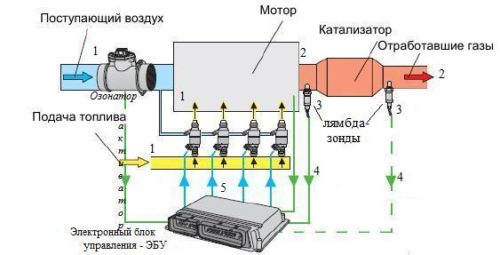

Sistem pembuangan mobil dan probe lambda saling berhubungan erat. Harus dipahami bahwa keberadaan perangkat ini di dalam mobil tidak disengaja, pada prinsipnya, seperti sensor teknologi tinggi lainnya. Ya, itu adalah sensor, karena probe lambda masih disebut sensor oksigen yang berbeda (o 2-sensor), yang sepenuhnya dibenarkan. Kemudahan servis sensor ini sangat mempengaruhi pengoperasian sistem bahan bakar mobil secara keseluruhan, sehingga pemeriksaan probe lambda harus dilakukan setidaknya setiap sepuluh ribu kilometer jarak tempuh. Banyak pengendara percaya bahwa sekitar 2-sensor dan katalis saling terkait erat dalam pekerjaan, tetapi ini bukan pendapat yang tepat. Sebagai aturan, katalis dipasang setelah probe lambda dan tidak mempengaruhi operasinya. Namun, kehadiran sensor oksigen secara signifikan memperluas pengoperasian katalis, karena kehidupan layanannya langsung tergantung pada kualitas campuran yang mudah terbakar. Tentang ini lebih lanjut dalam artikel.

Isi

- Perangkat Probe Lambda

- Bekerja lambda probe.

- Probe sensor oksigen lambda, karena mempengaruhi komposisi campuran bahan bakar

- Probe lambda, jenis perangkat

- Sensor penyelidikan oksigen lambda, menyebabkan kerusakan dan yang mengancam mobil selama operasi

- Lambda menyelidiki, memeriksa kesehatan sensor dengan cara visual, sebab dan konsekuensi: kotoran, jelaga dan keserakahan pada sensor

- Sensor Oksigen Lambda Probe, memeriksa layanan dengan peralatan, operasi terperinci saat memeriksa voltmeter untuk campuran bahan bakar yang habis

- Periksa osiloskop, dekripsi grafik membaca

- Tips Pro: Cara Memeriksa dengan Benar

- Kesimpulan dan rekomendasi

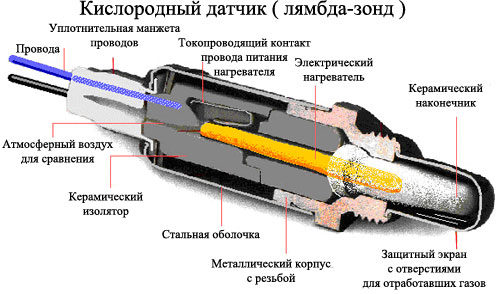

Perangkat Probe Lambda

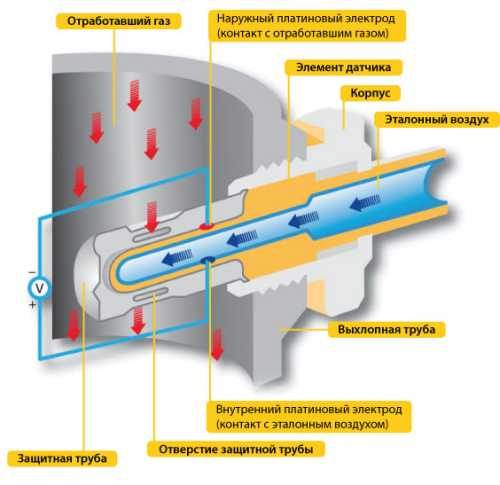

Dalam desain sensor oksigen termasuk komponen seperti itu:

- Perisai pelindung dengan lubang khusus untuk pelepasan gas.

- Spiral terletak di reservoir khusus.

- Ujung keramik.

- Kontak konduktif.

- Perumahan pelindung di mana lubang dibor, yang menyediakan ventilasi.

- Kabel dengan manset khusus untuk disegel.

- Segel (cincin).

- Isolator keramik.

- Kasing logam dengan ukiran cincang.

Keunikan sensor ini - bahan tahan panas yang eksklusif digunakan untuk produksinya, karena mereka harus berfungsi pada suhu tinggi.

Bekerja lambda probe.

Dasar dari probe lambda didasarkan pada fenomena efek electroplating. Arti dari fenomena ini didasarkan pada kenyataan bahwa, ketika membandingkan gas buang dan udara atmosfer murni pada elemen sensor, terjadi tegangan. Ini terjadi dengan bantuan proses fisik yang kompleks, yang tidak masuk akal untuk mempertimbangkan di sini.

Arus dari sensor oksigen memasuki komputer, yang mengubah komposisi campuran yang mudah terbakar tergantung pada indikator tegangan. Probe lambda hanya berfungsi pada suhu tinggi (300-400 derajat Celcius), karena hanya dalam kondisi seperti itu, arus listrik diproduksi dalam sensor dan elemen galvanik bekerja.

Pada motor dingin, campuran yang mudah terbakar terbentuk pada kesaksian sensor lain, dan probe lambda memulai pekerjaannya secara otomatis saat mengendarai motor. Beberapa transportasi dipasang pada 2-sensor dengan dipanaskan bawaan, yang masih pada tahap awal pengoperasian motor memastikan pasokan terakhir campuran yang mudah terbakar berkualitas tinggi.

Jika standar O 2-sensor mengoperasikan 40-70 ribu kilometer jarak tempuh, sumber daya probe lambda dengan pemanasan secara signifikan lebih besar.

Probe sensor oksigen lambda, karena mempengaruhi komposisi campuran bahan bakar

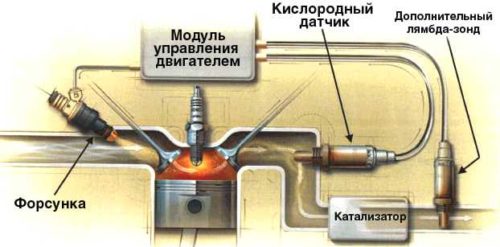

Setelah pembakaran bensin, gas-gas jatuh ke dalam kolektor buang, di mana sensor oksigen berada di depan katalis gas. Ini menghilangkan informasi karakteristik kualitatif dari knalpot, khususnya jumlah oksigen residu di dalamnya dibandingkan dengan kandungan 2 di udara atmosfer.

Indikator ini sangat penting karena dengan bantuannya komputer menghitung rasio bahan bakar dan oksigen optimal untuk membentuk campuran yang mudah terbakar dengan beban saat ini, untuk efisiensi motor tertinggi.

Pemasangan probe lambda kedua setelah katalis memungkinkan komputer dengan perhitungan yang lebih akurat, tetapi pada waktu kita jarang.

Perlu dicatat bahwa semua perhitungan didasarkan pada satu indikator penting - pembakaran efektif dari satu bagian bahan bakar mampu menyediakan 14,7 bagian oksigen.

Probe lambda, jenis perangkat

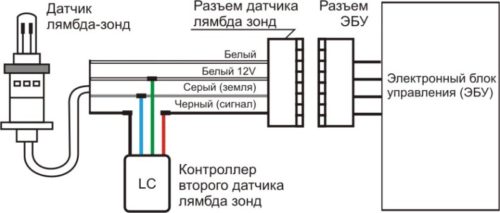

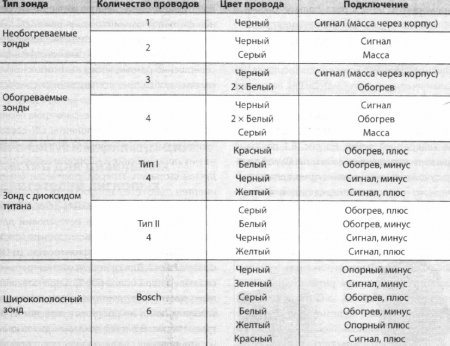

Bergantung pada jumlah kabel, yang dengannya sensor oksigen terhubung ke sistem, ada empat jenis perangkat ini:

- Empat kawat.

- Tiga kawat.

- Dua kawat.

- Satu kawat.

Sensor penyelidikan oksigen lambda, menyebabkan kerusakan dan yang mengancam mobil selama operasi

Untuk alasan, kerusakan sensor oksigen dapat dikaitkan:

- Cocok dengan perumahan dari cairan dan kotoran teknologi yang berbeda.

- Peningkatan kandungan timbal dalam pembakaran.

- Penggunaan bahan bakar dengan nomor oktan tinggi, yang tidak jarang menyebabkan overheating komponen probe lambda.

- Bahan bakar berkualitas buruk.

Ini dapat menyebabkan konsekuensi yang tidak menyenangkan, yaitu:

- Berkurangnya daya.

- Batang bergerak.

- Omset mengambang motor.

- Penampilan gas buang yang terkontaminasi berlebihan.

- Operasi katalis salah.

- Operasi injektor yang salah.

- Konsumsi bahan bakar yang bagus.

- Pada mobil dengan transmisi otomatis, ganti switching terjadi dengan mengetuk dan menyentak mobil.

Lambda menyelidiki, memeriksa kesehatan sensor dengan metode visual, penyebab dan konsekuensi:

kotoran, jelaga dan memanfaatkan sensor

Sebelum memeriksa sensor oksigen dengan bantuan perangkat, disarankan untuk terlebih dahulu memproduksi inspeksi visualnya untuk keberadaan kotoran, jelaga dan gar di sensor.

Alasannya adalah overheating dari probe lambda, pembakaran campuran yang mudah terbakar.

Konsekuensinya - respon hambat dari sensor oksigen, penerbitan akhir ini ke komputer dan switching tegangan terlambat.

deposisi sero-putih pada sensor

Penyebab - penggunaan aditif berbagai jenis bahan bakar dan minyak.

Konsekuensi - operasi sistem bahan bakar yang salah, diperlukan perangkat.

pada simpanan brilian sensor

Alasannya adalah banyak timbal dalam bahan bakar.

Konsekuensi - operasi sistem bahan bakar yang salah, diperlukan perangkat.

Sensor Oksigen Lambda Probe, memeriksa layanan dengan peralatan, operasi terperinci saat memeriksa voltmeter untuk campuran bahan bakar yang habis

Memeriksa sensor oksigen menggunakan instrumen hanya dalam hal cacat di atas tidak terdeteksi selama inspeksi visual. Kalau tidak, probe lambda hanya berubah menjadi yang baru.

Untuk mendiagnosis penyelidikan lambda menggunakan instrumen berlaku:

- Driver berpengalaman - osiloskop.

- Untuk pemeriksaan standar - voltmeter, lebih baik - digital.

- Yah, tentu saja, pengetahuan.

Selanjutnya, kami bertindak dengan cara ini:

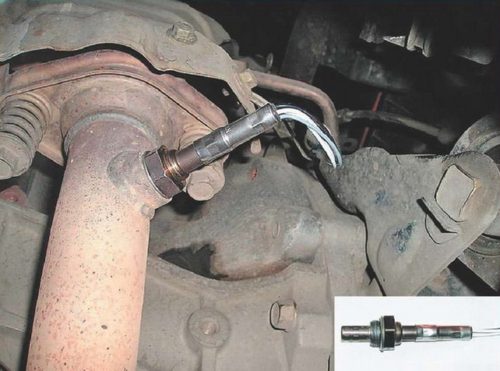

- Lepaskan koneksi probe lambda dari bantalan dengan kabel.

- Hubungkan ke voltmeter.

- Kami mulai dan menghangatkan motor.

- Kami meningkatkan kecepatan mesin hingga 2000-2600, setelah itu kami dengan tajam melemparkan pedal gas.

- Dari regulator tekanan vakum, lepaskan tabung.

- Kami mengukur tegangan, yang seharusnya 0,45-0,8 watt.

Dengan bantuan tabung dihapus dari regulator vakum, kami membuat pengering udara buatan. Ketika tegangan output kurang dari 0,2 W, maka sensor berfungsi.

Sebagai opsi, untuk memeriksa kinerja sensor oksigen, mengatur ulang ke kendaraan lain, asalkan konektornya cocok. Tidak jarang metode tes ini diterapkan di mana ada dua mobil dalam keluarga.

Periksa osiloskop, dekripsi grafik membaca

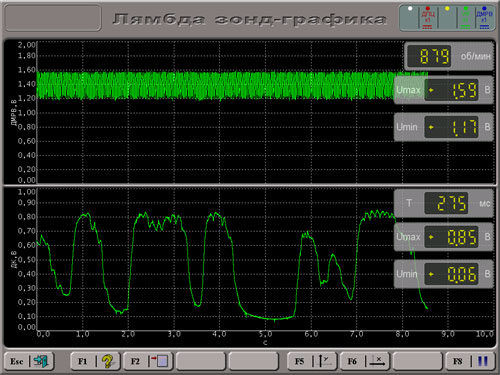

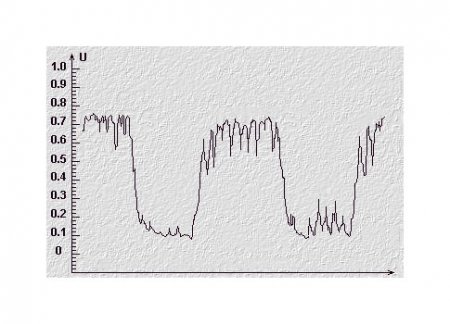

Keuntungan utama dari pemeriksaan ini adalah kemampuan untuk memperbaiki waktu di mana tegangan output diubah. Indikator penting ini hanya diperbaiki oleh osiloskop dan tidak boleh melebihi lebih dari 120 ms. Gambar di bawah ini menunjukkan operasi yang benar dari sensor oksigen.

Seperti yang Anda lihat, tegangan bervariasi lancar di kisaran 0,1-0,75 W. Namun, waktu dalam gambar tidak terlihat, karena sudah di atas, itu tidak boleh melebihi 120 ms. Gambar di bawah ini, ada gambar yang sama sekali berbeda.

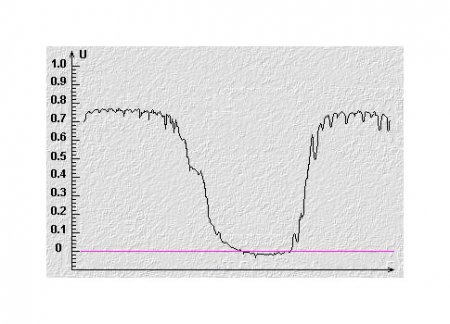

Di sini terlihat bahwa tegangan output turun di bawah 0-1 W. Ini menunjukkan bahwa penyelidikan lambda rusak dan harus diganti. Dengan rincian sensor oksigen, di dasbor, sebagai aturan, "periksa mesin" menyala.

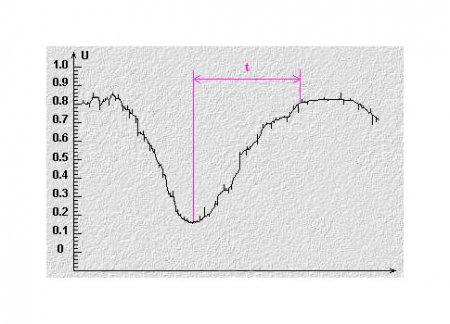

Pada gambar ini, reaksi gerakan lambat dari lambda-probe pada perubahan jumlah oksigen dalam knalpot ditunjukkan oleh osiloskop. Jelas melebihi 120 ms. Sistem kontrol mobil tidak mampu menentukan kegagalan fungsi ini, dan kesalahan mesin periksa tidak muncul di dasbor. Konsekuensi utama dari kerusakan ini adalah untuk mengurangi kekuatan motor dan peningkatan konsumsi bahan bakar.

Tips Pro: Cara Memeriksa dengan Benar

Semua cek dibuat hanya pada motor panas dengan revolusi 2000-2600. Tidak seperti memeriksa dengan voltmeter, di mana probe lambda harus dimatikan dari controller, ketika memeriksa osiloskop, sensor oksigen dari jaringan tidak diperlukan.

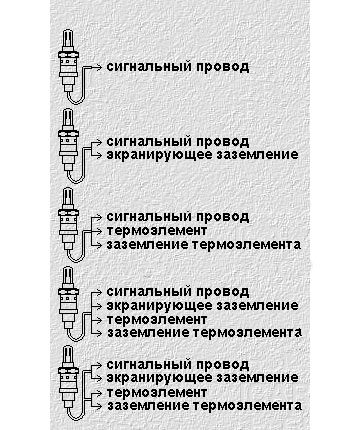

Probe osiloskop terhubung ke kawat peringatan 2-sensor dan bacaan dihapus. Lokasi konektor dapat dilihat pada gambar di bawah ini.

Pada angka berikut ini Anda dapat berkenalan dengan konektor sensor oksigen, warna kabel dan koneksi mereka.

Kesimpulan dan rekomendasi

Perlu untuk memeriksa sensor oksigen, karena konsekuensi dari kerusakannya bisa sangat penting, serta sepenuhnya menghentikan kendaraan. Saat mengganti perangkat ini, lebih baik menggunakan analog baru, karena komputer mesin Anda sudah disesuaikan untuk menerima sinyal dari model ini.

Meskipun perlu dicatat bahwa beberapa pemilik mobil masih mempertaruhkan dan berkumpul bukannya sensor oksigen mahal yang rusak. Misalnya, untuk mobil Moskvich, Vaz tentang 2-sensor menghasilkan Bosh. Dia juga memproduksinya untuk mobil Ford, jadi standar kualitas Eropa. Akibatnya, untuk kendaraan Ford Anda dapat membeli analog perangkat yang dibuat untuk mobil Vaz. Yang paling penting adalah jumlah kontak sama.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips berguna

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips berguna

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat menggerakkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar