Jika kompor di mobil Anda VAZ 2110 berhenti menghangatkan salon, ada kemungkinan bahwa demam motor damper motor gagal. Saat mengganti pegangan pemanas, motor yang rusak tidak menggerakkan peredam, sebagai akibatnya menjadi dingin di dalam mobil. Untuk memeriksa kinerja perangkat VAZ 2110 Heater Motor, Anda harus membongkarnya. Tentang ini lebih lanjut dalam artikel.

Isi

- Perangkat motor pemanas 2110, perangkat dan prinsip operasi

- Motor motor vaz, tanda-tanda kerusakan pada motor deuktor, alasan

- Alat, perlengkapan, bahan habis pakai untuk bekerja

- Motor motor mikro 2110, penggantian (instruksi langkah demi langkah)

- Motor Motor Heater Tanders 2110, Instalasi dengan tangan Anda sendiri, instruksi langkah demi langkah

- Memeriksa kinerja

Perangkat motor pemanas 2110, perangkat dan prinsip operasi

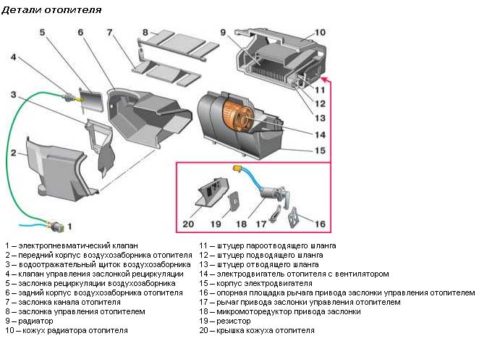

Motor Deuctor membuka dan menutup katup pemanas menggunakan sinyal sistem kontrol, sebagai akibat dari udara yang memasuki kabin dipanaskan atau didinginkan. Tergantung pada tahun kendaraan, konfigurasi deductor motor mungkin berbeda secara signifikan.

Unit ini terletak di ruang kemudi dari sisi kemudi. Tidak sulit untuk menemukannya, karena dipasang di dekat penguat rem.

Motor motor vaz, tanda-tanda kerusakan pada motor deuktor, alasan

Jika Anda tidak dapat mengontrol suhu udara di kabin menggunakan pegangan, pertama-tama Anda perlu memeriksa motor pemanas. Pemeriksaan kinerja dilakukan dengan posisi tengah pegangan dengan cara memasok tegangan dari baterai ke unit. Dengan cara ini, Anda dapat memeriksa keadaan controller, kegagalan yang juga tidak memungkinkan Anda untuk menyesuaikan suhu.

Penyebab kegagalan perangkat ini:

- Kerusakan di blok otonom, yang mengelola pemanas, sebagai akibat dari mana gearbox tidak menyediakan suhu optimal kompor.

- Gangguan integritas sirkuit listrik, sebagai akibat dari mana tegangan yang disediakan dari baterai tidak pergi ke mesin, sebagai akibat dari mana motor deuctor tidak dapat bekerja secara normal.

Alat, perlengkapan, bahan habis pakai untuk bekerja

- Obeng palang pendek.

- Satu set kunci.

- Sikat untuk membersihkan elemen.

- Kepala-kepala dengan ratchet pada "10".

- Silang obeng.

- Pegangan magnetik.

Motor motor mikro 2110, penggantian (instruksi langkah demi langkah)

Jika mikromotractor diperlukan pada VAZ 2110, beberapa peristiwa sederhana harus diadakan. Anda harus membongkar simpul pedal, jabro dan vut. Kemudian bongkar kompor motor lama dengan elemen plastik dan instal mictotortoctor baru alih-alih sektor peredam, di mana ada kotak yang sama. Sebagai aturan, penggantian gearbox dibuat tanpa kesulitan khusus.

Instalasi katup mikromotor harus dilakukan dengan asisten. Pertama-tama hubungkan kontak ke motor baru. Mengubah flap pemanas berlawanan arah jarum jam menunjukkan pasokan udara dingin, jadi pengapian harus dihidupkan, kemudian mentransfer sensor sistem kontrol pemanas di seberang titik biru.

Anda juga dapat dibuat sebaliknya - putar flap sampai Anda berhenti searah jarum jam, dan sensor diterjemahkan di seberang titik merah. Setelah itu, mikrosesor kompor akan berubah lebih diperlukan. Untuk menginstal adalah normal, gunakan pelumas khusus untuk kotak.

Atur motor sedemikian rupa sehingga lubang untuk sekrup bertepatan. Kemudian asisten harus menggulir pengontrol suhu dan pada saat yang sama menekan motor. Jika kuadrat bertepatan, maka penggantian berhasil, dan gearbox akan memberikan aliran udara yang diinginkan.

Jika alun-alun hanya datang pada sepertiga peredam, tidak ada yang mengerikan, itu tidak akan mempengaruhinya. Maka Anda perlu mengacaukan sekrup dan menggulir gearbox beberapa kali - dari tanda merah ke biru dan sebaliknya. Itu harus dilakukan agar sistem mengingat rentang operasi, sebagai akibatnya motor akan berfungsi dengan baik.

Motor Motor Heater Tanders 2110, Instalasi dengan tangan Anda sendiri, instruksi langkah demi langkah

Untuk mendapatkan akses ke sektor motor, Anda pertama-tama perlu menghapus wiper.

Maka Anda perlu membuka kontak kontak dan melepaskan jab, setelah akses ke gambar sendiri akan terbuka. Selanjutnya, buka 2 kacang di sisi jabium dan tarik keluar sealer karet dari kompartemen elektronotor.

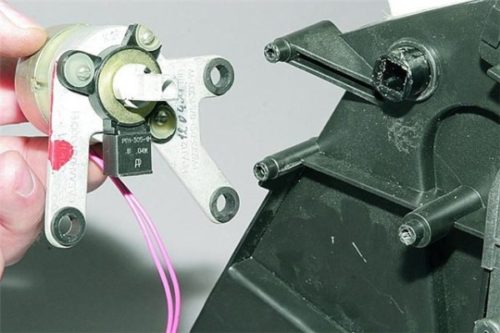

Pertama, kami memutuskan sambungan pipa flap, setelah itu kami membuka sekrup yang menahan radiator termal dari gearbox. Mesin ini terletak di sisi kiri gearbox flap, dekat penguat rem. Buka dua baut di kompartemen atas.

Selanjutnya, lepaskan sekrup dari bawah dan bongkar motor listrik. Bangun produk peredam dalam urutan terbalik.

Memeriksa kinerja

Untuk memeriksa gearbox, atur posisi kompor di pegangan kiri pada titik biru, tunggu 10 detik dan mulai motor. Controller memutuskan dari konektor X1 dan menguji resistansi pada kontak X1.1 dan x1.4. Motor Deuctor harus memiliki tegangan 800-1200 ohm untuk pengontrol 1333.3854, 1313.3854, 1303.3804, dan untuk controller 1323.3854 - 3600-5000 ohm.

Sekarang kami menguji mikromotor di posisi kompor pada titik merah. Gearbox harus memiliki resistensi ohm 3200-5000 untuk pengontrol 1333.3854, 1313.3854, 1303.3854, dan untuk controller 1323.3854 - 1200-1600 ohm.

Jika resistansi tidak berubah atau tidak sama sekali, ini menunjukkan keunikan sensor posisi poros. Itu tidak dapat dibeli secara terpisah, jadi dalam hal ini Anda harus sepenuhnya mengubah gearbox.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips bermanfaat

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat menggerakkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar