Sabuk mekanisme distribusi gas adalah atribut yang sangat diperlukan untuk sebagian besar kendaraan modern, termasuk untuk mobil Chevrolet Lacetti. Terlepas dari kesederhanaan luar biasa, ini adalah detail yang agak penting untuk mesin pembakaran internal. Memasang Kembali Timing Belt pada Chevrolet Lacetti - Acara ini cukup memakan waktu, tetapi benar-benar sederhana, jika Anda bertindak di bawah instruksi yang disediakan.

Isi

- Timing Belt, tugas apa yang dilakukan timing belt

- Timing Belt, saat ini bekerja dan dari bahan apa

- Seberapa sering mengubah timing belt

- Berapa banyak untuk mengubah timing belt, tanda apa yang dibicarakan tentang kebutuhan untuk mengganti timing belt

- Memecahkan sabuk waktu, yang memimpin rincian seperti itu

- Timing Belt, mengapa penggantian sabuk lebih baik untuk dilakukan dalam kit

- Alat, perlengkapan, bahan habis pakai

- Teknik Keselamatan

- Mengganti timing belt chevrolet lacetti, langkah demi langkah bekerja

- Tips Profi, Cara Memeriksa Ketegangan Sabuk Waktu

Timing Belt, tugas apa yang dilakukan timing belt

Tugasnya adalah bahwa camshaft diputar pada kecepatan, persis setengah dari pergantian poros engkol. Setengah abad yang lalu, drive rantai GRM digunakan dalam industri otomotif, dan semua upaya untuk mengadaptasi sabuk untuk ini adalah kesalahpahaman. Banyak waktu berlalu sebelum ikat pinggang mulai mendominasi. Tetapi ia memiliki beberapa keunggulan signifikan - menyederhanakan desain, kebisingan rendah dan penurunan massa unit daya.

Saat ini, produsen lebih suka memasang drive sabuk di mobil mereka. Tetapi tidak mungkin untuk mengatakan dengan tegas bahwa rantai lebih buruk daripada sabuk. Rantai drive juga memiliki keunggulan - daya tahan, berkorelasi dengan durasi motor itu sendiri. Oleh karena itu, bahkan di zaman kita, beberapa perusahaan manufaktur menghentikan pilihan mereka pada mekanisme rantai. Selain itu, motor seperti itu biasanya dilengkapi dengan tensioner otomatis. Kehidupan layanan sabuk biasa sangat jarang melebihi 60 ribu kilometer, dan kesederhanaan desain mensyaratkan kebutuhan akan layanan permanen - pull-up, penggantian, kontrol atas status sabuk.

Timing Belt, saat ini bekerja dan dari bahan apa

Agar sabuk waktu untuk bekerja dengan andal, kondisi berikut harus diamati - keadaan optimal dari katrol dan rol di mana sabuk dipindahkan, ketegangan sabuk yang benar, perlindungan absolut terhadap minyak dan kotoran. Desain ikat pinggang cukup sederhana dan sesuatu menyerupai ban mobil.

Oleh karena itu, sebagian besar perusahaan yang berspesialisasi dalam produksi ban juga menghasilkan ikat pinggang. Dasar dari timing belt - kabel - pleksus benang tahan lama dari fiberglass. Kabel di dalam adalah gigi dari bahan tahan aus (sebagai aturan, nilon), dan di luarnya melindungi lapisan karet, ketebalannya sekitar lima milimeter. Desain ikat pinggang cukup beragam. Mungkin berbeda dalam lebar ikat pinggang, jumlah dan langkah gigi, serta profil mereka (ada sekitar dua puluh jenis profil gigi).

Seberapa sering mengubah timing belt

Penggantian sabuk waktu pada Chevrolet Lacetti, sesuai dengan peraturan pemeliharaan, perlu dilakukan setiap 60.000 kilometer jarak tempuh. Namun, sebagian besar spesialis merekomendasikan untuk mengurangi perubahan pada periode penggantian karena kondisi operasi yang kompleks. Adapun verifikasi keadaan ikat pinggang, kemudian pada mobil Chevrolet Lacetta harus dilakukan setiap 30 ribu kilometer.

Berapa banyak untuk mengubah timing belt, tanda apa yang dibicarakan tentang kebutuhan untuk mengganti timing belt

- Memakai bahan. Timing belt dapat keluar dengan cara yang sama seperti, misalnya, ban. Jika bahan sabuk dikenakan, itu dapat terjadi untuk membukanya atau tergelincir. Apalagi ini sering terjadi pada beban besar pada motor motor. Misalnya, ketika melacak trailer atau trailer, serta dalam cuaca basah.

- Sabuk abrasi. Ini terjadi, sebagai aturan, dengan penyimpangan dari katrol dan roller tensioner dari posisi belakang, serta ketika kerusakan bantalan dan peningkatan suhu. Dalam hal inspeksi, Anda dapat melihat keausan gigi sabuk - basis tisu (serat kain dilatasi dan tekstur yang tidak rata).

- Detasemen atau retakan. Fitur keberanian ini jelas. Perlu untuk menjelajahi permukaan belakang dan depan sabuk. Kehadiran retakan, terutama jika ada banyak dari mereka, menunjukkan aus yang kuat.

- Pengerasan permukaan yang berlawanan dari sabuk bergigi adalah permukaan yang berlawanan dari sabuk itu keras, tidak elastis dan berkilauan. Dalam hal ini, sabuk menjadi tidak dapat tenggelam, sebagai akibatnya tidak lagi memberikan kontak yang diinginkan dengan katrol.

- Pemanjangan. Pakaian material mampu memimpin perpanjangan sabuk yang kuat, sebagai akibat dari mana roller ketegangan bergerak melampaui batas-batas yang diizinkan. Ini mengurangi kekakuan dan ketegangan sabuk total, dan, akibatnya, kinerja keseluruhan mekanisme.

- Penyimpangan dari posisi yang ditunjuk. Fitur ini menunjukkan bahwa elemen internal roller tensioning cukup dekat dengan kerusakan. Jika roller gagal, itu akan menyebabkan peningkatan kebisingan, suhu dan getaran.

Memecahkan sabuk waktu, yang memimpin rincian seperti itu

Kecelakaan timing belt dapat mensyaratkan massa konsekuensi yang tidak menyenangkan yang berbeda, mulai dari kebutuhan untuk menggantikan timing belt dan mengembalikan mekanisme distribusi gas dan perombakan motor.

Situasi yang paling sulit adalah ketika katup ditekuk sebagai akibat dari istirahat sabuk. Ini hanya dijelaskan. Kesenjangan dapat terjadi pada periode ketika katup turun ke injeksi bahan bakar atau pelepasan gas. Pada saat yang sama, pergerakan piston di silinder masih berlanjut dan mereka dapat memukul mereka dari seluruh kekuatan. Dalam hal ini, "rapat" dapat berakhir dengan sangat buruk.

Perkirakan tingkat kerusakan dapat dievaluasi hanya setelah membongkar kepala motor dan memperkirakan keadaan sistem piston dan katup. Perlu dicatat bahwa cacat katup tidak dapat segera melihat - untuk diagnostik memerlukan peralatan khusus.

Timing Belt, mengapa penggantian sabuk lebih baik untuk dilakukan dalam kit

Untuk menghindari masalah di masa depan, penggantian timing belt diinginkan untuk menghasilkan bersama dengan pompa dan rol. Ini bukan tindakan wajib, namun, jika ada dana tambahan, sebaiknya jangan malas karena akan mempengaruhi efisiensi timing belt baru.

Selain itu, untuk memenuhi penggantian, Anda harus sepenuhnya membongkar semua komponen peralatan ini, termasuk pompa dengan rol. Dengan demikian, penggantian habis pakai biaya prosedur ini tidak akan meningkat banyak, dan tidak akan membutuhkan banyak waktu, tetapi akan meningkatkan masa pakai agregat yang diganti.

Alat, perlengkapan, bahan habis pakai

- Kepala "10", "12", "14", "17", "32".

- Penekanan yang dapat disesuaikan.

- Segi enam pada "5".

- Kunci untuk "41".

- Passatia.

Teknik Keselamatan

Tidak mungkin bekerja di bawah kendaraan jika diposting hanya pada jack. Sebagai asuransi pada wajib, gunakan stasiun kondisi pabrik. Dilarang menggantung mobil pada dua atau lebih jack. Untuk melindungi tangan Anda dari memar dan memotong dengan operasi "kekuatan", Anda harus bekerja di sarung tangan.

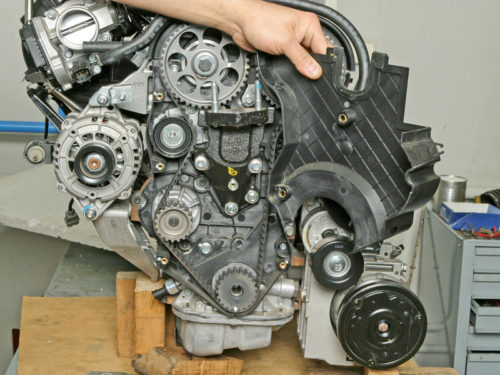

Mengganti timing belt chevrolet lacetti, langkah demi langkah bekerja

- Buka kap dan bongkar lapisan dekoratif dengan motor, yang Anda butuhkan untuk membuka empat kacang.

- Untuk kenyamanan, bongkar perumahan filter udara. Untuk melakukan ini, dengan penutup filter udara, kami membuka empat sekrup, serta lapisan nozzle udara. Kami membongkar tutup dan filter udara. Untuk menghapus perumahan filter itu sendiri, buka dua baut lagi.

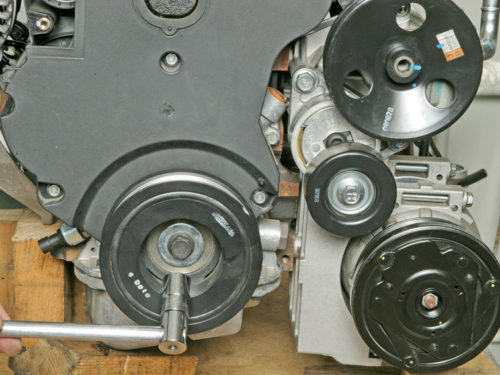

- Sekarang hapus sabuk drive - tarik rol drive menggunakan tombol ke "17" dan bongkar sabuk dari katrol. Selanjutnya, Anda harus membuka dua baut dan lepaskan penutup atas penutup timing.

- Kami membuat penghapusan roda kanan depan dan anther lateral motor, yang melekat pada tiga piston dan dua baut.

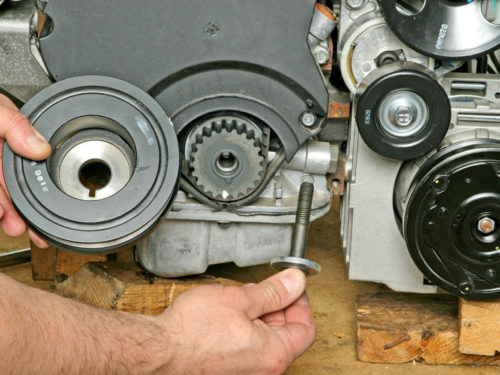

- Kami membuka pulley crankshaft, yang Anda perbaiki roda gila menggunakan obeng berlubang besar melalui jendela tampilan. Kemudian, dengan tukang las dan kepala pada "17" kami membuka dan membongkar katrol engkol.

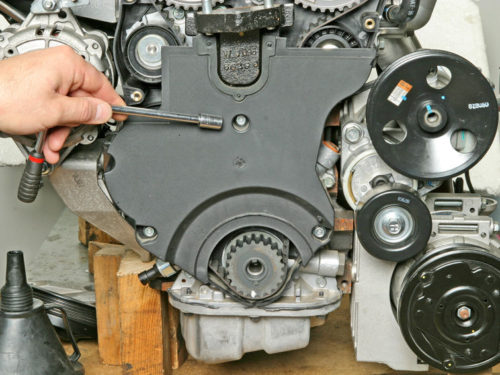

- Anda juga harus menghapus penutup bawah dari timing belt, yang dilampirkan oleh tiga cogs.

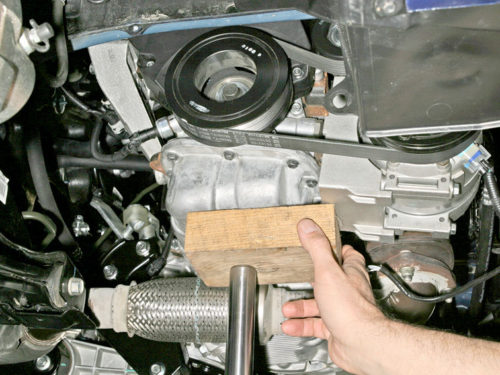

- Langkah selanjutnya adalah menghapus dukungan mesin, untuk apa yang Anda butuhkan untuk menginstal jack tambahan untuk unit daya di bawah palet. Kemudian kami membuka 3 kacang dan 1 baut menggunakan kunci untuk "14" dan membongkar dukungan OBS.

- Kami membuka empat baut di sekeliling braket support dan menghapus braket.

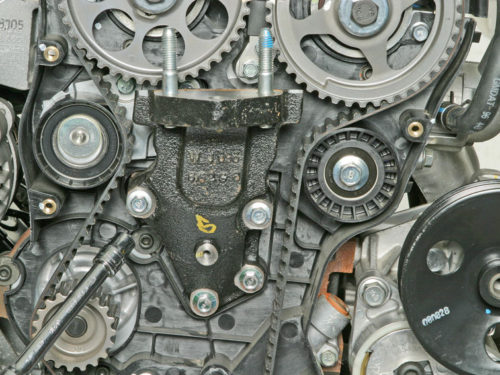

- Selanjutnya, pada semua katrol, kami menetapkan tag waktu. Di katrol crankshaft itu akan berada di bawah.

- Untuk kenyamanan rotasi crankshaft, kencangkan kembali pulley baut.

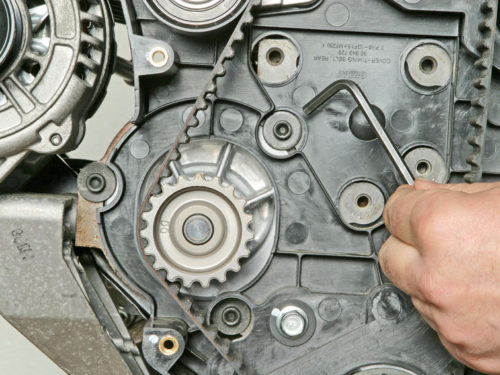

- Sekarang lanjutkan untuk mengganti timing belt. Menggunakan kunci untuk "14", kami membuka roller parasit, yang terletak di sebelah kanan dan membongkar sabuk, setelah itu kami membuka tensioner roller, yang terpasang oleh tiga baut.

- Sebelum memasang ikat pinggang, periksa tag, karena setelah melepas mereka bisa dirobohkan.

- Ketika tetap hanya mengenakan ikat pinggang pada pompa, pindahkan roller tensioner, setelah itu sampai ke ujung ikat pinggang dan periksa instalasi label.

- Selanjutnya, gulir crankshaft searah jarum jam pada satu atau dua putaran dan periksa label lagi.

Tips Profi, Cara Memeriksa Ketegangan Sabuk Waktu

Untuk memeriksa ketegangan sabuk waktu, putar crankshaft dua hingga tiga kali searah jarum jam dan lihat gigi roller tensioner. Perlu bahwa mereka berdiri di seberang satu sama lain - ditambah-minus beberapa milimeter. Jika bacaan berbeda, Anda harus menyesuaikan ketegangan sabuk menggunakan pompa.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips bermanfaat

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips berguna

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat memindahkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar