Catu daya kendaraan memelihara transmisi torsi ke transmisi, yang sesuai dengan berbagai Rev .. Gearbox juga menghasilkan perubahan torsi ke yang lebih kecil atau paling sisi dengan mengubah rasio roda gigi gear. Namun, untuk melibatkan gigi yang diperlukan, gearbox harus terputus dari pembangkit listrik, dengan kata lain, sehingga keterlibatan terjadi, poros PPC primer seharusnya tidak mengambil rotasi dari roda gila. Untuk pemutusan jangka pendek CP dari pembangkit listrik, kopling disediakan dalam desain otomatis. Tugas komponen ini adalah untuk sementara memutus gearbox dari unit daya untuk memasukkan gigi gigi tertentu saat gear shift. Selain itu, kopling membuat transmisi rotasi selama awal gerakan dari tempat. Tindakan adhesi didasarkan pada kekuatan gesekan antara bahan yang berbeda dalam struktur. Di dalam kendaraan, gesekan digunakan antara komponen logam - disk tekanan, roda gila dan gesekan, yang dibuat dalam bentuk lapisan dan terletak di disk slave.

Isi

- Adhesi Mobil, Perangkat dan Prinsip

- Kerusakan kopling mobil, fitur kemungkinan malfungsi

- Mengganti kopling, dalam kasus apa yang diperlukan untuk mengganti kopling

- Keselamatan dan tempat untuk bekerja

- Alat, perlengkapan, bahan habis pakai

- Cara menghapus gearbox untuk sampai ke instruksi kopling, langkah demi langkah

- Cara menghapus dan meletakkan kopling, langkah demi langkah petunjuk

- Tips profi tentang penggunaan suntingan yang sudah disiapkan sehingga tidak ada masalah dengan instalasi kucing di tempatnya

Adhesi Mobil, Perangkat dan Prinsip

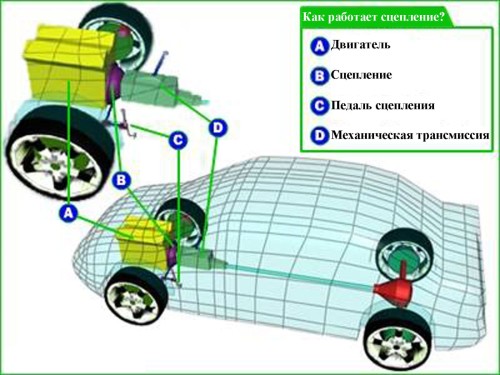

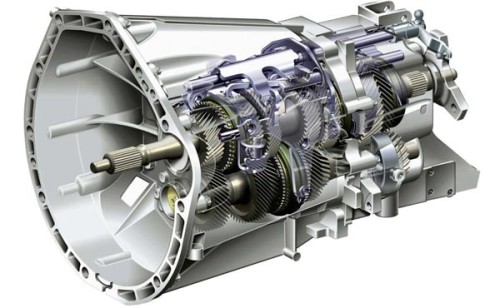

Kopling otomotif terdiri dari drive dan dua drive - memimpin dan menjadi budak.

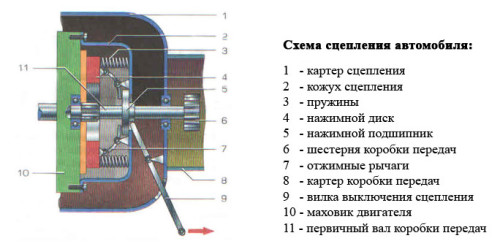

Desain disk drive termasuk casing disk - keranjang, yang dengannya melekat pada roda gila. Di dalam casing adalah disk tekanan, yang menekan permukaannya ke disk slave, atau lebih tepatnya, ke lapisan gesekannya. Disk ini mampu bergerak di dalam keranjang. Disk drive juga terdiri dari pegas yang ditekan ke bantalan gesekan dari disk tekanan.

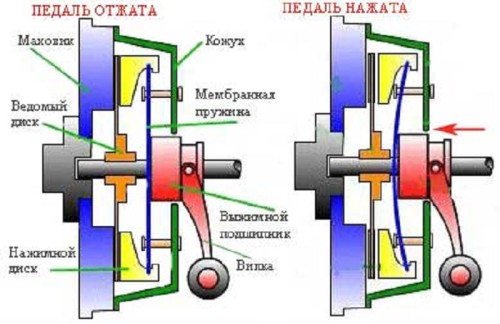

Untuk memindahkan disk tekanan di dalam keranjang dan, karenanya, hapus penekannya ke disk slave, perlu untuk mengatasi kekuatan pegas. Dalam pengiriman TCS untuk ini, tuas berlaku. Mobil memiliki desain yang sedikit berbeda - pegas diafragma digunakan di sini, yang dibuat dalam bentuk kerucut cut-off dengan bagian atas cut-off. Musim semi tepi luar melekat pada disk tekanan. Kerucut itu sendiri menonjol sedikit dari casing. Kerucut ini lebih dekat ke pusat, kelopak yang melakukan peran tuas. Saat mengindas kelopak ini ke dalam, kerucut mampu menekuk dan menghapus disk tekanan di dalam keranjang.

Disk slave adalah logam, dari dua sisi di mana lapisan gesekan diguncang atau dilem. Di tengahnya ada lengan angkatan laut, yang terhubung ke bagian baja dengan alat peredam dan mesin cuci gesekan. Dengan hub slotted ini, ditanam pada poros utama pos pemeriksaan.

Saat menghubungkan mesin ke CPP, ketika disk slave ditekan oleh tekanan ke roda gila, pegas dikompresi, dengan demikian memastikan kelancaran inklusi.

Dibutuhkan pegas gesekan dalam desain disk untuk membersihkan osilasi memutar.

Drive kopling adalah bantalan es, colokan penutup kopling dan sistem tuas.

Semuanya berfungsi sebagai berikut. Jika kopling pedal dirilis, pegas diafragma, karena tidak ada yang memengaruhinya, menekan ke roda gila dengan tekanan disk yang digerakkan - rotasi ditransmisikan secara terus menerus.

Ketika pengemudi meremas pedal, gaya ditransmisikan ke steker menggunakan sistem tuas. Steker menekan pada bantalan es, yang terletak di poros utama KP. Bantalan bergerak di sepanjang poros dan klik pada laba-laba dari jenis diafragma, yang masuk jauh ke dalam keranjang dan menekan pada disk tekanan, yang pada gilirannya, bergerak, berhenti menekan disk slave, sebagai akibat dari mana transmisi Berhenti rotasi, yaitu, motor terputus dari pos pemeriksaan.

Kerusakan kopling mobil, fitur kemungkinan malfungsi

Masalah kopling yang paling umum:

- "Slotchka". Masalah ini terjadi jika cengkeraman salah disesuaikan - langkah bebas sebenarnya tidak ada, dan tekanan bantalan pada pegas diafragma. Dalam hal ini, bahkan jika pedal benar-benar dirilis, kopling semuanya tetap sedikit diperas, yang disertai dengan cakram. Jika masalah ini tidak dihilangkan, sebagai akibat dari suhu tinggi, bagian logam dari disk slave dapat bengkak, memakai lapisan cepat dan, mungkin, kehancuran mereka, mereka akan naik, dan retakan kecil terbentuk pada roda gila .

- Kopling "leads". Masalah ini juga terbentuk dengan penyesuaian yang salah. Namun, itu jatuh ke terlalu banyak langkah bebas. Kopling dalam hal ini tidak mendorong disk tekanan sepenuhnya, rotasi ditransmisikan bahkan jika meremas pedal sebanyak mungkin. Ini secara negatif mempengaruhi disk yang mungkin bersumpah, retak atau bahkan menarik CPP.

- Batang saat memulai. Dimungkinkan untuk menghancurkan bantalan disk, bermunculan mata air peredam dari kursi. Selain itu, dimungkinkan untuk menghubungkan hub disk saat bergerak dan memisahkan kelopak mata air membran, sebagai akibat dari mana disk tekanan bergerak dengan distorsi.

- Peningkatan kebisingan dalam proses kerja menunjukkan kegagalan bantalan rilis.

Mengganti kopling, dalam kasus apa yang diperlukan untuk mengganti kopling

Kebutuhan akan membongkar dan mengganti kopling, sebagai aturan, terjadi ketika masalah yang dijelaskan di atas muncul - kebisingan kuat saat bekerja kopling, langkah bebas besar atau ketidakhadirannya, tropping brengsek.

Keselamatan dan tempat untuk bekerja

Pada mobil Vaz untuk sampai ke kopling, Anda harus membongkar gearbox. Dan karena dia dihapus, Anda akan membutuhkan lubang observasi. Dalam Wajib, ikuti teknik keamanan, untuk menghindari masalah.

Alat, perlengkapan, bahan habis pakai

- Komponen kopling baru.

- Edit yang dapat dibuat dari poros drive lama.

- Set kunci.

Cara menghapus gearbox untuk sampai ke instruksi kopling, langkah demi langkah

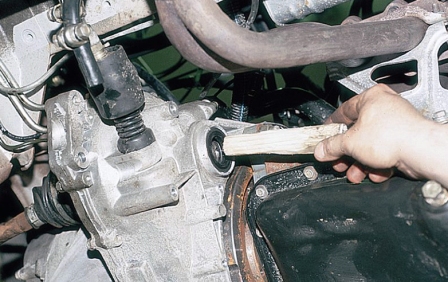

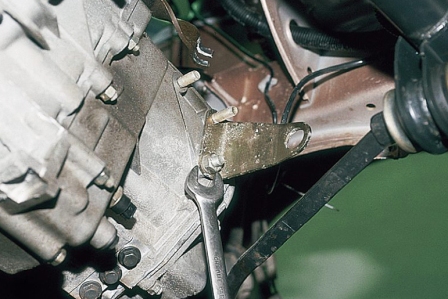

Kami melanjutkan pembongkaran. Dari Carter, lepaskan kabel kopling, dan dari pos pemeriksaan - Traction Lever Gearbox. Selanjutnya, lepaskan starter, dan dengan CP menggabungkan minyak.

Lalu kami membuka dan menghapus poros drive. Sehingga roda gigi tidak bergeser ke dalam kotak, setidaknya di satu sisi perlu untuk memasukkan tuis tua.

Selanjutnya, buka semua crankcase mount ke motor. Agar PPC untuk menghapus, di sisi kiri mobil menghapus tuas suspensi yang lebih rendah.

Motor harus ditandatangani, karena Anda harus membuka dukungan kiri dan belakang. Kemudian memelihara gearbox, antara instalasi daya dan crankcase clutch, kami mengendarai obeng dan menghapus crutl crankcase dengan tumpahan.

Cara menghapus dan meletakkan kopling, langkah demi langkah petunjuk

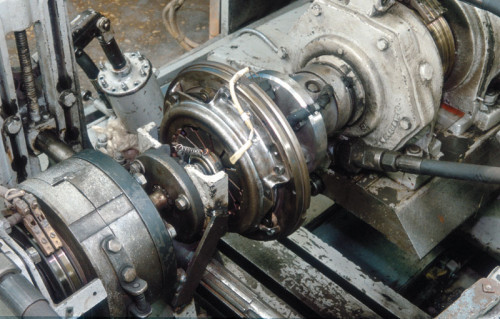

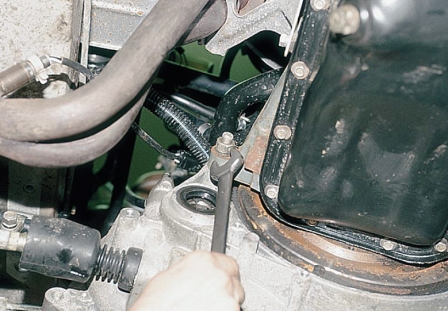

Sebelum melepas keranjang memasukkan pengeditan yang telah ditentukan ke tempat poros utama KP.

Selanjutnya, buka baut pengikat dari keranjang kopling, setelah itu kami menghapus drive disk dengan mobil.

Sekarang lepaskan disk slave.

Kemudian kami secara visual mengevaluasi elemen kopling. Jika Anda menemukan setidaknya kerusakan kecil pada bagian adhesi, perlu untuk mengganti kopling TC.

Menginstal pembuatan kopling baru dalam urutan terbalik.

Tips profi tentang penggunaan suntingan yang sudah disiapkan sehingga tidak ada masalah dengan instalasi kucing di tempatnya

Jangan lupa menggunakan pengeditan. Tanpa itu, tidak mungkin untuk melakukan pusat untuk lokasi disk slave, dan di masa depan Anda mungkin memiliki masalah dengan pengaturan gearbox di tempat.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips bermanfaat

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat memindahkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar