Setiap pemilik mobil tahu apa itu antibeku dan mengapa ia membutuhkan mobil. Tanpa cairan ini, karya kendaraan apa pun, termasuk Chevrolet Lacetti, tidak mungkin. Cara menguras cairan pendingin dari model mobil ini dan tuangkan yang baru setelah mencuci sistem - baca lebih lanjut dalam artikel.

Isi

- Antibeku, mengapa dibutuhkan tempat dituangkan

- Pendingin atau antibeku, seberapa sering perlu untuk mengubah antibeku

- Anggur apa yang harus dipilih, kriteria untuk memilih cairan pendingin

- Mengapa tidak bisa dicampur dengan bekas antibeku dan larutan antibeku baru

- Cara Memeriksa Antibeku

- Alat, perlengkapan, bahan habis pakai

- Teknik Keselamatan

- Cara Merge Antibeku

- Cara Bilas Sistem

- Cara mengisi instruksi antibeku, langkah demi langkah

- Saran pro bagaimana membuang antibeku

Antibeku, mengapa dibutuhkan tempat dituangkan

Cairan untuk pendinginan motor (itu juga disebut "antibeku", "refrigeran" dan "radiator cair") diperlukan untuk mobil untuk melakukan sejumlah fungsi. Pendinginan mesin adalah salah satu tugas refrigeran primer, tetapi juga melakukan fungsi lain, yaitu:

- Pendinginan cairan hidrolik hadir dalam transmisi otomatis.

- Memuat pompa unit daya yang melanjutkannya.

- Menghangatkan pengemudi di musim dingin, melewati inti pemanas.

Selain itu, komposisi antibeku yang diproduksi hingga saat ini mencakup zat khusus yang menangkal penampilan skala dan mencegah munculnya deposito. Namun, perlu dicatat bahwa zat-zat kimia tersebut memiliki masa berlaku yang relatif singkat. Antibeku dituangkan ke dalam tangki ekspansi khusus, yang ada di kompartemen mesin.

Pendingin atau antibeku, seberapa sering perlu untuk mengubah antibeku

Produsen merekomendasikan untuk mengubah antibeku setiap 40-50 ribu kilometer jarak tempuh, yang akan sepenuhnya menghilangkan mesin overheating. Spesialis yang bekerja untuk seratus disarankan untuk mengubah refrigeran setidaknya setahun sekali, jika tidak, karat mungkin timbul.

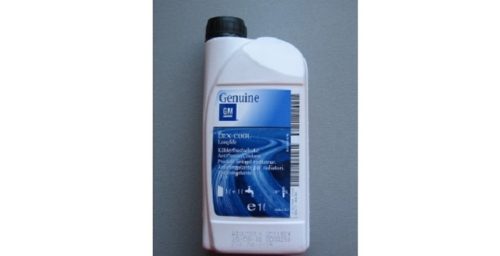

Anggur apa yang harus dipilih, kriteria untuk memilih cairan pendingin

Pilihan cairan pendingin harus didekati dengan sangat bertanggung jawab. Pertama, baca manual pemeliharaan mobil, karena antibeku yang berbeda dituangkan ke berbagai jenis mesin. Ada sejumlah kriteria pemilihan refrigeran utama:

- Suhu kristalisasi rendah.

- Tahan panas.

- Kapasitas panas yang cukup tinggi.

Selain kriteria dasar yang disebutkan di atas, pendingin tidak boleh mengekspos korosi logam, yang dicapai dengan bantuan inhibitor aditif khusus, dan tidak boleh membentuk busa selama pengoperasian unit daya.

Mengapa tidak bisa dicampur dengan bekas antibeku dan larutan antibeku baru

Dalam cairan pendingin yang diproduksi saat ini adalah zat yang mencegah munculnya karat. Saat mencampurkan antibeku lama dan baru, karakteristik anti-korosi mereka berkurang secara signifikan. Durasi aksi cairan anti-korosi secara signifikan tergantung pada berbagai komponen anti korosi di dalamnya.

Sementara mereka terkandung dalam antibeku dalam jumlah yang diperlukan, tidak perlu penggantian. Namun, dengan penurunan jumlahnya, probabilitas apa yang disebut muncul. Korosi elektrolit pada motor dan radiator mobil. Akibatnya, penggantian refrigeran lebih baik untuk tidak menunda.

Cara Memeriksa Antibeku

Refrigeran dituangkan secara eksklusif dalam sistem pra-anyaman. Untuk memeriksa antibeku, strip khusus untuk pengujian digunakan. Selain itu, perlu dicatat bahwa beberapa variasi antibeku dijual dalam bentuk terkonsentrasi. Sebelum menuangkan refrigeran seperti itu, itu harus dilarutkan menggunakan air suling.

Alat, perlengkapan, bahan habis pakai

- Satu set kunci.

- Set Obeng.

- Selang.

- Kapasitas untuk 8-10 liter.

- Antibeku Baru.

- Alat khusus untuk sistem flushing.

Teknik Keselamatan

Pengurasan antibeku harus dilakukan di tempat yang tidak tersedia untuk anak kecil, karena pendinginnya sangat beracun. Sangat dilarang untuk mengalirkannya di reservoir. Mengganti refrigeran dilakukan pada mesin yang dingin.

Cara Merge Antibeku

- Anda dapat mengeringkan refrigeran dengan menggunakan crane drain, yang terletak di radiator, yang kami buka katup pembuangan untuk beberapa revolusi.

- Untuk mencegah antibus berlari di bak mesin dan bagian tubuh lainnya, selang harus ditarik di derek.

- Di bawah drain crane, kami menggantikan wadah untuk pembuangan refrigeran.

- Kami membuka crane dan menguras antibeku.

- Untuk mempercepat saluran pembuangan, Anda dapat melepas tutupnya dari tangki.

Cara Bilas Sistem

- Ketika seluruh tangkai refrigeran, kami membilaskan sistem menggunakan agen pembilasan khusus yang perlu dituangkan ke dalam tangki ekspansi.

- Kemudian kami membawa unit daya dan membiarkannya bekerja sebentar sampai suhunya naik ke pekerja.

- Dalam wajib, kami menghidupkan seluruh kekuatan ke kompor sehingga semua gelembung udara keluar dari sistem.

- Ketika motor menghangatkan, harus tenggelam dan menunggu sampai dingin.

- Selanjutnya, tiriskan cairan cuci.

Cara mengisi instruksi antibeku, langkah demi langkah

- Buka tangki ekspansi dan tuangkan antibeku dengan lembut di sana.

- Putar steker.

- Kami yakin bahwa di mana saja tidak ada kebocoran fluida.

- Kami menghidupkan motor dan menunggu sampai menghangat hingga suhu operasi.

- Selanjutnya, matikan unit daya dan tunggu sebentar sampai dingin.

- Periksa level cairan dan isi, jika perlu.

Saran pro bagaimana membuang antibeku

Pendingin yang dihabiskan tidak dapat ditarik ke tanah terbuka ke saluran pembuangan. Simpan antibeku fusi seharusnya hanya wadah tertutup rapat. Hingga saat ini, ada perusahaan khusus yang terlibat dalam pembuangan refrigeran. Pilihan terbaik akan terpaksa membantu mereka.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips bermanfaat

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat memindahkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Kita masih harus tahu apa yang harus diunggah yaitu Apa antibeku berkualitas tinggi. Misalnya, untuk Lacetti saya, saya bahan bakar Coolstream Premium, selama 4 tahun tidak ada masalah. Ketika saya membuat pilihan bagi saya, kriteria utama adalah toleransi resmi dari pembuat mobil (Chevrolet), + adalah antibeku organik murni.

Dan saya pribadi, tanpa perbedaan, apa yang harus dituangkan, saya menggunakan mobil 10 tahun 20000km mencampur semua produsen G12 dan tidak ada yang kami dan tidak adur dengan antibeku terjadi 5 tahun, kemudian setelah 5 tahun hanya gelap dan pergi di bawah penggantian. Dan semua rekomendasi dari pabrik omong kosong

Mares.