Pengoperasian mesin dan normal dari mesin tergantung pada kebenaran pengaturan momen pengapian. Oleh karena itu, acara ini adalah salah satu proses paling penting untuk menyiapkan unit daya. Pengapian yang salah diinstal (seperti ke arah peningkatan sudut di depan dan ke arah penurunannya), pada kenyataannya, segera dapat mempengaruhi pengoperasian motor. Oleh karena itu, operasi ini harus terkait dengan kesempurnaan khusus dan perhatian untuk mencegah terjadinya darurat atau dini. Tentang ini lebih lanjut dalam artikel.

Isi

- Pengapian otomatis, perangkat, dan prinsip

- Lebih awal dan kemudian menyalakan apa artinya

- Tanda-tanda pengapian dini

- Tanda-tanda penyalaan terlambat

- Sudut instalasi pengapian, tanda-tanda sudut pengapian yang tidak teratur

- Perubahan sudut pengapian, yang konsekuensi dari operasi mobil dengan pengapian yang salah

- Apa yang seharusnya menjadi sudut muka pengapian, menyesuaikan sudut pada siaga

- Stroboscope yang Anda gunakan

- Mengatur pengapian untuk instruksi strobo, langkah demi langkah

- Mengatur kunci kontak pada lampu kontrol

- Mengatur pengapian dalam percikan, dalam hal kinerja mesin

- Profil Profi, Cara Memeriksa Kualitas Penyesuaian Angle Advance (UAZ)

Pengapian otomatis, perangkat, dan prinsip

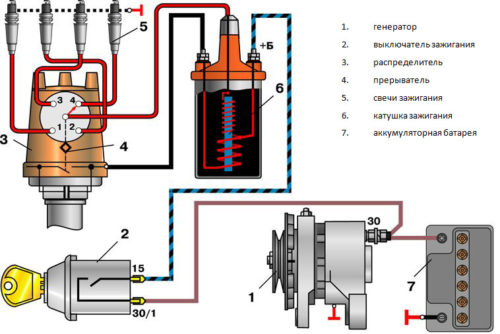

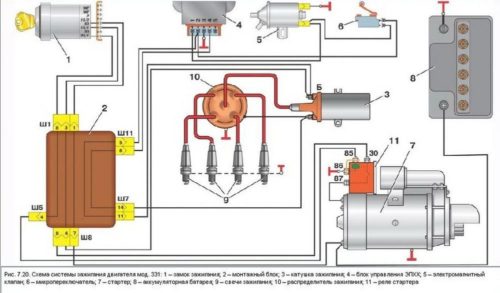

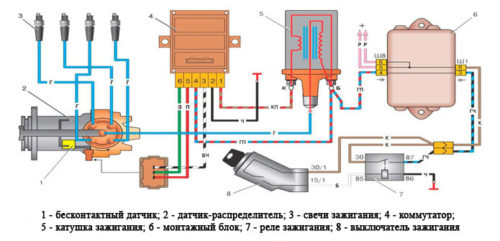

Tujuan dari sistem pengapian adalah pengapian campuran bahan bakar udara dari mesin bensin. Pengapian campuran dilakukan dari percikan, sehingga sistem yang berbeda juga disebut sistem percikan peringkat. Tergantung pada metode mengendalikan proses pengapian, ada variasi sistem pengapian - elektronik (mikroprosesor), non-kontak (transistor), kontak.

Dalam sistem kontak, sistem kontrol akumulasi, serta distribusi listrik di atas silinder, dilakukan dengan menggunakan perangkat mekanis - distributor distributor. Pengembangan selanjutnya dari sistem pengapian ini adalah sistem kontak transistor, rantai utama koil pengapian yang melibatkan penggunaan saklar transistor.

Dibandingkan dengan sistem kontak, dalam sistem pengapian tanpa kontak, sakelar transistor digunakan untuk mengontrol akumulasi energi, yang berinteraksi dengan sensor pulsa tanpa kontak. Saklar transistor dalam sistem ini memainkan peran pemutus. Adapun distribusi arus tegangan tinggi, dilakukan menggunakan distributor mekanis.

Unit kontrol elektronik digunakan dalam sistem elektronik, yang dengannya kontrol akumulasi dan distribusi listrik dilakukan. Pada struktur awal sistem ini, unit elektronik secara bersamaan mengelola sistem injeksi bahan bakar dan sistem pengapian (yang disebut sistem pengapian elektronik dan injeksi). Sampai saat ini, manajemen pengapian dimasukkan dalam sistem kontrol mesin.

Namun, terlepas dari perbedaan struktural, Anda dapat memilih sistem ventilasi bersama:

- Busi.

- Kabel tegangan tinggi.

- Perangkat distribusi energi (unit kontrol elektronik atau distributor mekanis).

- Penyimpanan Energi (i.e. koil pengapian).

- Perangkat yang mengendalikan akumulasi energi (dalam berbagai sistem pengapian, peran ini melakukan unit kontrol elektronik, transistor switch atau interrupter).

- Saklar pengapian.

- Catu daya (baterai dan generator otomotif).

Pengoperasian sistem pengapian memberikan langkah-langkah berikut:

- Akumulasi listrik.

- Konversi energi.

- Distribusi energi ini.

- Pembentukan percikan.

- Radang campuran bahan bakar udara.

Lebih awal dan kemudian menyalakan apa artinya

Pengapian dini dibedakan oleh fakta bahwa prosedur pembakaran bahan bakar diesel berakhir bahkan sampai piston datang ke posisi yang diperlukan. Area, sedangkan di dalam loop, dianggap setara dalam kaitannya dengan pekerjaan negatif. Dan ini disebabkan oleh fakta bahwa selama kompresi gas, proses pembakaran yang telah terjadi, menghabiskan lebih banyak kekuatan, daripada muncul setelah ekspansi mereka.

Nanti kunci kontak tidak kurang berbahaya daripada awal. Fitur utamanya adalah bahwa prosedur pembakaran campuran dilakukan pada tingkat volume yang meningkat dan tingkat tekanan berkurang di silinder. Dalam situasi ini, campuran di jalur silinder sepanjang proses ekstensi.

Tanda-tanda pengapian dini

- Detonasi berlebihan (penghancuran batang, cacat piston).

- Ketukan terdengar dengan baik di unit daya (pemakaian tinggi).

- Peningkatan konsumsi bahan bakar.

- Kehilangan daya (terutama terlihat pada revolusi kecil).

Tanda-tanda penyalaan terlambat

- Mesin overheating (dapat meningkatkannya).

- Peningkatan konsumsi bahan bakar.

- Awal yang buruk (menghasilkan baterai menderita).

- Kehilangan daya.

Sudut instalasi pengapian, tanda-tanda sudut pengapian yang tidak teratur

- Ledakan.

- Tembakan dalam karburator atau di muffler.

- Menjadi terlalu panas.

- Mencelupkan ketika ditekan pada pedal gas.

- Idle lemah.

- Mengurangi level daya dan pickup.

- Peningkatan konsumsi bahan bakar.

- Masalah dengan awal.

Perubahan sudut pengapian, yang konsekuensi dari operasi mobil dengan pengapian yang salah

Pengapian terlalu dini atau lambat adalah gejala penghentian operasi normal mesin. Agar motor memberikan kekuatan yang diperlukan, percikan di silinder harus datang hanya ketika seluruh kekuatan konsistensi tanpa pengap, dikompresi saat ini di silinder, dapat digunakan hingga batas maksimum.

Jika Anda mengirimkan percikan dalam waktu yang tidak perlu, konsistensi akan mengabaikan atau sangat awal (dalam hal ini, bagian tertentu dari energi akan berlaku terhadap gerakan piston), atau sangat terlambat (dalam hal ini, bagian tertentu Energi akan dirilis oleh pipa knalpot). Untuk alasan ini, pemilik mobil berkewajiban untuk membedakan antara gejala-gejala awal dan akhir pengapian, serta untuk mencegah munculnya fenomena ini.

Apa yang seharusnya menjadi sudut muka pengapian, menyesuaikan sudut pada siaga

Sudut muka pengapian harus optimal, yaitu, tidak terlalu dini dan belum terlambat. Menyesuaikan momen pengapian saat idle adalah sebagai berikut (mesin, pada saat yang sama, harus dipanaskan):

- Lemah kacang yang memperbaiki tubuh pemangkas, setelah itu mulai berputar perlahan di sisi yang berbeda.

- Dalam posisi di mana pergantian motor akan paling maksimal, Anda harus mencoba "melunasi". Jika selama penekan tajam pada pedal tidak akan ada tembakan, kapas dan interupsi, dan turnoves akan cepat berakselerasi, itu berarti bahwa posisi yang diperlukan ditemukan.

- Dari titik ini, periksa perumahan dispenser untuk satu atau dua derajat searah jarum jam, dan kemudian clamp retainer-nya. Barang terakhir harus dilakukan bahwa pengapian tidak terlalu "lebih awal", menghasilkan resistensi yang berlebihan terhadap rotasi crankshaft.

Stroboscope yang Anda gunakan

Tujuan utama dari strobo otomotif adalah menyesuaikan sudut muka pengapian. Selain itu, stroboscope digunakan untuk memeriksa sudut depan. Di zaman kita, kita membuat banyak varietas stroboskop otomotif profesional. Namun, perangkat buatan sendiri dapat dibuat.

Mengatur pengapian untuk instruksi strobo, langkah demi langkah

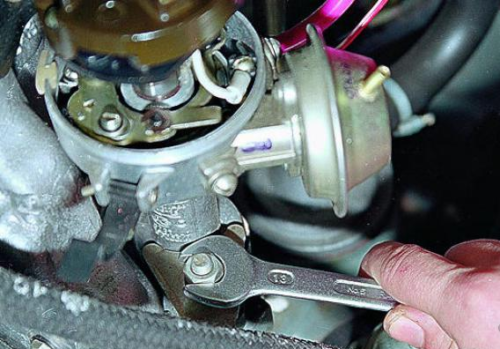

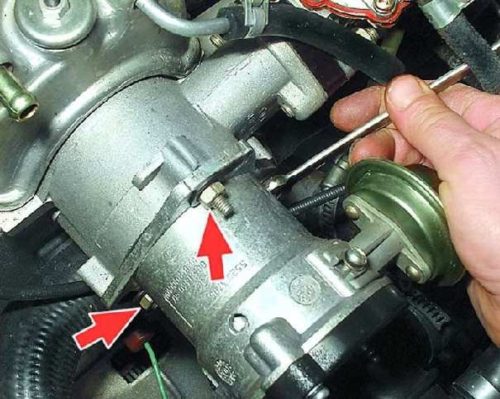

- Pertama-tama, menggunakan kunci untuk "13", kita harus melemahkan kacang pengikat berlarut-larut dari plat distribusi pengapian.

- Selanjutnya, kami menghubungkan strobo ke baterai ke terminal "plus" menghubungkan penjepit perangkat yang diinginkan (dengan tanda plus), dan kami melampirkan massa ke terminal "minus".

- Jika sistem memiliki regulator canggih vakum, itu berarti Anda perlu membongkar selang vakum.

- Maka Anda perlu fokus pada lampu katrol dari perangkat.

- Sekarang unit daya harus diluncurkan dan memastikan jumlah revolusi sekitar 820-900 per menit.

- Dalam proses kerja, strobo akan memancarkan lampu flash dalam frekuensi tertentu, yang akan memungkinkan Anda untuk melihat tanda pada katrol yang tidak akan bergerak.

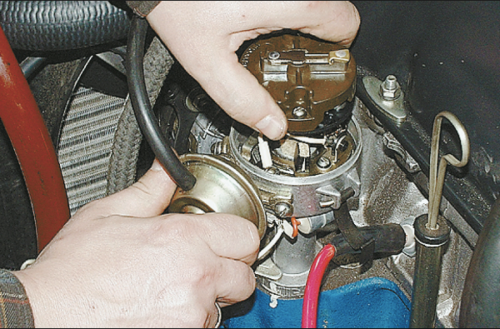

- Setelah itu, perlu untuk membungkus tubuh dispenser sedemikian rupa sehingga tanda ini pada pulley berada pada level yang sama dengan divisi rata-rata pada tutupnya.

- Nah, hal terakhir yang harus dilakukan adalah mengencangkan mur pemasangan pelat interrupter dispenser.

Mengatur kunci kontak pada lampu kontrol

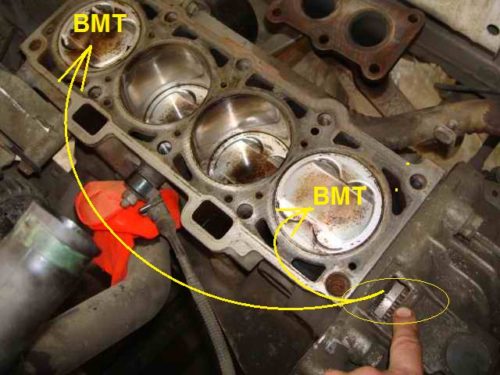

- Kami memutar crankshaft sedemikian rupa sehingga label pulley bertepatan dengan label yang diperlukan pada penutup waktu, dan pelari interupter pengapian menunjukkan kawat tegangan tinggi dari silinder pertama.

- Selanjutnya Anda perlu melemahkan mur yang memperbaiki tubuh pemangkas.

- Kemudian satu kawat lampu kontrol terhubung ke kawat, yang menuju ke koil pengapian dari traver, dan yang lainnya ke "massa" kendaraan.

- Pastikan untuk memasukkan pengapian.

- Setelah itu, putar rantai traver searah jarum jam sampai cahaya padam.

- Kemudian perlahan-lahan putar karet ke sisi lain, yaitu berlawanan arah jarum jam.

- Perbaiki posisi traver di mana lampu kontrol menyala.

- Kencangkan kacang pengikat interrupter dispenser.

Mengatur pengapian dalam percikan, dalam hal kinerja mesin

- Kami memutar crankshaft sedemikian rupa sehingga label pulley bertepatan dengan label yang diperlukan pada penutup waktu, dan pelari interupter pengapian menunjukkan kawat tegangan tinggi dari silinder pertama.

- Selanjutnya, Anda perlu melemahkan kacang, yang memperbaiki perumahan interrupter pengapian.

- Lepaskan kawat tegangan tinggi pusat dari penutup tumbler, dan kontaknya terletak pada jarak lima milimeter dari massa kendaraan.

- Nyalakan kunci kontak.

- Searah jarum jam mengubah tubuh interrupter selama dua puluh derajat.

- Perlahan putar karet ke sisi lain.

- Perbaiki posisi traver, di mana ada percikan tentang massa dan kontak dari kawat pusat.

- Kencangkan mur pengunci dari interrupter.

Profil Profi, Cara Memeriksa Kualitas Penyesuaian Angle Advance (UAZ)

Untuk memeriksa apakah uang muka pengapian dikonfigurasi dengan benar, Anda harus dipandu oleh fitur-fitur berikut:

- Dalam pekerjaan unit daya yang dipanaskan, tidak ada "kegagalan" pada idle tidak boleh dirasakan.

- Sebuah detonasi pendek (sekitar 3-5 detik) harus hadir jika gerakan tajam ditekan pada pedal gas, pergerakan harus terjadi pada bagian paling rata dari lapisan jalan dengan gigi keempat dan kecepatan sekitar 50 kilometer per jam. Artinya, ketukan jari harus didengar. Jika ini tidak terjadi, maka pengapian sudah terlambat. Jika fenomena ini diamati, tetapi tidak berlalu, pengapiannya terlalu dini.

Bahan terkait

- Kompor 2110, Kompor Hangat Buruk 2110, VAZ 2110 Sistem Pemanas, Memperbaiki Sistem Pemanas VAZ 2110 dengan tangan mereka sendiri

- VAZ 2114 kompor pukulan dengan udara dingin, kompor 2114, kompor hangat buruk VAZ 2114, perangkat dan perbaikan pemanasan vaz 2114 do-it-yourself, menghapus kompor vaz 2114

- Cara subdominize mobil. Cara meletakkan jack. Jenis jack untuk mobil.

- VAZ 2109 Blok Sekering, VAZ 2109 Fuse Block Carburetor, VAZ 2109 Fuse Block Injector, Blok Sekering VAZ 2109, VAZ 2109 Fuse Block, VAZ Fuse Block 2109

- Katalis gas buang mobil, katalis yang rusak, plus dan kontra dari katalis, cara mengubah katalis di pesawat

- Kompor meniup udara dingin VAZ 2114, dengan buruk meniup kompor VAZ 2114, mengapa dengan buruk meniup kompor VAZ 2114

- Cara mencari tahu pemilik mobil dengan jumlah mobilnya, periksa mobil dengan jumlah mesin polisi lalu lintas, periksa mobil dengan jumlah negara mobil secara gratis

- Cara Memilih Ban Digunakan, Tips Berguna

- Jalan mobil musim dingin, tekanan dalam ban mobil penumpang di musim dingin, baterai yang baik untuk mobil di musim dingin, apakah akan menghangatkan mobil di musim dingin

- Di musim dingin, mobil ini dimulai dengan buruk. Cara membuat mobil di musim dingin, apakah Anda perlu menghangatkan mobil di musim dingin, tips bermanfaat

- Mesin konsumsi bahan bakar ekonomi, konsumsi mobil paling ekonomis

- Merek Ban untuk Mobil Penumpang, Pelabelan Label Ban Mobil, Pelindung Ban Mobil Penumpang Residual, Cara Memilih Ban Pada Merek Mobil, Pola Tapak Ban Mobil

- Operasi transmisi yang berfungsi, pekerjaan gearbox gearbox, mengemudi dengan gearbox manual, tips bermanfaat

- Balok belakang peugeot 206 sedan, perangkat balok belakang Peugeot 206. Balok belakang peugeot 206 kerusakan, perbaikan balok belakang peugeot 206

- Bahan bakar diesel di musim dingin, aditif untuk bahan bakar diesel di musim dingin, bagaimana memilih bahan bakar diesel terbaik

- Diesel musim dingin tidak dimulai. Cara memulai diesel di musim dingin, pemanas diesel di musim dingin.

- Ban Bridgestone Jepang, Ban Bridgestone bertabur musim dingin, Merek Ban Bridgestone

- Penandaan ban decoding untuk mobil penumpang, roda pelabelan, bagaimana memilih ban yang tepat pada disk

- Mesin diesel di musim dingin, peluncuran mesin diesel di musim dingin, minyak apa yang akan mengisi mesin diesel di musim dingin, tips berguna

- LED backlight dari mobil, lampu latar dari bagian bawah mobil, lampu latar kaki di dalam mobil, lampu latar di pintu mobil, lampu latar mobil baik-baik saja

- Ban yang dipulihkan, ban bus, pelindung ban yang dipulihkan, dapatkah saya menggunakannya

- Pilih Ban Musim Dingin, yang merupakan ban musim dingin, yang tekanan pada ban musim dingin harus ditandai dengan ban musim dingin, bagaimana memilih ban musim dingin yang tepat, ban musim dingin terbaik 2019

- Rel rel kemudi, ketukan rak kemudi, alasan knock dan perbaikan rak kemudi melakukannya sendiri

- Ban mobil tanpa roti, satu set untuk perbaikan ban tubeless, perbaikan ban bebas meriam melakukannya sendiri

- Ban Rusia, Ban Rusia Musim Dingin, Ban All-Seas Rusia, Voronezh Amtel Ban, Ban "Ban Matador Omsk", Ban Kama adalah bus kelas dunia

- Cara membuka mobil tanpa kunci. Kehilangan kunci dari mobil apa yang harus dilakukan, kunci dari mobil di dalam mobil

- Ban hening, ban musim dingin yang tenang, bus bertabur yang tenang, yang ban untuk memilih, ikhtisar ban

- Ban dan keamanan, keamanan bus, mengapa perlu untuk terus memantau ban mobil

- Aturan mengemudi mobil yang aman di tengah hujan dan lumpur, mengemudi mobil yang aman untuk pemula

- Konverter karat yang lebih baik untuk mobil, konverter karat untuk memilih cara menggunakan transduser karat, profesional

- Memoles tubuh mobil melakukannya sendiri, bagaimana memilih pasta pemoles, tips bermanfaat

- Daya tahan engine, kehidupan engine, cara memperpanjang kehidupan mesin

- Ketuk mobil. Ketukan saat menggerakkan mobil. Apa yang bisa mengetuk mobil. Cara menentukan penyebab ketukan.

- Mobil ABS, apa itu mobil ABS, kerusakan sistem abs, diagnostik ABS

- Menyalip mobil ketika Anda dapat mulai menyalip mobil, aturan aturan lalu lintas

- Pompa Bahan Bakar VAZ 2110, VAZ 2110 Skema Pompa Gas, VAZ 2110 Perangkat Pompa Bahan Bakar, VAZ 2110 Perbaikan pompa bensin,

- Antena otomotif untuk radio, perangkat antena otomotif, antena mobil melakukannya sendiri

- Suspensi depan Kalina, suspensi depan perangkat Kalina, ketuk suspensi depan Kalina, perbaikan suspensi depan Kalina

- Minyak peredam kejut, peredam kejut minyak terbaik, pemompa peredam kejut minyak, cara memompa peredam kejut minyak dengan benar

- Kerusakan kopling, menyentuh kopling, menyebabkan kerusakan kopling, cara menghilangkan

Komentar