Otomotiv meme yanma odası içerisinde yakıtın doğrudan püskürtülmesi sorumlu olan bir cihazdır. Bugüne kadar, bu cihazın çeşitli değişiklikler vardır. Bu konuda makalede.

İçerik

- Enjeksiyon sistemi oluşur olan yakıt enjeksiyon sistemi,

- Motorda memelerini gerekenler için doğrudan enjeksiyonlu veya

- Nozul türleri ve amacı

- Elektromanyetik meme, cihaz ve çalışma prensibi

- bağlamda Benzin meme

- Dizel meme, dizel motor püskürtme, cihaz ve çalışma prensibi

- Piezoforun, cihaz

- işin Piezohoroforsunk, ilke

- Piezohoroforsunk, haysiyet

Enjeksiyon sistemi oluşur olan yakıt enjeksiyon sistemi,

yakıt sistemi, eleman içerir:

- En ampuller.

- Yakıt tankı.

- Benzin pompası.

- Yakıt filtreleri.

- hava ve yakıt karıştırılması için cihaz.

- Basınç kontrolü Yakıt.

- Emme manifoldu.

- Hava filtresi.

- Sensörler.

- Egzoz gazlarının gürültü susturucu.

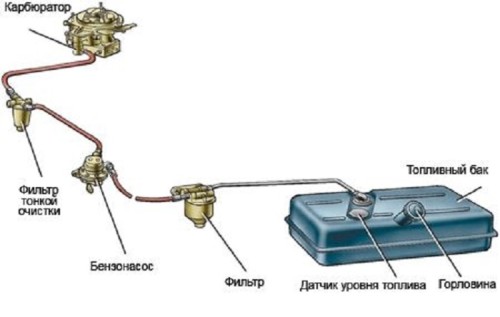

hava ve yakıt karıştırmak için kullanılan cihaza bağlı olarak, yakıt sistemlerinin üç tipi vardır:

- Şarj edilebilir yakıt sistemi - dizel motorlarda kullanılan.

- Karbüratör yakıt sistemi - karbüratör motorlarda kullanılan.

- Enjektör yakıt sistemi - benzin motorlarında kullandı. Bu durumda, hava ve yakıt karıştırılması için meme için sorumludur.

Motorda memelerini gerekenler için doğrudan enjeksiyonlu veya

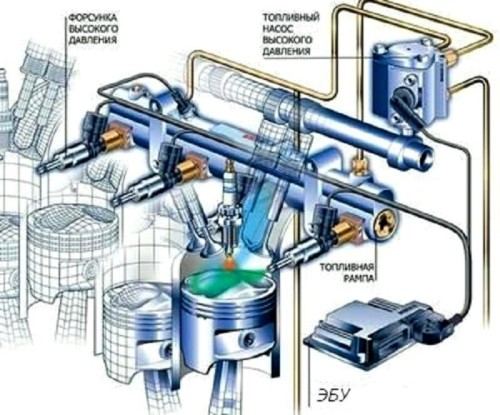

Doğrudan enjeksiyon, yağın silindirlere doğrudan enjekte edildiği dağıtılmış yakıt enjeksiyonunun modernasyonudur. Nozül, yakıt pompası ile motor arasındaki ana bağlayıcı bileşendir. Nozulların asıl amacı:

- Motora sağlanan yakıtın doğru dozunun sağlanması.

- Karışımın doğru jeti (miktar, basınç, açı) sağlamak.

Meme türleri ve amaçları

Elektromanyetik nozul, cihaz ve iş prensibi

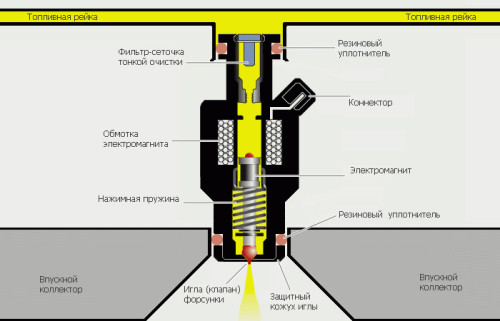

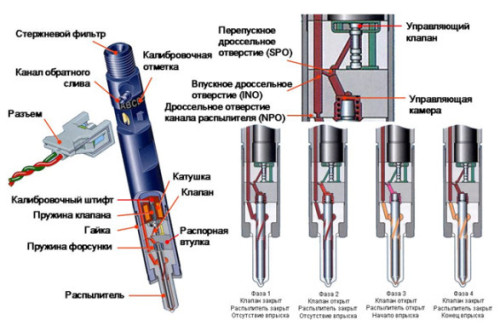

Bu tür elektromanyetik cihazlar, doğrudan enjeksiyonla da dahil olmak üzere benzinli motorlarda bir kural olarak kullanılır. Bu tür ekipman, aşağıdakilerden oluşan oldukça basit bir tasarıma sahiptir:

- Meme nozülü.

- İğne.

- Davada mühür.

- Memenin gövdesi.

- Elektromıknatısından çapa.

- Özel bahar.

- Elektromanyetik uyarma sargısı.

- Elektrik konnektörü.

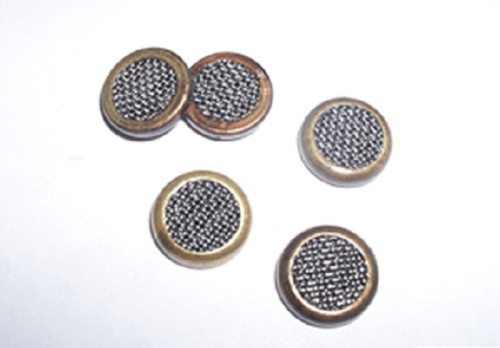

- Örgü filtresi.

Nozül sıçrayan yakıt gerçekleştirir. Bu bileşenin çalışmasının kalitesinden ötürü, tüm cihazın çalışmasına bağlıdır. Mesh filtresi, memeden geçen yakıtı filtreler.

Daha önce döşenmiş algoritmaya karşılık gelen ECU, istenen anda valf uyarılmasının sargısına voltaj beslemesini sağlar. Bunun işleminde, bir elektromanyetik alan, bahar kuvvetinin üstesinden gelinmesi, ardından nozülü bir iğneli bir bağlantıyı geciktirir. Sonuçta bu yakıt enjeksiyonu. Gerilim kaybolduğunda, memenin iğnesi ilkbaharı kullanarak eyere geri döner.

Bağlamda benzinli nozül

- Örgü filtresi.

- Meme nozülü.

- Fok.

- İğne memesi.

- Memenin gövdesi.

- Çapa elektromıknatıs.

- Koşum sarma.

- Bahar.

- Elektrik konnektörü.

Dizel nozul, dizel motor nozulları, cihaz ve çalışma prensibi

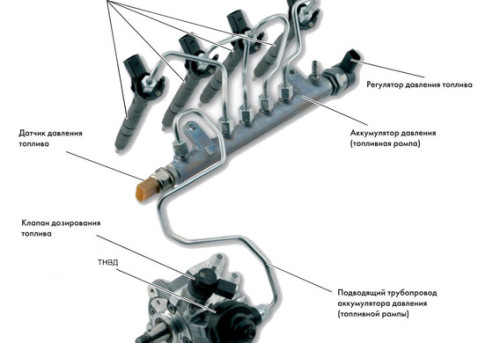

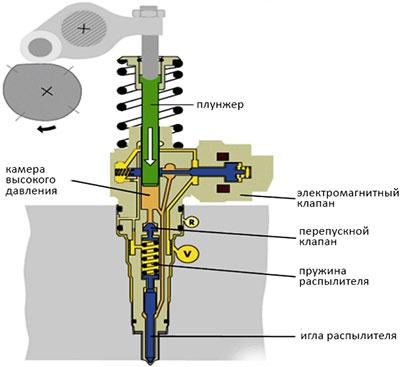

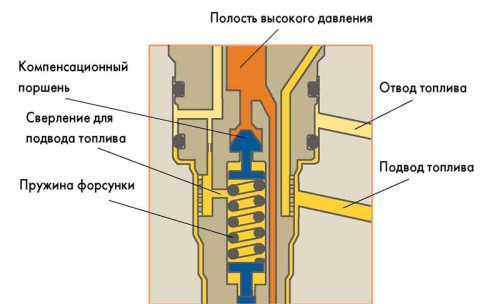

"Common Rail" enjeksiyon sistemi ile donatılmış olanlar da dahil olmak üzere dizel motorlarda, elektrohidrolik nozullar kullanılır. Bu cihazın tasarımı, bir elektromanyetik valf, bir kontrol odası, ayrıca bir drenaj ve giriş şoku içerir.

Bu tür bir donanımın çalışma prensibi, enjeksiyon sırasında yanı sıra, sonlandırılmasından sonra yakıt basıncının kullanımına dayanır. İlk pozisyonda, solenoid valfı tamamen kapalı ve enerji beslenir, cihazın iğnesi, kontrol odasındaki yakıt pistonu üzerindeki bir basınçla eyere bastırılır. Bu pozisyonda yakıt enjeksiyonu yapılmaz. İğnedeki yakıtın basıncının, bu durumda, temas alanlarındaki farkın bir sonucu olarak pistonda üretilen daha az basınç.

ECU komutundan sonra, solenoid valf tetiklenir ve tahliye gazı açılır. Kumanda haznesinde bulunan yakıt, gaz kelebeğinde drenaj otoyoluna akar. Giriş şoku, giriş hattındaki ve kontrol odasındaki en hızlı basma seviyelerinin bir engeldir. Yavaş yavaş pistonun üzerindeki basınçta bir azalma vardır, ancak, iğnede egzersiz yapan yakıt basıncı değişmez ve yakıtın enjeksiyonunu ve enjeksiyonunu ortaya çıkarır.

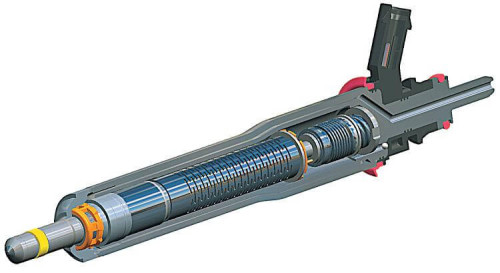

Piezoforun, cihaz

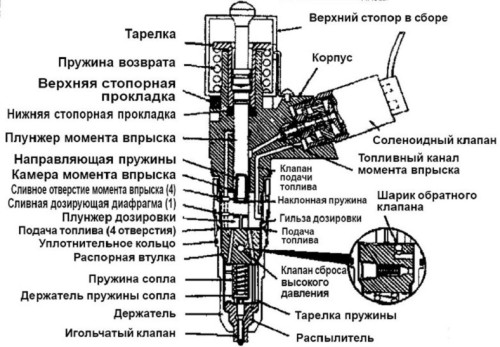

Piezoquorming'in tasarımı, bu tür bileşenleri içerir:

- Yakıt besleme kanalı.

- Elektrikli nozul konektörü.

- Mikrofilter.

- Kanal ıslahı.

- Piezoelement.

- Piston itici.

- Vana pistonu.

- Yay valfi.

- Anahtarlama vanası.

- Boğulma bloğu.

- Bahar iğnesi püskürtücü.

- Yanmaz Yıkayıcı.

- Püskürtücünün iğnesi.

Piezohoroforsunk, iş prensibi

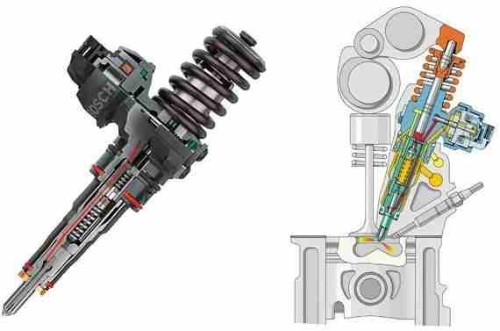

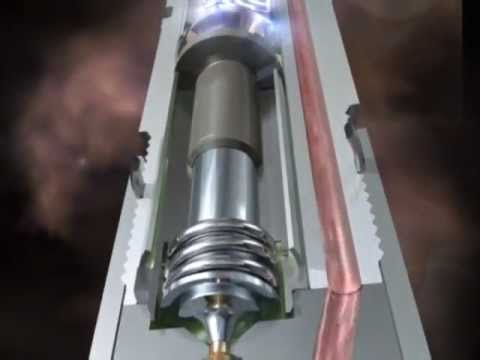

Nozülün kontrol vanasının çalışması, örneğin gaz çakmaklarında kullanılan iyi bilinen bir piezoelektrik etkiye dayanır. Adamın parmağı, çalışma bileşenini dielektrikten deforme eden bir düğmeye basar. Sonuç olarak, şarj gazı iltihaplandırmak için kullanılır.

Piezoelektrik nozullarda, t. N. Ters piezoelektrik etkisi. Gerilim, malzemenin deformasyonuna katkıda bulunan Dielektrik'e beslenir. Valf çubuğu, akımın memeye beslenmesi durumunda tırmanabilen, buna bağlanır.

Piezohoroforsunk, onurlu

- Yüksek verimli nozullar.

- Motor çalışma sürecinde gürültüyü azaltma.

- Enjeksiyon basıncını değiştirme yeteneği.

- Memenin hızını arttırın.

İlgili Malzemeler

- Soba 2110, Kötü Sıcak Soba 2110, Vaz 2110 Isıtma Sistemi, Isıtma Sistemini Tamir Vaz 2110 Kendi Elleriyle

- Vaz 2114 Soba Soğuk Hava, Soba 2114, Kötü Sıcak Soba Vaz 2114, Cihaz ve Isıtma Tamiri Vaz 2114 Do-it-kendiniz, Soba Vaz 2114 Çıkarma

- Arabayı nasıl altsayılır? Nasıl bir kriko koymak. Arabalar için krikolar türleri.

- VAZ 2109 Sigorta Bloğu, Vaz 2109 Sigorta Bloğu Karbüratör, Vaz 2109 Sigorta Bloğu Enjektör, Eski Vaz 2109 Sigorta Bloğu, Vaz 2109 Sigorta Bloğu, Vaz Sigorta Bloğu 2109

- Araba egzoz gazı katalizörü, hatalı katalizör, catalizörün arızaları ve eksileri, flaimeenCitel'deki katalizörü nasıl değiştirilir

- Soba üfleme soğuk air vaz 2114, kötü bir şekilde ocak vaz 2114 üfleme, neden kötü bir şekilde ocak vaz 2114 üfleme

- Arabanın sahibini aracının sayısına göre nasıl öğrenilir, arabayı trafik polisi makinesinin sayısına göre kontrol edin, arabanın aracının devlet numarası ile ücretsiz olarak kontrol edin.

- Kullanılan lastikler, faydalı ipuçları nasıl seçilir

- Kış arabası yolu, kışın binek otomobil lastiklerinde basınç, kışın araba için iyi bir batarya, ister kışın araba sıcak olsun

- Kışın, araba kötü başladı. Kışın bir araba nasıl yapılır, kışın arabayı ısınmanız gerekir mi, Faydalı İpuçları

- Ekonomi Yakıt Tüketim Makineleri, En ekonomik araç tüketimi

- Binek otomobilleri için lastikler, otomobil lastiği etiketleme, artık binek otomobil lastik koruyucusu, araba marka üzerinde bir lastik, araba lastik sırt deseni

- Çalışma İletim İşlemi, Mekanik Şanzıman Debriyaj Çalışması, Manuel Şanzıman ile Sürüş, Faydalı İpuçları

- Arka Kiriş Peugeot 206 Sedan, Arka Işın Cihazı Peugeot 206. Arka Kiriş Peugeot 206 Arızalı, Arka Işın Tamiri Peugeot 206

- Kışın dizel yakıt, kışın dizel yakıt katkı maddesi, en iyi dizel yakıt nasıl seçilir

- Dizel Kış başlamaz. Kışın dizel nasıl başlayabilirsiniz, kışın dizel ısıtma.

- Japon Bridgestone Lastikleri, Kış Çivili Bridgestone Lastikleri, Bridgestone Lastikleri Marka

- Binek otomobilleri, etiketleme tekerlekleri için tire işaretleme, disklerde doğru lastiklerin nasıl seçileceği

- Kışın dizel motor, kışın dizel motorun piyasaya sürülmesi, kışın bir dizel motorda doldurulacak yağ, faydalı ipuçları

- Arabanın LED aydınlatması, arabanın alt kısmının arka ışığı, arabadaki bacakların arka ışığı, arabanın kapısındaki arka ışık, arabanın arka ışığı iyi

- Kurtarılan lastikler, otobüs lastiği, restore edilmiş lastik koruyucusu, onları kullanabilir miyim

- Kış lastikleri olan kış lastikleri olan Kış lastikleri olan kış lastikleri, kış lastikleri ile işaretlenmelidir, doğru kış lastikleri, en iyi kış lastikleri 2019

- Direksiyon ray rayı, direksiyon rafının çalınması, direksiyon rafının vurulması ve onarılmasının nedenleri kendin yap

- Cameless Car Lastikleri, Tubeless lastiklerinin tamiri için bir set, topsuz lastiğin tamiri kendin yap

- Rus lastikleri, rusça lastikler kış, Rus tüm sezon lastikler, voronezh amtel lastikleri, lastikler "Matador Omsk lastiği", Kama-lastikler birinci sınıf otobüs

- Anahtarsız bir araba nasıl açılır. Arabanın anahtarı ne yapmalı, arabanın içindeki arabanın anahtarı

- Sessiz lastikler, sessiz kış lastikleri, sessiz çivili otobüs, hangi lastikleri seçecek, genel bakış lastikleri

- Lastik ve güvenlik, otobüsün güvenliği, neden araba lastiklerini sürekli izlemek için gereklidir?

- Yağmurda ve slush, arabanın güvenli sürüşü, yeni başlayanlar için arabanın güvenli sürüşü kuralları

- Otomobiller için daha iyi olan Pas Dönüştürücü, pas dönüştürücülerin nasıl kullanılacağını seçmek için pas dönüştürücüler, profesyoneller

- Otomobilin vücudunu parlatmak, kendiniz yapın, parlatma macunu nasıl seçilir, Faydalı İpuçları

- Motor dayanıklılığı, motor ömrü, motor ömrünü uzatma

- Arabayı vur. Arabayı hareket ettirirken vurun. Arabayı çalabilir. Knock'un nedeni nasıl belirlenir.

- ABS araba, ABS araba nedir, ABS sistem arızası, ABS Teşhis

- Bir arabayı süzmeye başlayabildiğinizde, trafik kurallarının kuralları

- Yakıt Pompası Vaz 2110, Vaz 2110 Benzin İstasyonu Şeması, Vaz 2110 Yakıt Pompası Cihazı, Vaz 2110 Benzin İstasyonu Onarımı,

- Radyo, otomotiv anten cihazı için otomotiv antenler, araba anteni kendin yap

- Ön Süspansiyon Kalina, Cihaz Ön Süspansiyon Kalina, Ön Süspansiyon Kalina, Ön Süspansiyon Tamiri Kalina Onarım

- Amortisör Yağı, En İyi Yağ Amortisörleri, Pompalama Yağ Amortisörleri, Düzgün Pompa Yağ Amortisörü Nasıl Yapılır

- Debriyaj arızaları, debriyaj dokunuşları, bir debriyaj arızasına neden olur, nasıl ortadan kaldırılır

Yorumlar