar depan.

Bantalan dan disk pemanas intens permanen mampu memerlukan perubahan pada sifat-sifat material dari mana mereka dibuat. Pada saat yang sama, film ganas dibentuk antara cakram rem dan bantalan, yang memiliki kemampuan untuk secara signifikan mengurangi koefisien gesekan bantalan rem tentang permukaan disk. Akibatnya, efisiensi seluruh sistem rem berkurang secara signifikan. Dan bahkan jika pengemudi entah bagaimana beradaptasi dengan pengereman yang melemah, menyelesaikan masalah dengan fluida rem mendidih dalam hal apapun, itu tidak akan mungkin.

Ini mungkin memerlukan gangguan dari seluruh sistem pengereman. Dalam kebanyakan kasus, overheating yang kuat mengarah pada kerusakan caliper dan bantalan rem. Jika rem cakram hangat setelah mengganti bantalan, ada kemungkinan bahwa korosi di dekat gusi silinder rem adalah sumber subflink.

Cara memeriksa cakram saat membeli, untuk memperhatikan, toleransi minimum untuk penyimpangan ketebalan disk di atas permukaan

Saat membeli cakram rem bekas, pertama-tama, itu harus diperiksa menggunakan ketebalan dial di beberapa tempat. Mengapa? Ya, karena ada fenomena sebagai keausan disk yang tidak rata, yang terjadi karena berbagai alasan. Juga menarik inspeksi visual dari cakram rem untuk goresan dalam, warna dan kerusakan mekanis lainnya pada permukaan kerja disk.

Jika Anda membeli cakram rem baru, perhatikan biayanya. Seperti yang Anda ketahui, produk yang lebih baik, semakin mahal itu. Lebih baik memberikan preferensi untuk merek-merek terkenal, karena perusahaan besar mengurus reputasi mereka dan, sebagai aturan, menawarkan pelanggan hanya produk berkualitas tinggi.

Penerimaan ke penyimpangan ketebalan disk selama seluruh permukaan kerja adalah 0,0035 milimeter. Jika Anda menemukan non-keseragaman ketebalan cakram rem di luar toleransi, perlu untuk menggantinya, termasuk disc rem pasangan pada sumbu. Jika ketebalan disk telah berubah dalam toleransi, cobalah untuk menghilangkan masalah akuisisi ulang.

Namun, jika pengulangan tidak mengarah pada kesuksesan, disk dapat direndam menggunakan perangkat khusus. Tetapi, pada saat yang sama, pastikan bahwa ketebalan residu dari disk rem memungkinkan untuk melakukan ini, dan baterai bagian hub dari disk yang dipasang tidak melebihi 0,05 milimeter. Sekarang permukaan gesekan harus dihaluskan, memastikan kekasaran yang diperlukan - 3.2. Nah, disarankan untuk mengganti bantalan. Jika disk tidak dapat direndam, itu harus diubah.

Tips pro: bagaimana cara menyelamatkan hidup ke pengemudi dan mobil

Pertama-tama, perlu untuk mendiagnosis, memperbaiki, dan mengubah elemen-elemen sistem rem. Jangan lupa bahwa rem adalah salah satu simpul terpenting dari mobil dan bahkan masalah yang tidak signifikan pada pandangan pertama mampu mengarah pada konsekuensi fatal. Bungkus cakram dari deformasi buatan. Pada waktu yang panas dilarang untuk mencuci kendaraan segera setelah gerakan. Perlu untuk memberikan cakram rem untuk mendinginkan, jika tidak tindakan Anda sendiri, Anda akan mengancam bagian dari mekanisme rem.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips berguna

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat menggerakkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar