Pengendara yang berpengalaman selalu terasa seperti kendaraan berperilaku di jalan, dan, berdasarkan fitur individu, menentukan sistem mana yang akan didiagnosis. Jika penyimpangan di jalan semakin terasa di kabin mobil, maka kemungkinan besar sudah waktunya untuk memeriksa suspensi atau komponenya masing-masing. Tentang ini lebih lanjut dalam artikel.

Isi

- Peredam kejut, perangkat dan tujuan

- Memeriksa peredam kejut, apakah mungkin untuk membagi tubuh, modern otomatis, periksa kekuatan shock absorber

- Syok absorber tidak bekerja masalah yang mengancam mobil dan pengemudi jika shock absorber gagal

- Memeriksa peredam kejut, bagaimana cara memeriksa bantuan shock absorber dengan kekuatannya sendiri tanpa membongkar peredam kejut

- Cara Memeriksa Shock Absorber pada Kinerja Menggunakan Perangkat dengan Sensor Gerakan

- Uji kejut (uji shock) diagnostik dari peredam kejut

- Mengekspresikan diagnosa dari peredam kejut

- Memeriksa beban amplitudo peredam kejut dengan cara resonansi

- Peredam kejut baru, bagaimana cara memeriksa shock absorber di tempat pembelian dari penjual

- Tips Prof.

Peredam kejut, perangkat dan tujuan

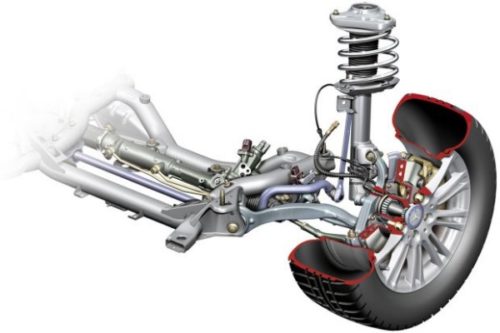

Shock Absorber dirancang untuk memuaskan kesal dan guncangan, yang saat bergerak menerima bodi mobil dengan menggunakan roda. Selain itu, peredam kejut memberikan kontak yang andal dari roda kendaraan dengan roadpaper. Jadi tujuan mereka bukan hanya kenyamanan, tetapi keamanan.

Sebelumnya, mobil tidak dilengkapi dengan peredam kejut. Fungsi mereka dilakukan oleh pegas - pendinginan getaran dibuat karena gesekan lembaran menjadi satu sama lain. Kecepatan dengan mobil mana yang dapat bergerak terus tumbuh, sebagai hasil dari mana sistem baru harus berkembang untuk keselamatan dan kenyamanan. Dengan demikian, rak ada dalam bentuk blok cakram gesekan terkompresi, yang bekerja sebagai berikut: Getaran padam dengan mengorbankan upaya, yang dengan cakram diputar relatif satu sama lain. Setelah beberapa waktu, perlu untuk meninggalkan desain seperti itu, karena cakram dengan cepat mengenakan dan terlalu panas.

Pada usia 20-an abad kedua puluh, output ditemukan. Solusi untuk masalah adalah penggunaan cairan yang memiliki getaran tubuh, bergerak dari satu tangki ke tangki lainnya di bawah tekanan.

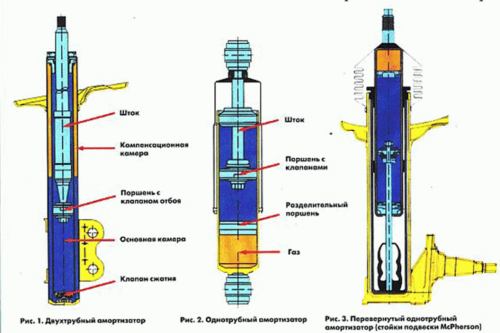

Dengan desainnya, rak dapat dibagi menjadi sejumlah variasi utama. Dalam struktur, mereka, sebagai aturan, adalah satu-tabung dan dua-pipa.

Peredam kejut dibedakan oleh jenis cairan, yang diisi - gas (dengan subpoda hidrolik gas) dan hidrolik. Hanya ada peredam kejut gas, tetapi mereka sangat jarang digunakan. Gas di dalamnya berada di bawah tekanan tinggi (sekitar 60 ATM).

Pengoperasian peredam kejut adalah resistensi hidrolik atau resistensi gas. Minyak bertindak sebagai cairan. Ada varietas rak di mana, selain minyak, resistansi memberikan gas dan gas tekan.

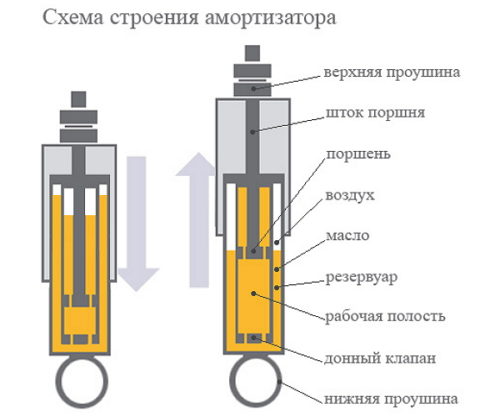

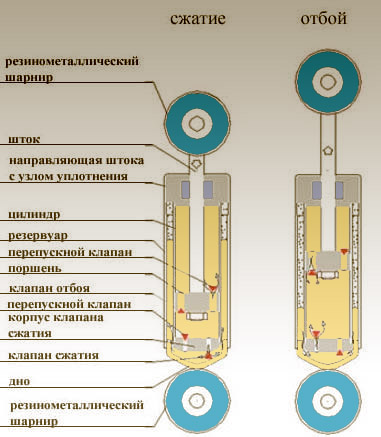

Syok absorber itu sendiri dibagi secara kondisional menjadi piston dan silinder. Di dalam silinder, tergantung pada modifikasi, ada ruang - atau dengan gas dan mentega, atau dengan udara dan minyak. Dalam kedua kasus, piston berjalan di dalam silinder, jatuh dan naik. Dalam kasus kedua, piston menolak tekanan yang dihasilkan oleh ruang gas tekan. Dalam yang pertama - piston bergerak dengan resistance, yang terjadi sebagai akibat dari aliran minyak dengan menggunakan katup ke dalam ruangan lain.

Memeriksa peredam kejut, apakah mungkin untuk membagi tubuh, modern otomatis, periksa kekuatan shock absorber

Sebelumnya, pada model-model lama mobil klasik dengan jenis dan model peredam kejut sebelumnya, kemudahan servis rak dapat ditentukan sangat sederhana - dengan bantuan sekelompok tubuh. Desain kompleks dari suspensi otomotif modern tidak memungkinkan secara visual untuk membuat kesimpulan objektif tentang bantuan peredam kejut. Namun, ada banyak metode efektif lainnya yang akan kita pertimbangkan di bawah ini.

Syok absorber tidak bekerja masalah yang mengancam mobil dan pengemudi jika shock absorber gagal

Kerusakan utama dari peredam kejut adalah perubahan dalam parameter operasionalnya, yang terjadi sebagai akibat dari gangguan sesak, kerusakan mekanis atau keausan elemen-elemen kerja (batang) dari shock absorber.

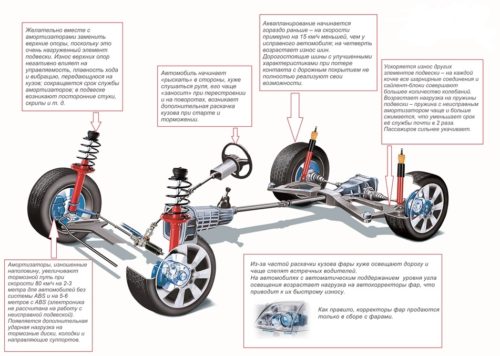

Kerusakan peredam kejut mengarah pada konsekuensi berikut:

- Pelanggaran pengelolaan mobil. Ingat ekspresi "Saya tidak mengatasinya dengan kontrol ...". Beberapa driver terkadang terkejut - yah, bagaimana saya bisa menanganinya dengannya? Bahkan, semuanya sederhana: ketika memutar rotasi pada kecepatan, peredam kejut yang rusak membuat mobil secara spontan bergerak dari logam.

- Mengurangi kapasitas beban.

- Mengurangi stabilitas kendaraan kursus.

- Meningkatkan jalur rem, risiko "perawatan" ke samping dengan pengereman ekstrem atau menengah.

- Akselerasi keausan dan kerusakan komponen suspensi tersebut, seperti dukungan rak, mata air, blok diam, bantalan hub, shreh, dan sebagainya.

- Memburuknya kenyamanan perjalanan.

Memeriksa peredam kejut, bagaimana cara memeriksa bantuan shock absorber dengan kekuatannya sendiri tanpa membongkar peredam kejut

Sangat penting bahwa metode ini hanya dapat memeriksa bantuan peredam kejut, daripada kinerjanya. Korespondensi rak oleh karakteristik teknis pabrikan adalah percakapan terpisah.

Anda dapat secara mandiri memeriksa bantuan peredam kejut tanpa membongkar Anda hanya dapat secara visual - untuk mendiagnosis adanya kerusakan mekanis (mis. Dent) dan kebaikan ketat.

Jika kebocoran dan noda minyak diamati pada perumahan peredam kejut, segera keluarkan kesimpulan bahwa segel usang, yang menunjukkan munculnya peredam kejut.

Orang-orang ada pendapat bahwa minyak "kabut" pada kasus ini adalah kerusakan, tetapi tidak. Ketika shock absorber berjalan, labu ini dianggap sebagai fenomena normal.

Ketika melaksanakan diagnosis peredam kejut, setelah membongkar, perlu untuk memberikan perhatian khusus pada batang - seharusnya tidak menjadi jaket, jejak korosi A, terutama deformasi.

Cara Memeriksa Shock Absorber pada Kinerja Menggunakan Perangkat dengan Sensor Gerakan

Perangkat ini "manual". Itu melekat pada sayap mobil, dan sensornya diletakkan di tanah. Tubuh memberi bayangan informasi. Pada saat yang sama, parameter pabrik diperkenalkan ke perangkat, yang merupakan kecepatan peredam kejut. Kinerja rak didiagnosis dalam rasio persentase.

Uji kejut (uji shock) diagnostik dari peredam kejut

Tes kejut diproduksi pada dudukan khusus. Roda sumbu harus diangkat dan jatuh tajam. Komputer mendaftarkan koefisien atenuasi osilasi rak.

Mengekspresikan diagnosa dari peredam kejut

Diagnostik ekspres memberikan pengereman tajam. Itu dilakukan dengan dudukan dengan platform khusus. Pada saat yang sama, sistem rem diperiksa. Mobil harus memasuki platform dan rem dengan tajam. Fluktuasi tubuh mobil diperbaiki, serta beban pada sensor platform. Meskipun keakuratan metode ini membuat banyak yang diinginkan.

Memeriksa beban amplitudo peredam kejut dengan cara resonansi

Memeriksa peredam kejut Metode resonansi amplitudo didasarkan pada analisis amplitudo (yaitu, nilai-nilai gerakan) platform dengan roda kendaraan yang dipasang di atasnya. Platform ini dilaporkan oleh osilasi yang frekuensinya sekitar 16 Hz. Ketika data dilemahkan, osilasi terjadi resonansi - peningkatan amplitudo osilasi ketika frekuensi fluktuasi platform dan frekuensi suspensi kendaraan sendiri. Nilai-nilai yang lebih besar dari amplitudo mencapai, semakin buruk memadamkan osilasi peredam kejut. Selanjutnya, stand membandingkan hasil pengukuran dengan data referensi, setelah itu masalah kesimpulan tentang kinerja peredam kejut.

Peredam kejut baru, bagaimana cara memeriksa shock absorber di tempat pembelian dari penjual

- Di luar ruangan, inspeksi visual. Periksa tanda. Itu harus cocok dengan katalog pabrikan. Selanjutnya, Anda perlu memeriksa shock absorber untuk keberadaan berbagai kerusakan mekanis pada kelenjar, perumahan, batang dan sebagainya. Periksa koneksi berulir. Tentu saja, seharusnya tidak ada inklusi minyak.

- Memeriksa kepatuhan geometris. Anda membutuhkan caliper dan penguasa. Perlu untuk memeriksa panjang dalam keadaan shift, diameter batang dan batang batang (Orient atau pada rekomendasi pabrikan, atau untuk menyimpang dari nilai nominal - ± 5 mm).

- Memeriksa kinerja shock absorber. Tabung tunggal diperiksa tanpa persiapan sebelumnya. Mereka harus dikompresi dan diregangkan selama sekitar 3-5 kali. Rod harus bergerak dengan lancar, tanpa kesal dan jamming yang tajam, dengan upaya yang sama. Seharusnya tidak ada keributan dan kebisingan asing, selain "saran" alami, yang merupakan hasil dari aliran cairan di dalam rak. Pipa ganda harus disiapkan untuk pra-persiapkan - memompa beberapa kali (3-5), memasang secara vertikal, setelah itu tidak mengubah peredam kejut.

Tips Prof.

Mendiagnosis masalah yang dikaitkan dengan pekerjaan peredam kejut sangat sederhana - mobil terasa gemetar ketika menyentuh benjolan, tapping karakteristik terdengar. Masalah utama yang terkait dengan kedatangan perangkat ini menjadi rusak adalah bahwa proses ini terjadi secara bertahap (pengecualian adalah peredam kejut gas dan minyak, yang disebabkan oleh desainnya, dapat gagal secara instan). Jadi, pengendara dapat beradaptasi dengan perilaku mesin tersebut dan tidak terburu-buru untuk memperbaiki. Namun, sementara itu, keausan ban dan jalur pengereman meningkat, kemudi lebih buruk. Tampaknya bagi Anda bahwa ini adalah hal-hal kecil, tetapi, di sisi lain, dalam kasus darurat, kerusakan peredam kejut dapat secara signifikan mempengaruhi hasilnya.

Perlu dicatat bahwa dalam transportasi, yang dilengkapi dengan sistem pengereman elektronik (EBD, ABS, dan sebagainya), peredam kejut yang rusak tidak akan jarang menyebabkan kegagalan malail.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis untuk PlaneCitel

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips bermanfaat

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat menggerakkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar